by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 10, 2021 | Newsletter Column, Planning & Scheduling

As we age, we soon recognize that “time” is the most precious resource we have. This finite resource is also the first currency by which all maintenance activity is controlled, managed, and measured to ensure that the client will receive first-time quality work, on...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Sep 27, 2021 | Asset Management, Planning & Scheduling

In the world of maintenance, we check and measure many things. We do so primarily to recognize and evaluate changes in the desired state of an item or system that’s being monitored and maintained by a preventive-maintenance (PM) program. Ideally, the PM...

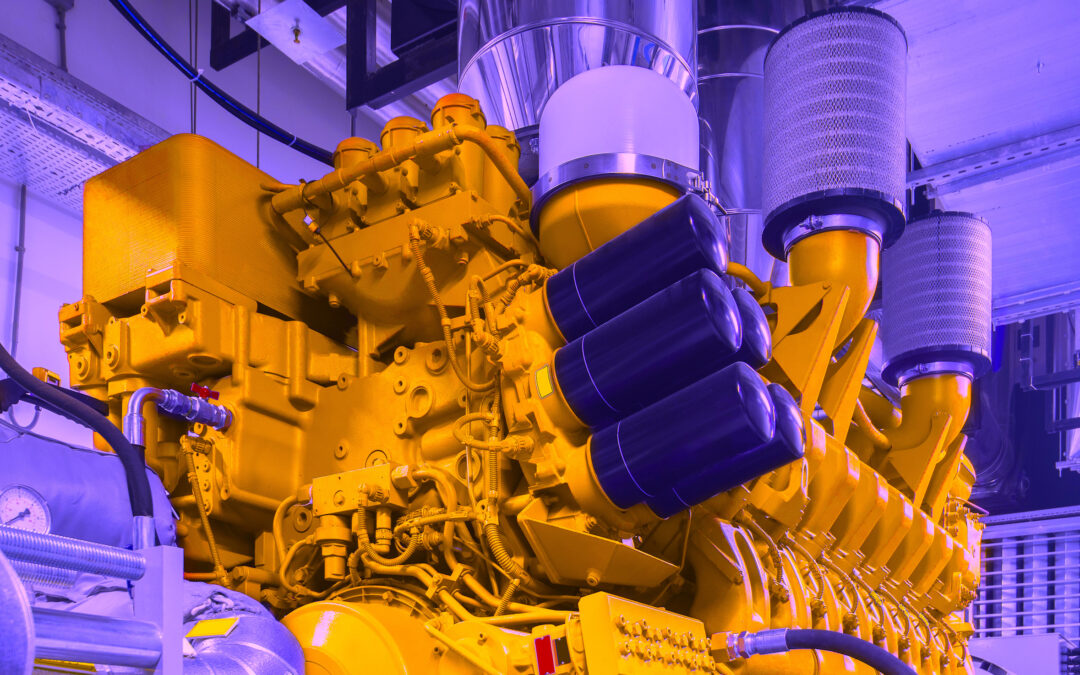

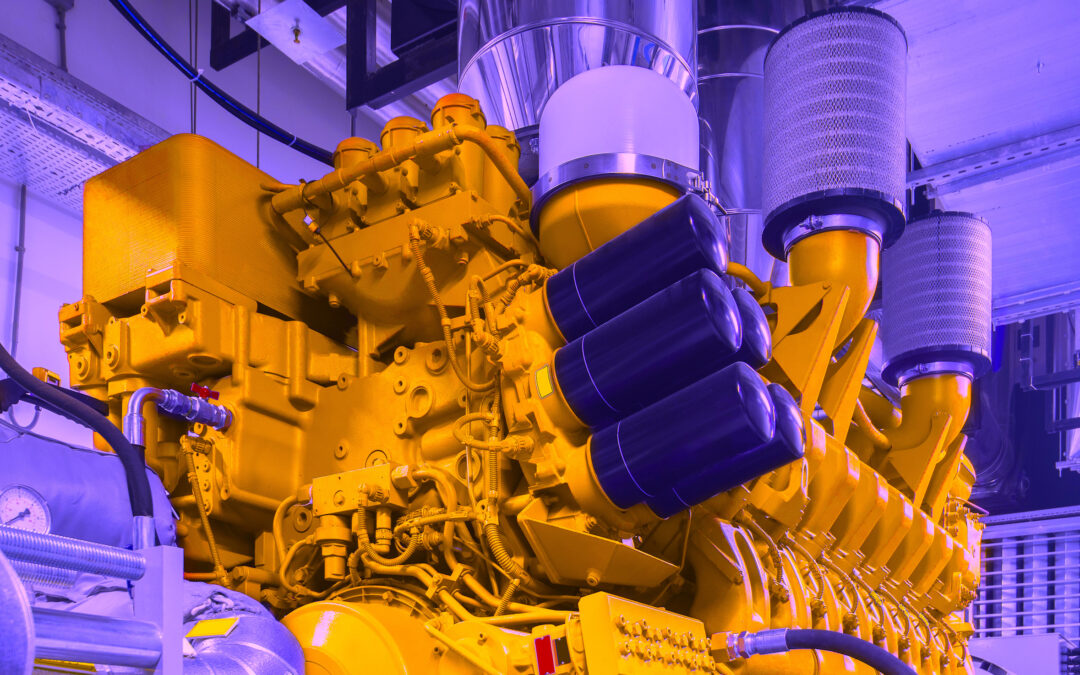

