by Howard Penrose, Ph.D., CMRP | Oct 9, 2020 | Electrical Reliability, Motors & Drives

In Part I of this short series (Oct. 3, 2020), we pointed to certain stator defects coinciding with specific signatures that have been presented through observation. Regarding the induction motor itself, while substantial research on the defect signature associated...

by Howard Penrose, Ph.D., CMRP | Oct 3, 2020 | Electrical Reliability, Motors & Drives

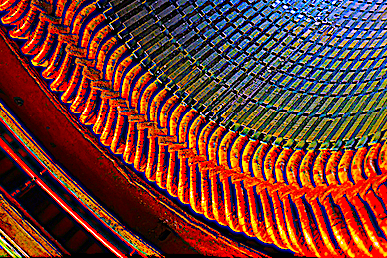

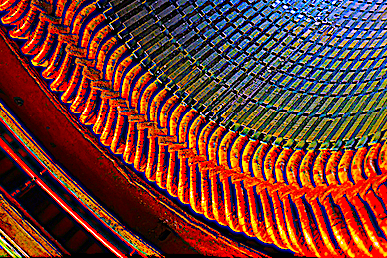

An area that has received limited research analysis within the topic of Electrical and Current Signature Analysis (ESA/MCSA) is the stator-slot signature. It’s been assumed for many decades that the number of stator slots times the running speed with different...

by Howard Penrose, Ph.D., CMRP | Sep 26, 2020 | Electrical Reliability, Motors & Drives

Over the past few decades, the general discussion in industry has been that you cannot perform offline electrical- or motor-current-signature analysis (ESA and MCSA, respectively) on equipment in no-load conditions. In fact, some publications have suggested the need...

by Howard Penrose, Ph.D., CMRP | Sep 17, 2020 | Electrical Reliability, Motors & Drives

In this week’s article on Electrical Signature Analysis (ESA), we discuss the issue of a 1X rpm current reading when dealing with belted applications. For this example, the motor is a 15 hp, 1765 rpm, 460 Vac, 18 Amp unit with 40 rotor bars (RB) and 48 stator...

by Howard Penrose, Ph.D., CMRP | Sep 11, 2020 | Electrical Reliability, Motors & Drives

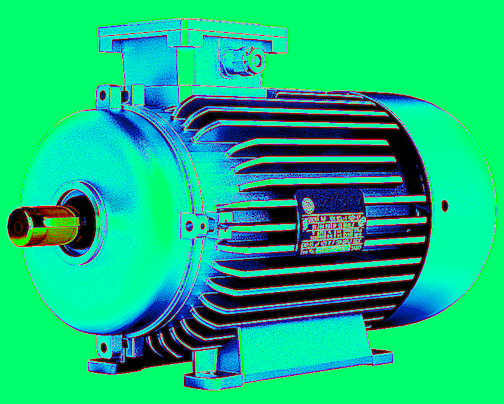

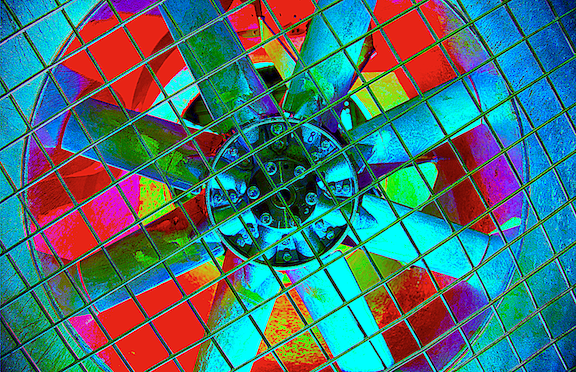

While sometimes referred to as Motor Current Signature Analysis (MCSA), which involves collection of motor current data only, Electrical Signature Analysis (ESA) utilizes both voltage and current data. This includes values, phase impedance, power harmonics, and other...

by Howard Penrose, Ph.D., CMRP | Sep 4, 2020 | Electrical Reliability, Motors & Drives

