by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jun 13, 2022 | Newsletter Column, RAM Tools & Methods, Workforce Issues

This is the third in an ongoing series of columns with the following theme: “If there were ever a time to get serious about lean manufacturing, it’s now. The vision of doing more with less of everything may very well be the new reality in our upside-down,...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jun 6, 2022 | Newsletter Column, RAM Tools & Methods, Workforce Issues

This is my second installment in a new series on Lean for RAM Professionals. I’ll begin with some points contained in my my previous column, “Is Lean Manufacturing Dead? Surely Not.” (see link below). This theme will continue throughout the series:...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | May 31, 2022 | Newsletter Column, RAM Tools & Methods, Workforce Issues

If there were ever a time to get serious about lean manufacturing, it’s now. The vision of doing more with less of everything may very well be the new reality in our upside-down, post-pandemic world. But it’s not going to be easy for some businesses that...

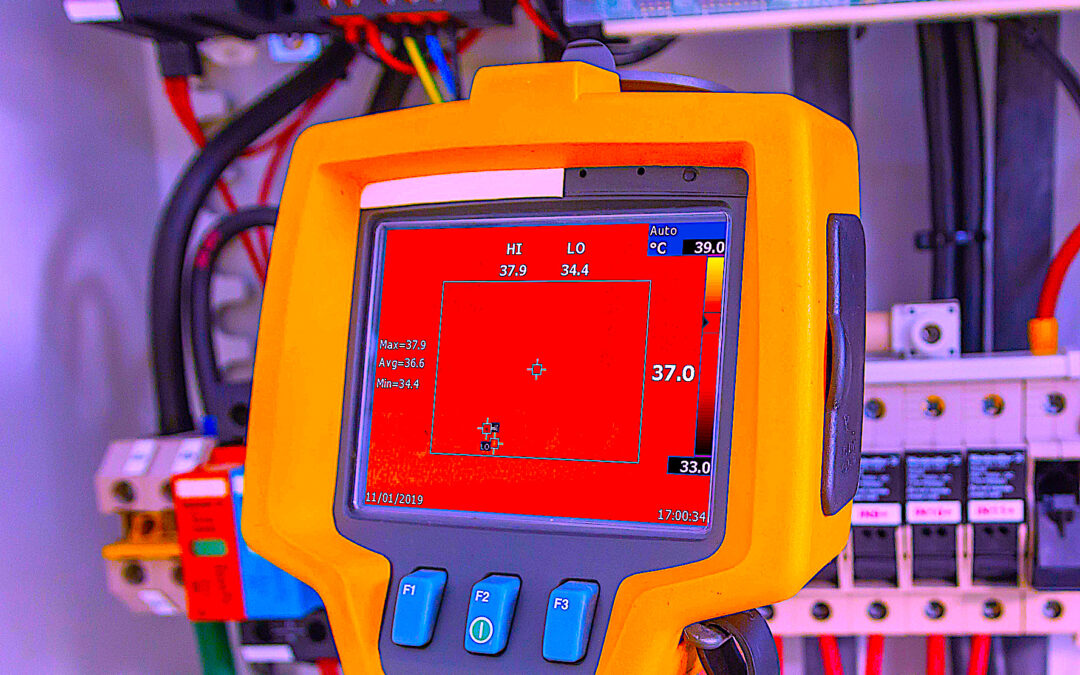

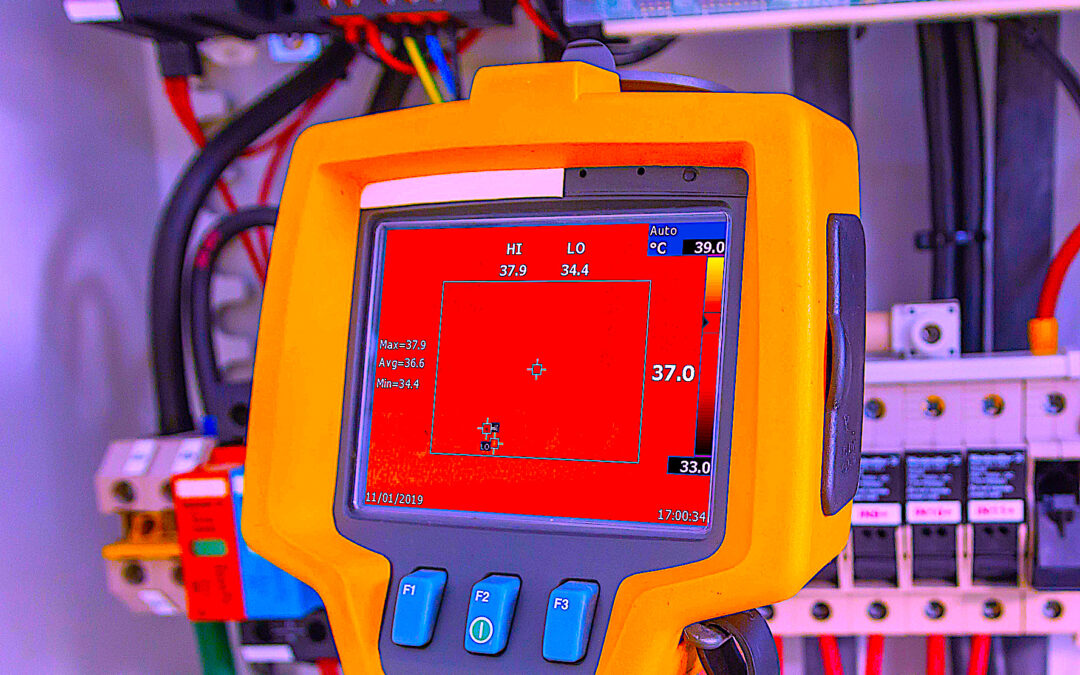

by Jim Seffrin, CMRP | May 22, 2022 | IR Thermography, RAM Tools & Methods

Thermal anomalies are not always as obvious as one might expect. Often, subtle thermal differences can be indicative of major problems. Because infrared thermography is a visual inspection technique, its effectiveness relies on the observation skills of the...

