by Jim Seffrin, CMRP | May 22, 2022 | IR Thermography, RAM Tools & Methods

Thermal anomalies are not always as obvious as one might expect. Often, subtle thermal differences can be indicative of major problems. Because infrared thermography is a visual inspection technique, its effectiveness relies on the observation skills of the...

by Jim Seffrin, CMRP | Apr 24, 2022 | IR Thermography, RAM Tools & Methods

With interest in renewable energy at an all-time high, photovoltaic (PV) systems have become a common sight worldwide. Infrared inspections can be used for quality-assurance inspections of new installations or to monitor the performance of existing ones. Photovoltaics...

by Jim Seffrin, CMRP | Mar 6, 2022 | IR Thermography, RAM Tools & Methods

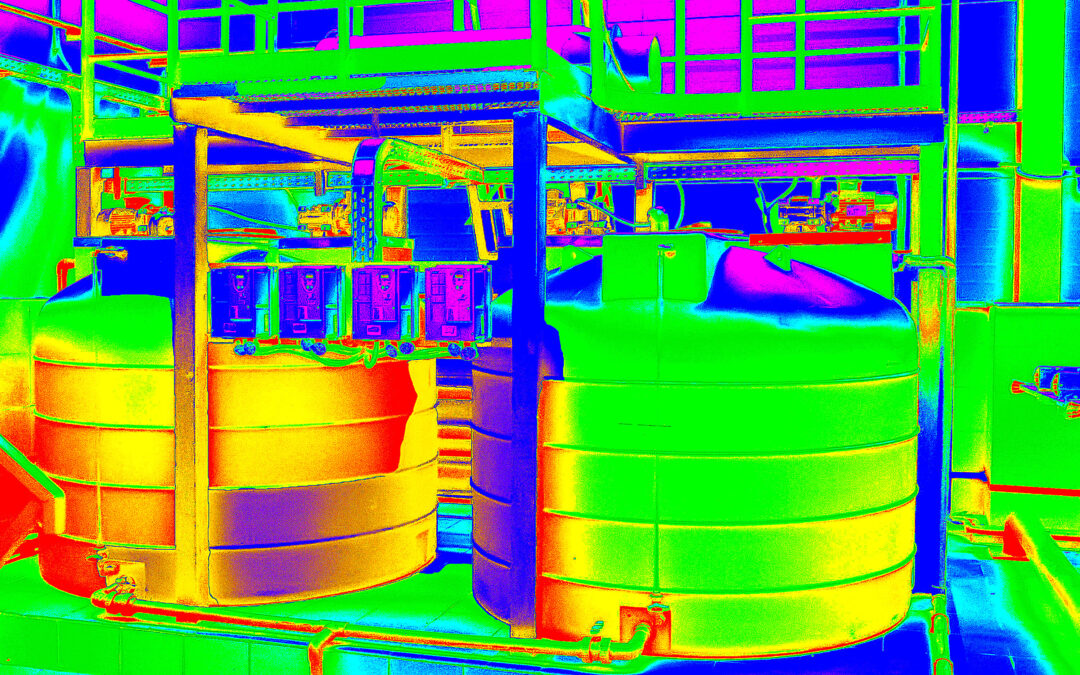

Emissivity refers to an object’s ability to radiate infrared (IR) energy. Because infrared instruments measure radiant energy, it’s imperative for a thermographer to understand Emissivity and how it can vary. All objects above 0 Kelvin radiate IR energy. The...