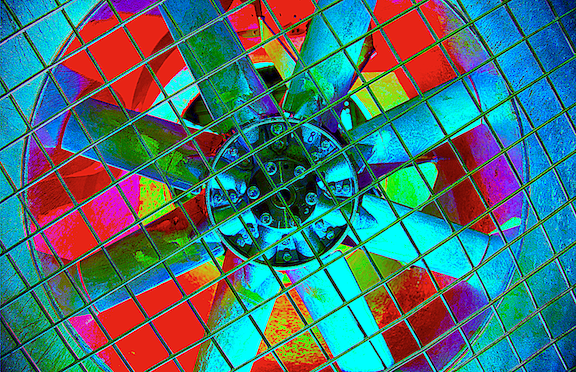

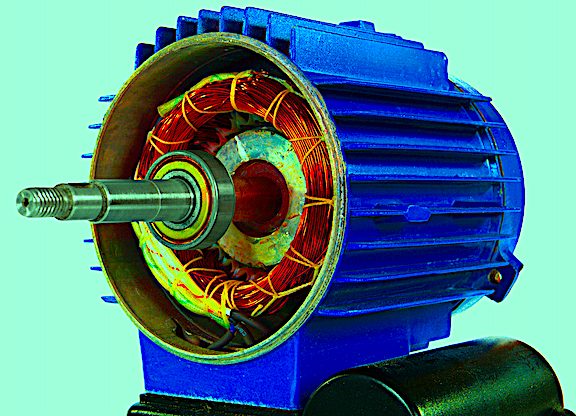

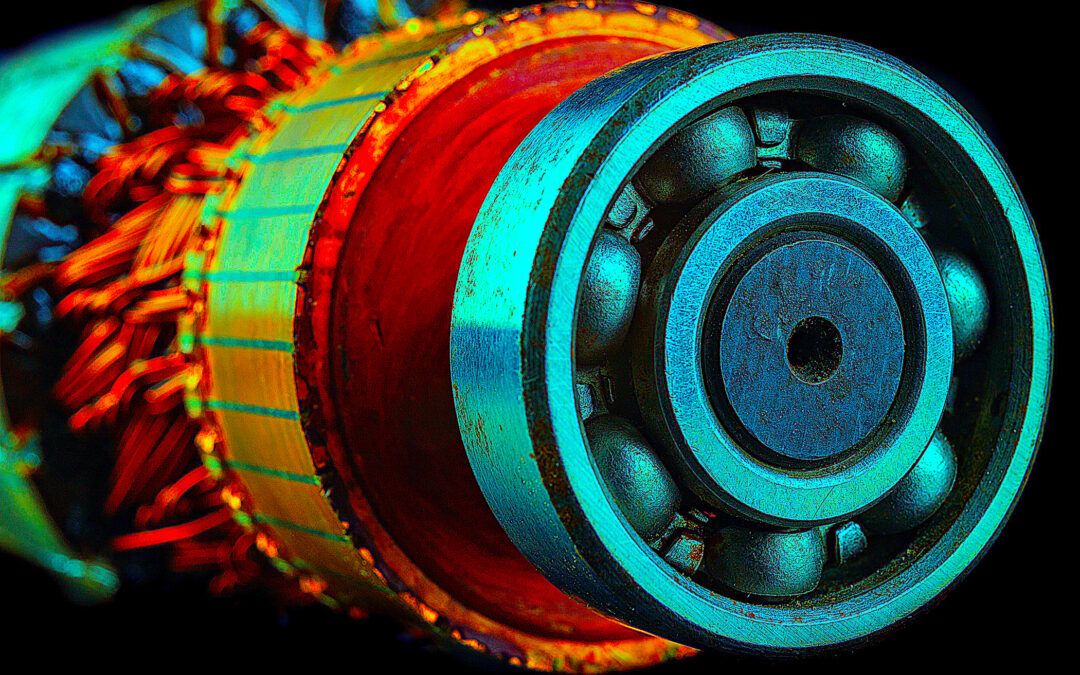

Rotor-bar failures are not common in properly applied systems. In this short case study, we follow a 4000-hp motor without starting restrictions to rotor bar failure. Lessons learned include demonstration of the fact that load does not impact the relative...

by Howard Penrose, Ph.D., CMRP | Aug 28, 2020 | Electrical Reliability, Motors & Drives