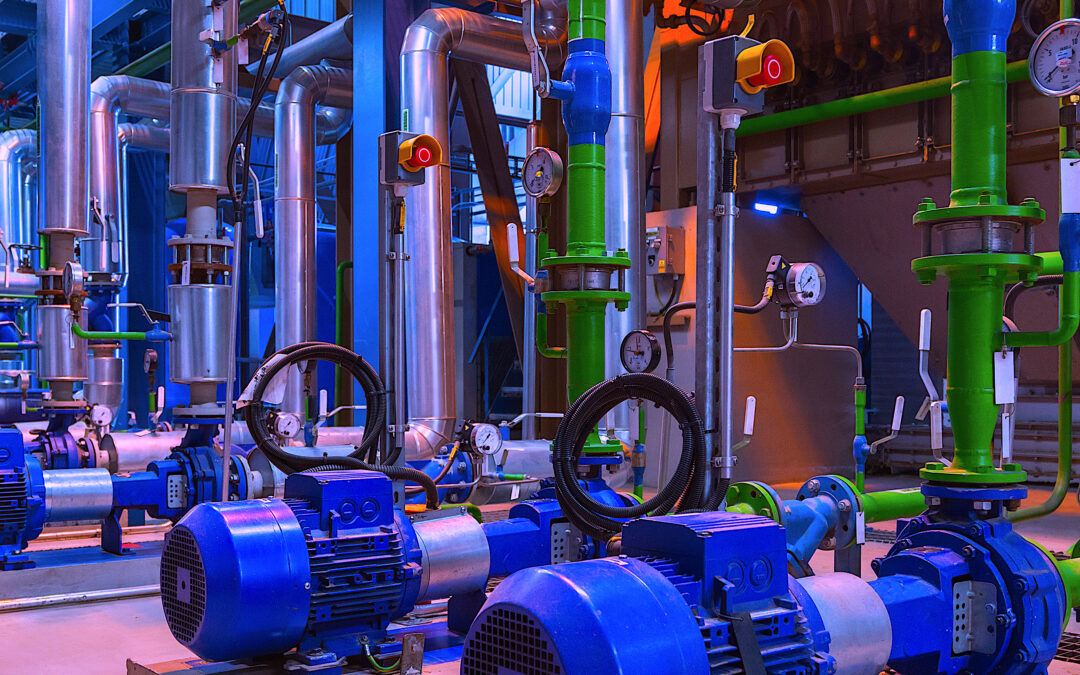

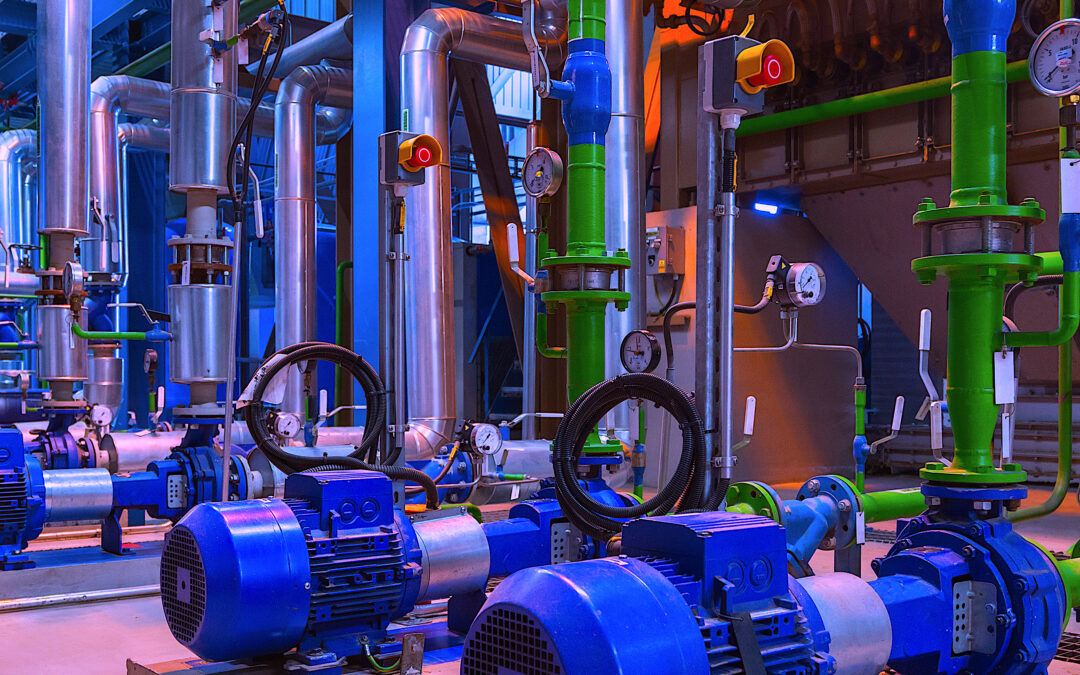

by Heinz Bloch, P.E., Editor | May 8, 2022 | Plant Operations, RAM Tools & Methods, The Bloch Files

For process pumps that consistently meet high reliability expectations, oil rings are rarely (if ever) the