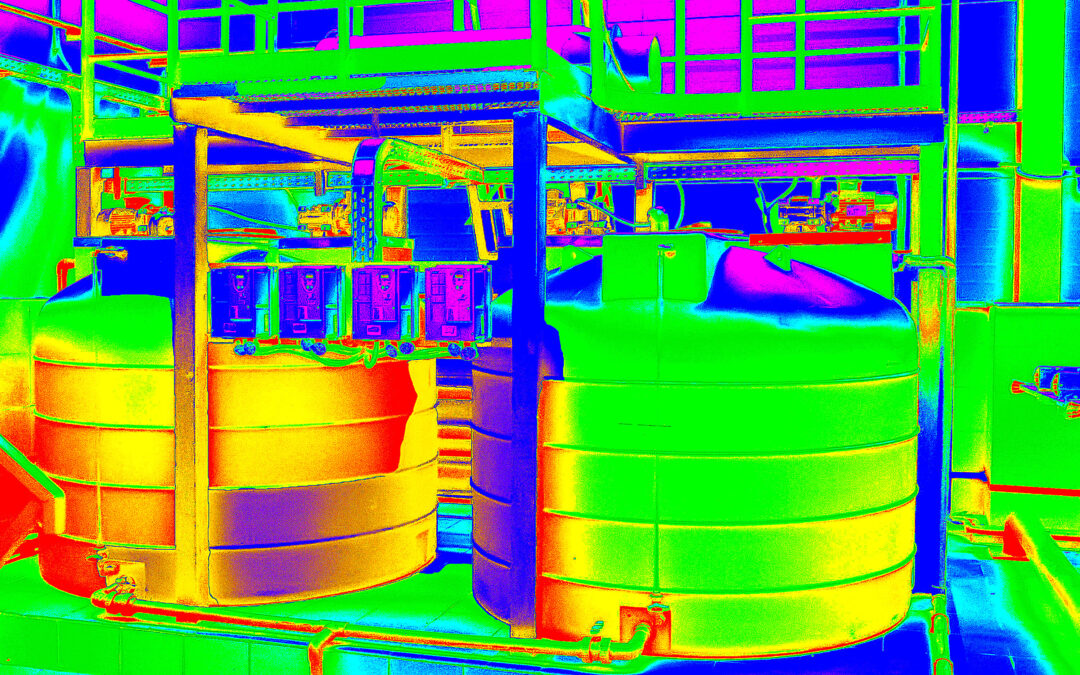

by Jim Seffrin, CMRP | Nov 21, 2021 | IR Thermography, RAM Tools & Methods

Process furnaces or heaters are critical components found in many petrochemical refineries. These large refractory-lined structures heat hydrocarbon product during the refining process. Performed properly, infrared inspections of furnace tubes can provide valuable...