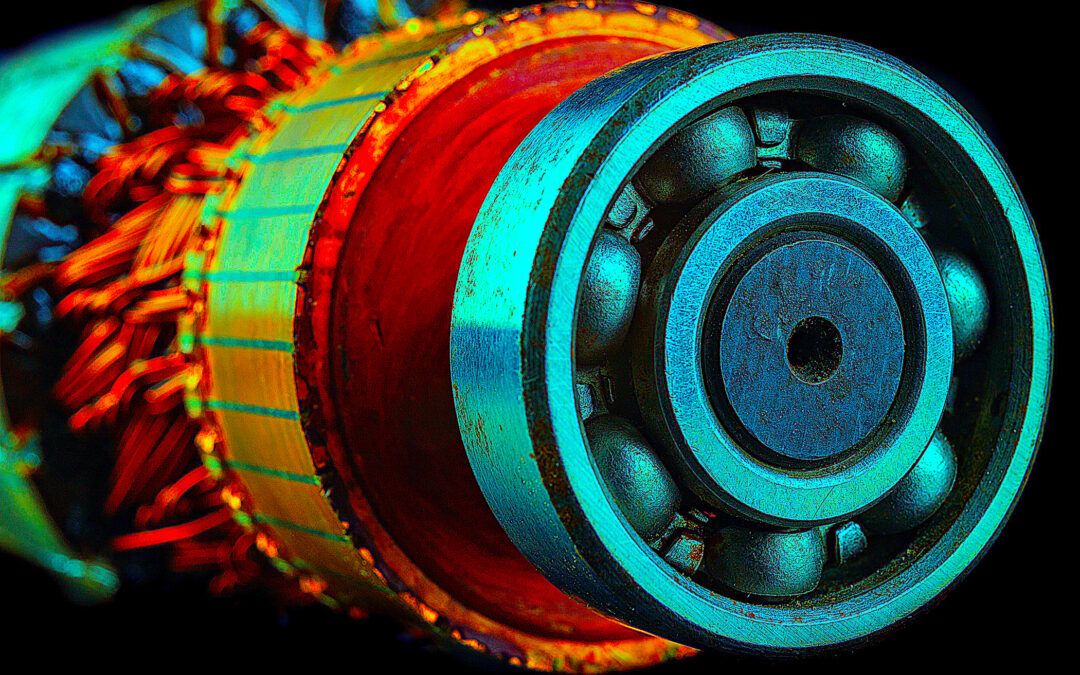

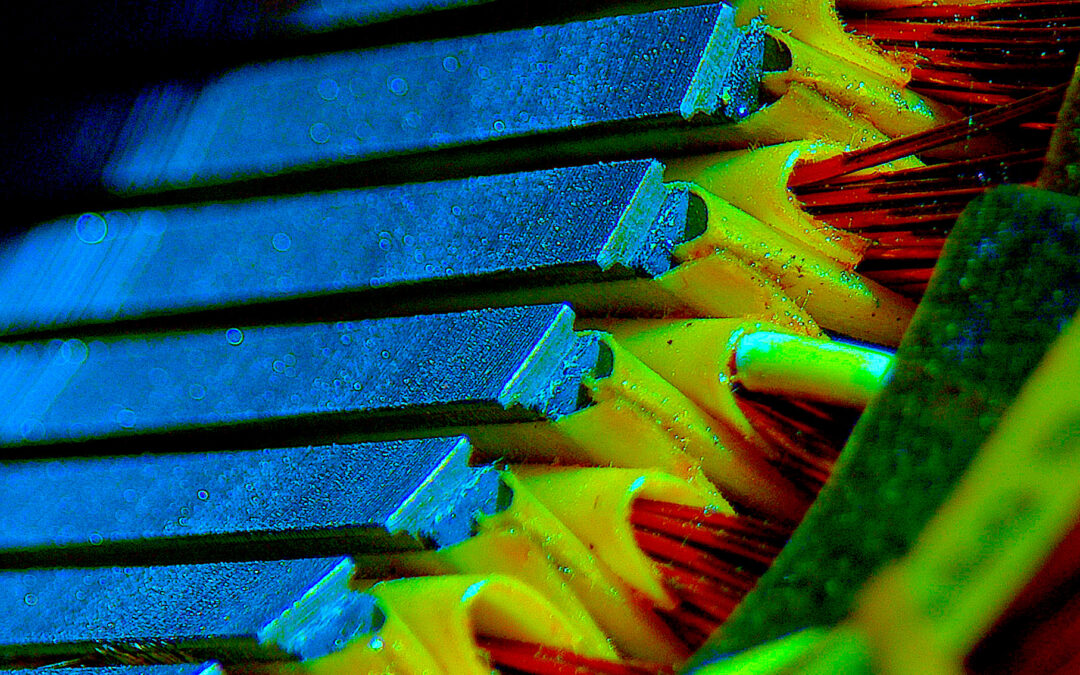

Material wear is a primary cause of degradation of electric machines and driven equipment or powertrain. Wear is caused by either normal operation or abnormal conditions and is also dependent upon the type of equipment and application. The impact of wear in electric...

by Howard Penrose, Ph.D., CMRP | Aug 22, 2020 | Electrical Reliability, Motors & Drives

Let’s start this particular article by looking back at a bit of history. The original concept behind Electrical Signature Analysis (ESA) is based upon the ability to perform voltage signature analysis and Motor Current Signature Analysis (MCSA), with the...

