by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 26, 2021 | Maintenance Management, Workforce Issues

It’s been said before, “The times they are a’ changin’.” When it comes to today’s RAM arena, that statement is so very true. Industry’s need for quality maintenance-skilled trades has never been more acute. This difficult situation is due, largely,...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Apr 17, 2021 | Maintenance Management, Newsletter Column

If you have ever heard anyone in your organization state, “We’ve always done it that way,” chances are that you’re stuck in a paradigm. And it’s a paradigm that’s likely ill-suited to your current needs and requirements. This paradigm...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Apr 3, 2021 | Maintenance Management, RAM Tools & Methods

Albert Einstein may have said it best: “In the midst of every crisis lies great opportunity.” Those words have special meaning in industry today. As with all catastrophic events, the 2020/21 COVID-19 pandemic has demonstrated, once again, how unprepared...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Mar 6, 2021 | Maintenance Management, Newsletter Column, RAM Tools & Methods

Much attention is paid to the foundational elements that are necessary to ensure equipment and process reliability in plants. Still, in the end, reliability really comes down to people employing tools and materials to effectively execute maintenance plans. That is the...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 31, 2021 | Maintenance Management, Newsletter Column

“Why do we need to fill out these work orders anyway? They’re just trying to micro-manage us. I’m not going to do it. Let’s just do things like we’ve always done.” Sound familiar? Maintenance work orders are often seen as an extra burden to maintainers, as well as to...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 16, 2021 | Lubrication Corner, Maintenance Management