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Sep 19, 2021 | Planning & Scheduling, RAM Tools & Methods

A key element of successful planning and scheduling in plants and facilities is to understand and ensure that critical assets are identified and maintained with higher priority than non-critical ones. Recognizing a critical asset, though, will depend on how a...

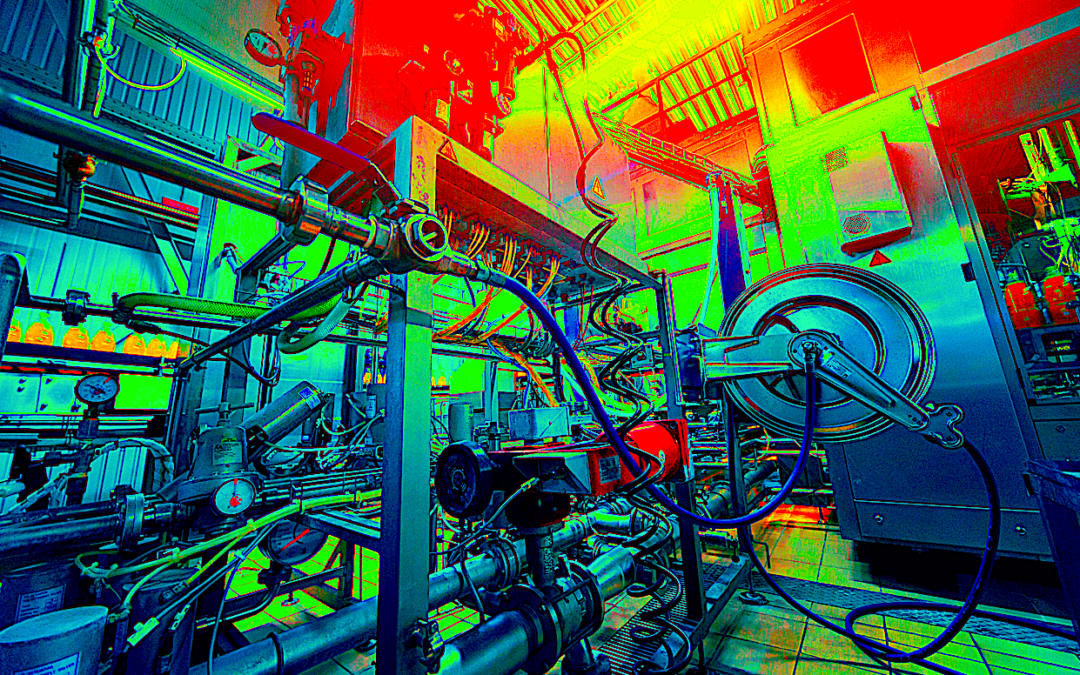

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Aug 2, 2021 | Asset Management, Planning & Scheduling

This week’s article on Overall Materials Effectiveness (OME) concludes our seven-part series on leading metrics that drive proactive behaviors for maintenance and reliability. Along with Overall Planning Effectiveness (OPE), and Overall Scheduling Effectiveness...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Aug 2, 2021 | Planning & Scheduling, Workforce Issues