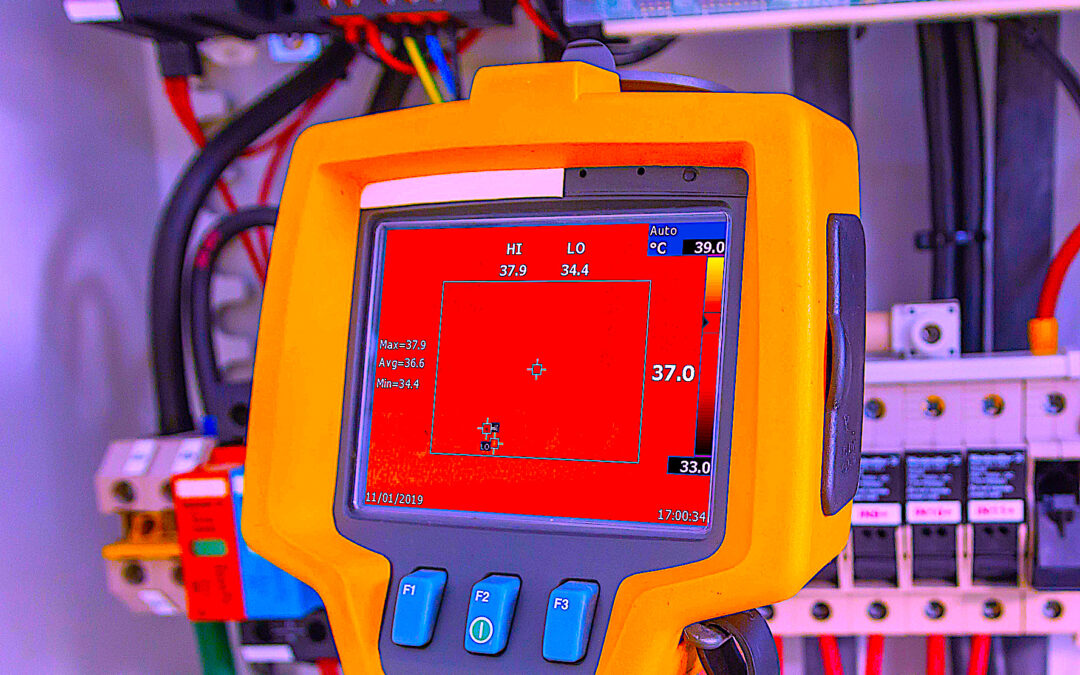

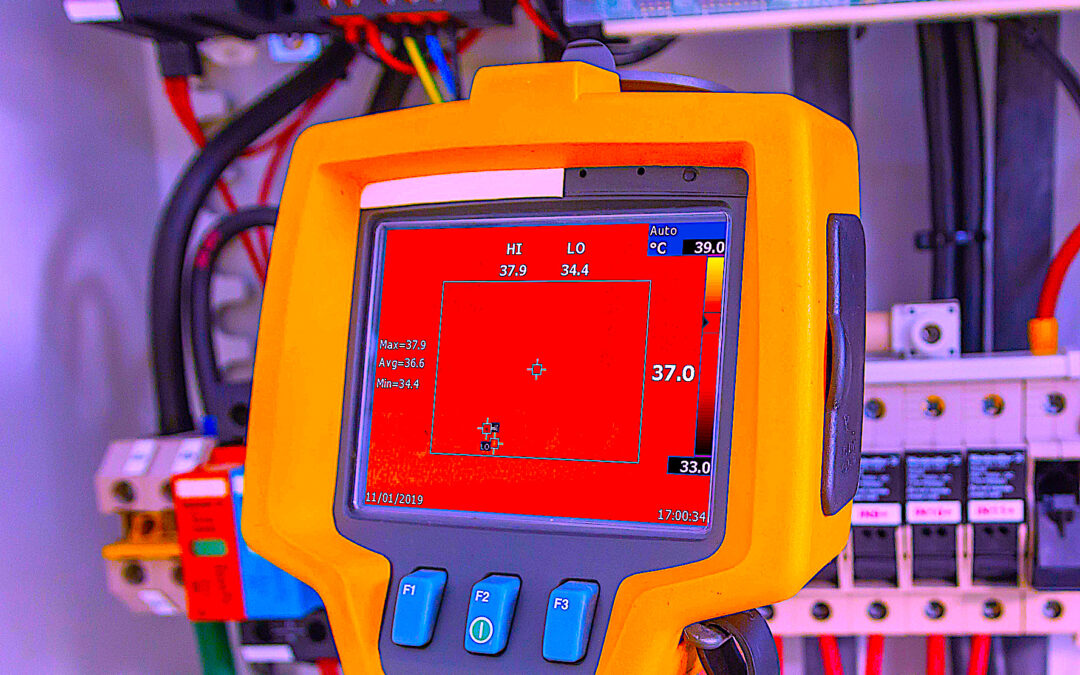

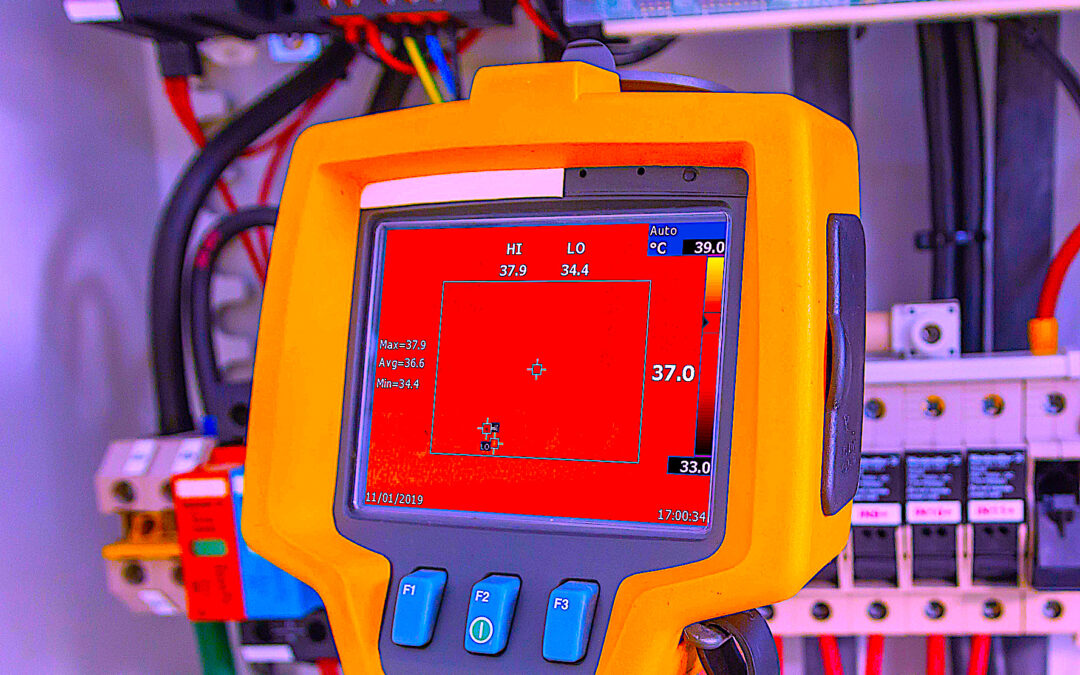

by Jim Seffrin, CMRP | Sep 5, 2021 | Electrical Reliability, IR Thermography, RAM Tools & Methods

Statistically, overloaded circuits are the second most common cause of exceptions found during infrared inspections of electrical systems. Although overloads are quite common, they can be tricky to accurately diagnose. As electrical current flows through a...

by Jim Seffrin, CMRP | May 8, 2021 | IR Thermography, RAM Tools & Methods

With tremendous emphasis placed upon the sophistication of today’s thermal imagers, it could be easy for thermographers to forget the basics of the craft. Regardless of imager age or sophistication, there are several basic concepts that can vastly increase...

by Jim Seffrin, CMRP | Mar 13, 2021 | IR Thermography, RAM Tools & Methods

Non-contact thermometry provides a means for rapidly measuring object temperatures. To ensure measurement accuracy, all error sources must be considered and properly addressed. This article discusses how to measure and compensate for Reflected Temperature using the...

by Jim Seffrin, CMRP | Feb 6, 2021 | Electrical Reliability, IR Thermography, RAM Tools & Methods

It’s a common question: “How often should electrical systems be thermographically inspected?” Historically, accepted industry practice has recommended that infrared inspections be performed annually. However, site-specific conditions may dictate considerably...

by TheRAMReview | Aug 6, 2020 | IR Thermography, SPONSORED INFORMATION

Special to The RAM Review From T/IR Systems, LLC Infrared thermography has become a popular tool for a wide range of applications. Worldwide, thermography is used on a daily basis to detect and document thermal patterns associated with defects in electrical and...

by Jim Seffrin, CMRP | May 29, 2020 | IR Thermography, RAM Tools & Methods

The more things change, the more they remain the same. This timeless observation is especially true when referring to the seemingly revolutionary image fusion feature found on some of today’s modern thermal imagers. The fusion feature found on some modern thermal...