by Howard Penrose, Ph.D., CMRP | Aug 7, 2020 | Electrical Reliability, Motors & Drives

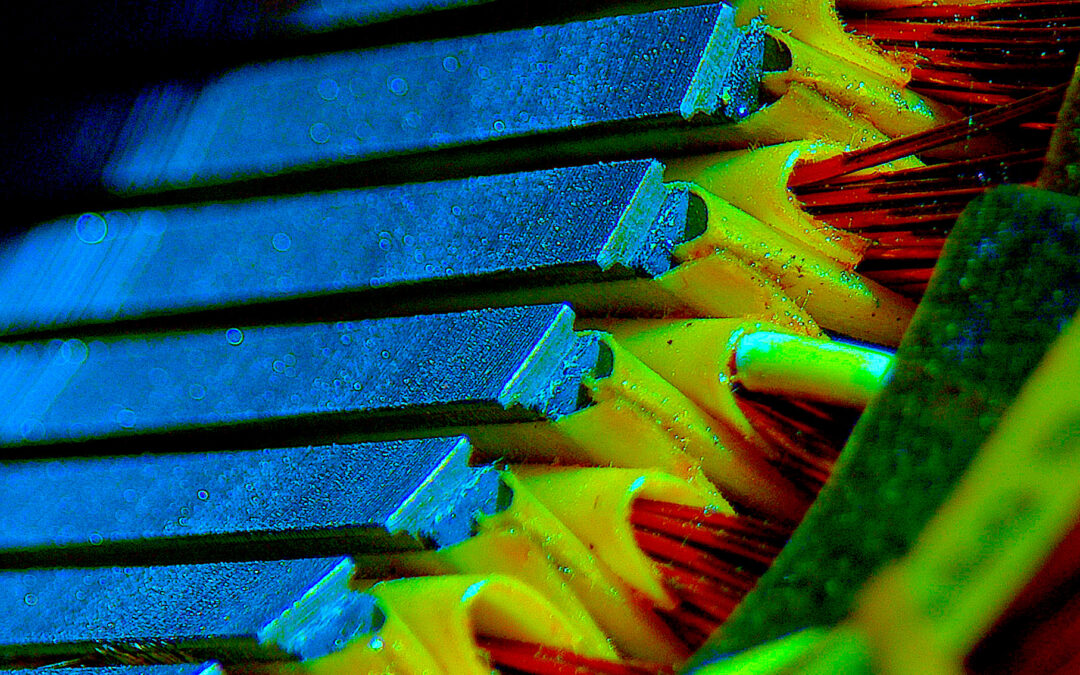

In this week’s article, we’ll discuss insulation systems in more detail and the various high-potential (Hi-Pot) testing types and uses for evaluating electric-motor insulation to ground systems. The use of Hi-Pot testing has been around for over a century,...

by Howard Penrose, Ph.D., CMRP | Jul 25, 2020 | Electrical Reliability, Motors & Drives

The standards working group behind the present edition of IEEE Std 43 made substantial changes in the overall standard, including modifications to temperature normalization to 40 C. This was done to accommodate the many changes and observations in insulation chemistry...