I’ve shared this story elsewhere over the years, in print and in presentations. That doesn’t matter. The lessons learned from it are worth repeating. As I have often mentioned, motorsports racing, and pit-crew methods can provide invaluable insights for...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Jul 26, 2021 | Asset Management, Planning & Scheduling

In this week’s edition of The RAM Review, we continue our focus on proactive leading metrics. Last week, we addressed Overall Planning Effectiveness (OPE), which helps drive down Mean Time to Repair (MTTR) and drive up work quality. This week, as the above title...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Jul 12, 2021 | Asset Management, Planning & Scheduling

My recent articles on leading metrics designed to drive proactive behaviors at a site have focused on improving Mean Time Between/ To Failure (MTBF/MTTF) of plant assets. These included Overall Inspection Effectiveness (OIE), Overall Lubrication Effectiveness (OLE),...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 31, 2020 | Lubrication Corner, Planning & Scheduling

Talking about the weather is a national pastime. It would appear we are obsessed with it. Yet, many maintenance organizations are often poorly positioned to deal with the problems that weather changes pose for their facilities and machinery, especially when cold...

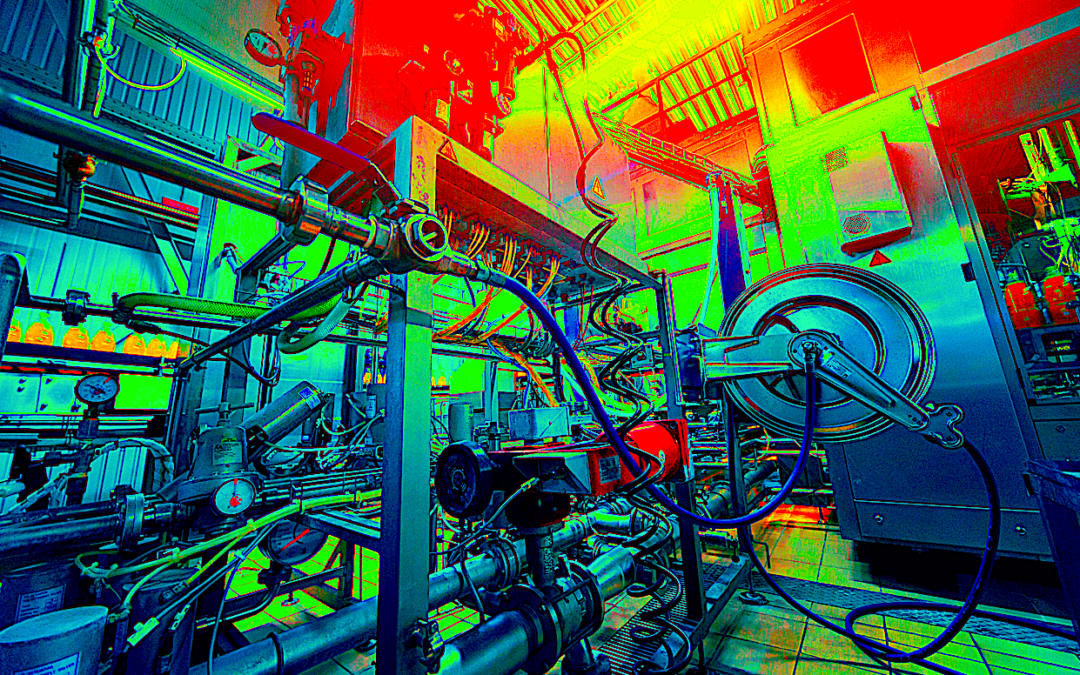

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Sep 25, 2020 | Asset Management, Planning & Scheduling

As the American singer/songwriter Jimmy Buffett observed, “Without geography, you are nowhere!” Making sense of any production or maintenance workflow, process or procedure requires a textual map in the form of a diagram, visual representation, or an ordered text list...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Sep 18, 2020 | Asset Management, Planning & Scheduling

When a maintenance-work request reaches the desk of the planner, his or her first action item is to review the request and determine the priority of the work. This determination will influence whether the planner takes immediate action (Emergency Response) or queues...