most dependable means of lubricant application. They tend to skip around and even abrade (Fig. 1) unless: the shaft system is truly horizontal. However,...

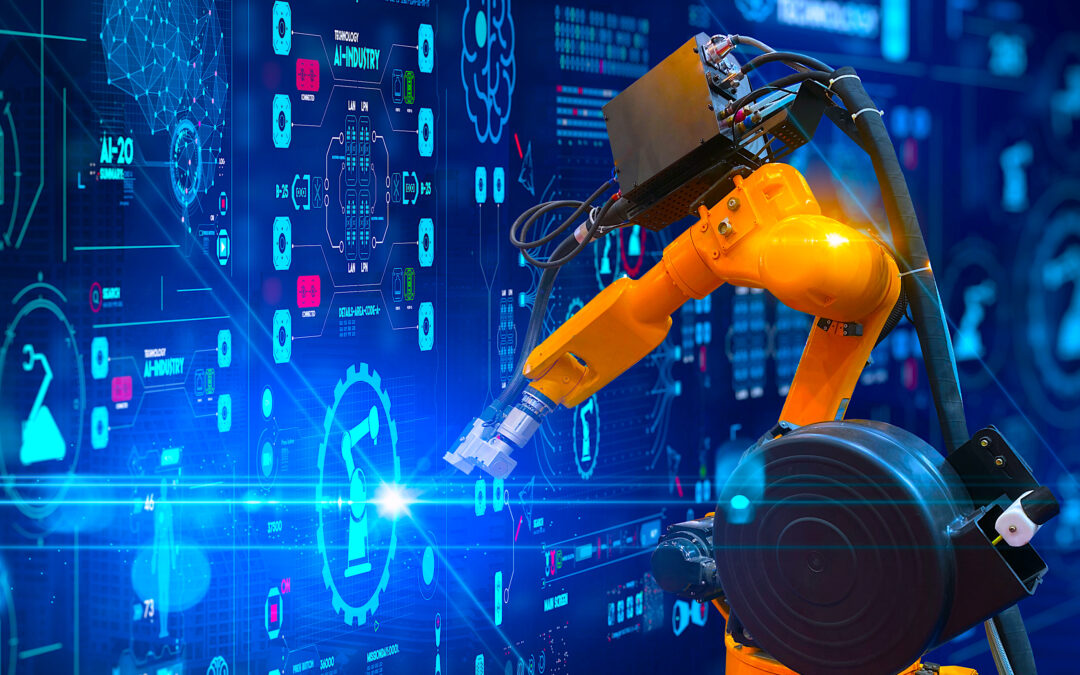

by Howard Penrose, Ph.D., CMRP | May 1, 2022 | Asset Management, RAM Tools & Methods

