Let’s start this particular article by looking back at a bit of history. The original concept behind Electrical Signature Analysis (ESA) is based upon the ability to perform voltage signature analysis and Motor Current Signature Analysis (MCSA), with the additional benefits of power-quality analysis using the magnetic fields between the motor rotor and stator as the transducer. Oak Ridge National Labs (ORNL) had developed the original ESA system to detect defects in motor-operated valves (MOVs) in the nuclear-power industry. During research into the detection of rotor-bar faults, the ORNL research team discovered that other electric-motor conditions, such as gears, were detectable, and that generators could be analyzed with voltage-signature analysis.

In the 1980s and 1990s, the use of ESA, sometimes mislabeled as “MCSA,” moved from the nuclear-power industry into general industrial use. Within the past few years, we have observed several additional IoT (Internet of Things) companies working toward the inclusion of both MCSA and ESA as part of their offerings.

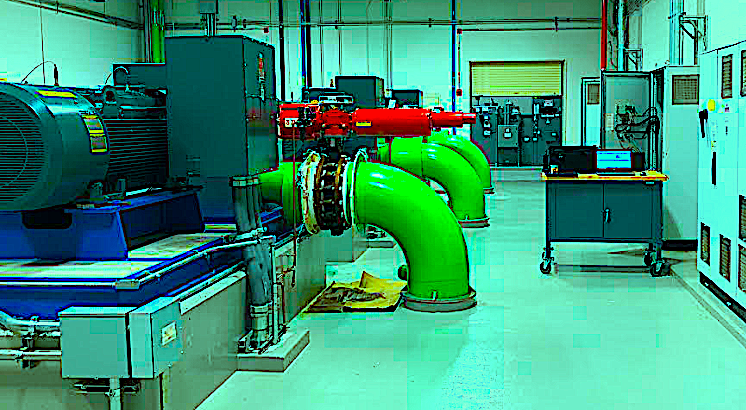

Fig. 1. Electrical Signature Analysis (ESA) testing of VFD-driven motors and pumps in a thermal-storage plant.

Fig. 1. Electrical Signature Analysis (ESA) testing of VFD-driven motors and pumps in a thermal-storage plant.

GOING FORWARD

In the next part of our ongoing electric-motor series, we’re going to focus on this technology, including how ESA works along with other technologies, such as vibration, motion amplification, and others. This week, we define the terms we will be using (and relate them to how they are used from a standards point of view versus their use in marketing efforts that we often see). For those who are using dedicated MCSA systems, you will also learn how to calculate the different faults.

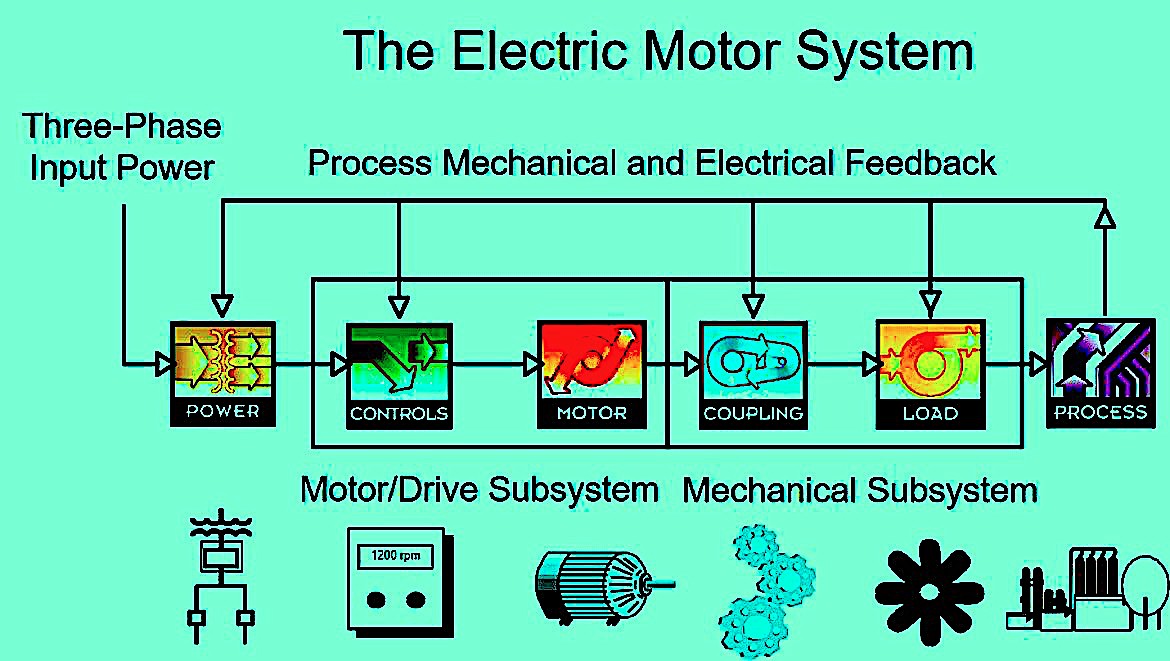

Fig. 2. An overview of typical motor-system components

Fig. 2. An overview of typical motor-system components

As noted in Fig. 2 above, the motor system is outlined as:

1. Incoming Power: For purposes of this article, we will limit the discussion to a three-phase system, although single-phase systems can be analyzed. Incoming-power-supply components include transmission lines, breakers and transformers that will provide power to a control, which may be in a motor-control center (MCC). Power supplies can be a variety of voltages from 220Vac and up.