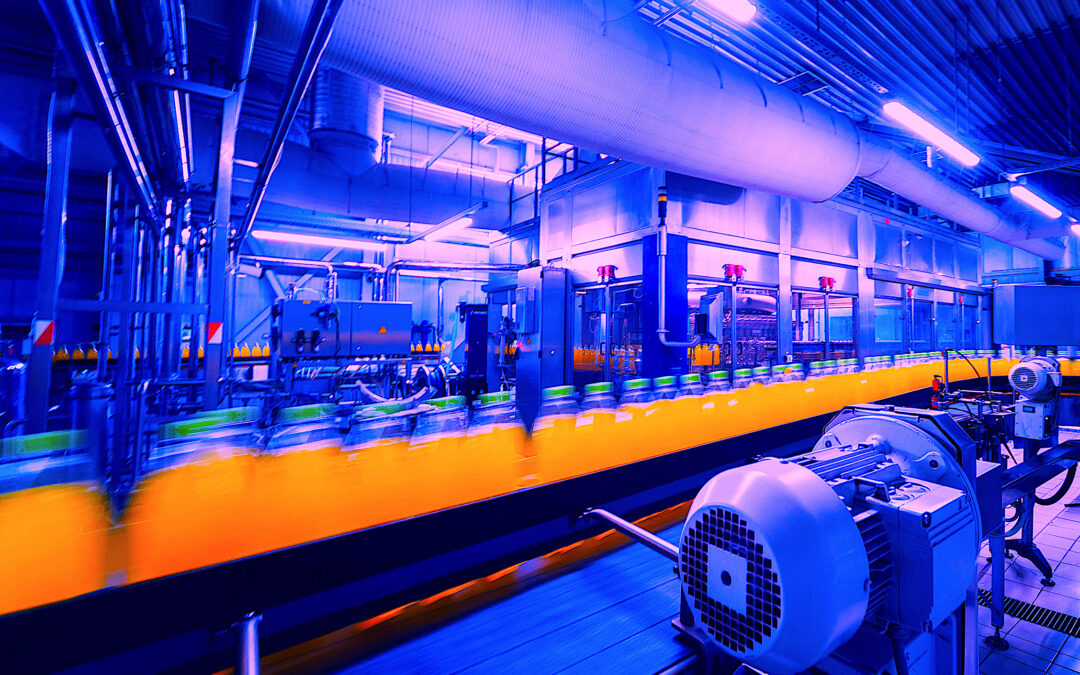

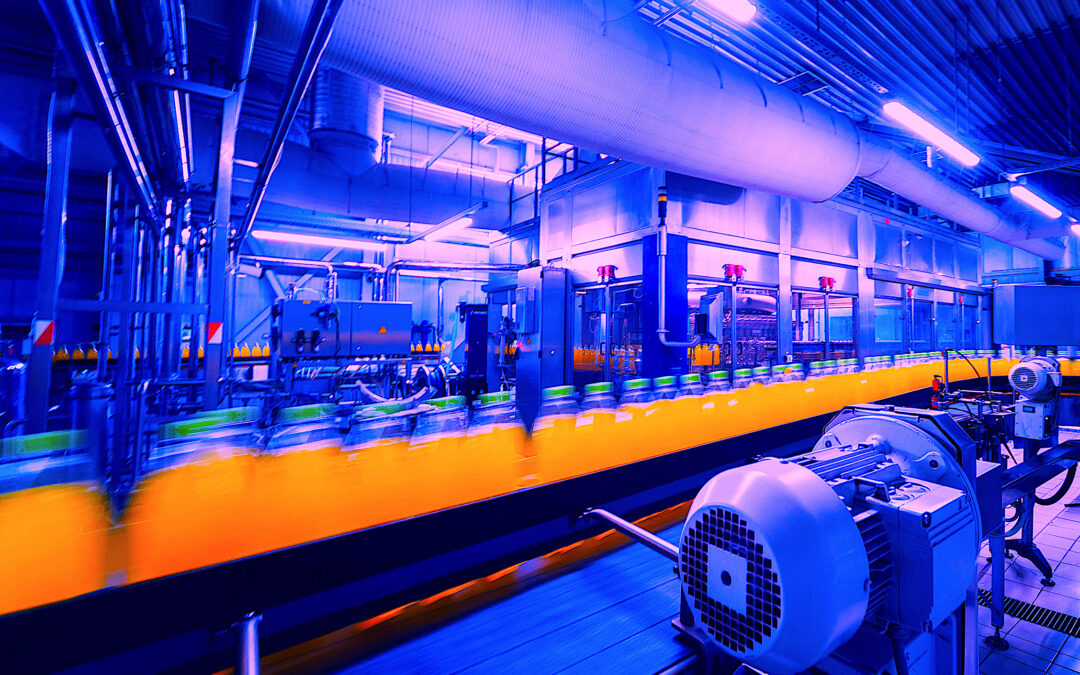

A manufacturing client recently asked me a seemingly difficult question: Does a simple, universal, inexpensive, easy-to-implement maintenance strategy that’s capable of substantially increasing machine reliability and availability actually exist? My answer...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 9, 2021 | Maintenance Management, RAM Tools & Methods

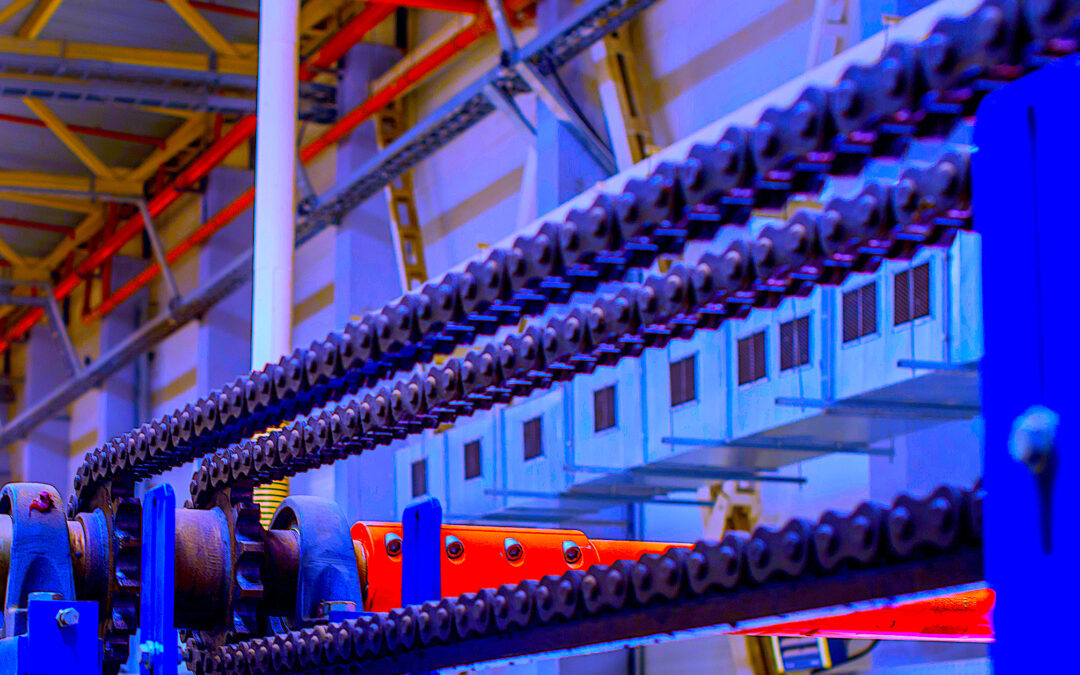

“Procedure-based maintenance” will be invaluable in this era of growing skills shortages and the need for greater machine reliability. Machine complexity, coupled with the impact of the skills crisis and business needs for improved performance, has created a situation...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 2, 2021 | Maintenance Management, RAM Tools & Methods

Many of the tens of thousands of preventive maintenance (PM) and repair work instructions I’ve reviewed over the decades have been sorely lacking in details. That means they’ve left a lot to the mechanics’ discretion. At the same time, many production...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Dec 20, 2020 | Maintenance Management, Newsletter Column

Reliable equipment depends on an alignment of the right things: The right application, operating conditions, duty cycle, operation, maintenance, replacement parts, input/output, performance data, and people following detailed work instructions. This column begins a...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 12, 2020 | Lubrication Corner, Maintenance Management

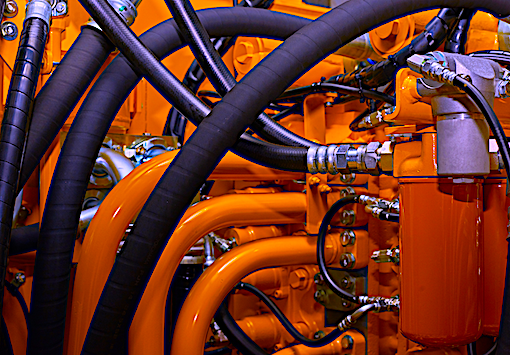

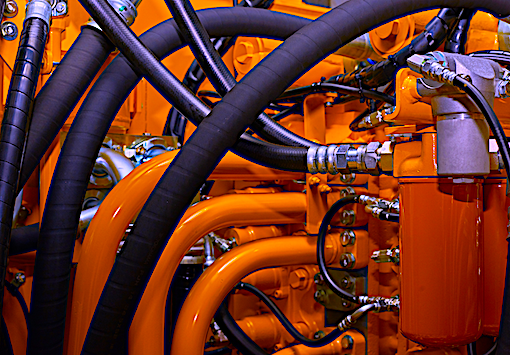

Despite their complexity, hydraulic systems are forgiving in nature. In most cases, they can perform well for a long time before any major or catastrophic failure occurs. Unfortunately, this “creep to failure” quality can promote apathy in production and maintenance...