Big Data. That definitely was the tipping point. Over many years, starting in the 1970s, concepts around replication of human interactions through computers and the terms “neural network” and “Machine Learning (ML)” were found mostly in...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Apr 25, 2022 | Newsletter Column, RAM Tools & Methods

Over time, many businesses have invested in a wide variety of equipment from multiple manufacturers. Such “investments” often have been made by engineering departments in concert with procurement under strict project budget limitations. Cost-conscious procurement of...

by Jim Seffrin, CMRP | Apr 24, 2022 | IR Thermography, RAM Tools & Methods

With interest in renewable energy at an all-time high, photovoltaic (PV) systems have become a common sight worldwide. Infrared inspections can be used for quality-assurance inspections of new installations or to monitor the performance of existing ones. Photovoltaics...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Apr 3, 2022 | Asset Management, RAM Tools & Methods

Over the past six months, I’ve focused on high-level metrics and Key Performance Indicators (KPIs) for asset management. We’ve addressed Mean Time Between/To Failure (MTBF/MTTR), Overall Equipment Effectiveness (OEE) and its associated loss categories, Return on Net...

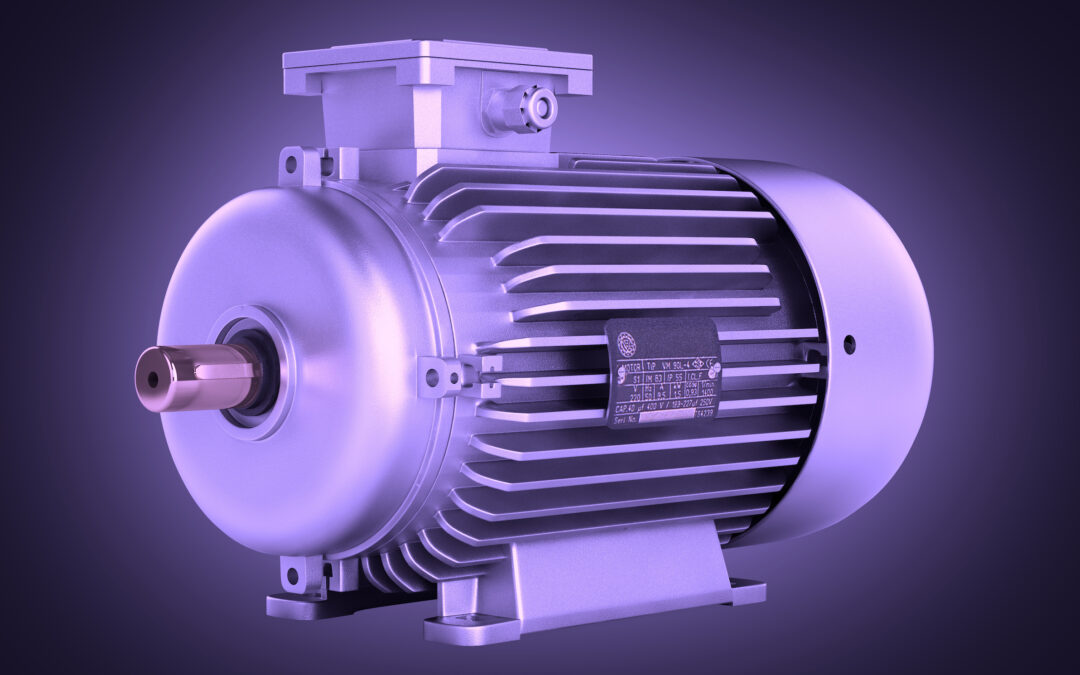

by Howard Penrose, Ph.D., CMRP | Apr 3, 2022 | Electrical Reliability, RAM Tools & Methods

Noise and vibration are measurable losses in the operation of a rotating system, and they can be directly identified in electric motors. As noted in Considering The Direct Energy And Environmental Impact Of Misalignment | THE RAM REVIEW, there are definitive energy...