2. Motor Controls: This part of a motor system include starters and controls of various types. This can be an across the line starter, multi-speed starter, a soft-start system, electronic soft start, variable frequency drive, amplifiers (for machine tools) and DC drives. There are other variations that may be considered.

3. Electric Motor: The transducer for ESA variations including components that can be detected with ESA technologies. The motor may be AC or DC of any type, including machine tools.

4. Coupling: This includes direct-drive, belted applications, gears, magnetic and eddy-current clutches.

5. Load: This includes all types of loads, from pumps to fans and compressors, conveyors, crushers, and other loads.

6. Process: ESA can often detect into the process itself.

ESA sees these components of an electric-motor-system ,as well as generators and powertrain.

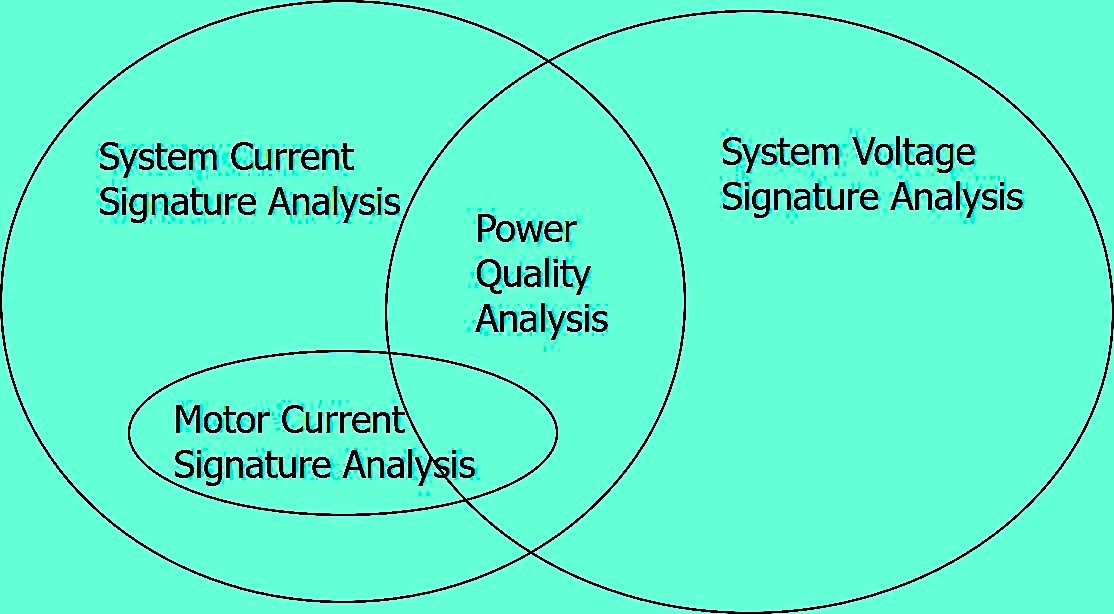

Fig. 3. The ESA Map

Fig. 3. The ESA Map

Figure 3 (above) identifies the differences between the types of analysis. The complete map, as shown, identifies the term ESA. The components are as follows:

1. Motor Current Signature Analysis (MCSA): This method includes an analysis of just the electric motor and requires the application of both current and current FFT spectrum. The presentation of FFT is often identified as decibels down (-dB) from the peak current. Capabilities include an evaluation of the rotor, stator, and bearings. There is some capability with power quality, which can provide some insight into conditions reflected from the supply that may impact motor reliability.

2. Current Signature Analysis (CSA): This method looks outside the electric motor into the coupling and driven equipment using current and current FFT spectrum as with MCSA. It requires details on the driven equipment or a comparison over time. Current looks downstream towards the load from where testing is performed.

3. Voltage Signature Analysis (VSA): This method evaluates the supply or is used to analyze generators. VSA is presented in the same way as MCSA capabilities include the ability to analyze generators, controls, transformers, and other upstream components. Another benefit is the ability to determine if a possible equipment fault is the system being analyzed when similar systems are nearby. For instance, if a rotor dynamic eccentricity signature appears in MCSA, it can be compared to see if higher peaks exist in VSA vs MCSA. If the peak is higher in VSA, then the condition resides outside of the electric motor system.

4. Power Quality: Combined voltage and current data provides the ability to analyze power quality issues that can be addressed. Power quality can occasionally drive equipment failures or may identify underlying additional issues.

COMING UP

Power quality and, on occasion, limited MCSA have been used by some marketers to misrepresent as ESA. Keep in mind, though, that the definition of ESA involves the full ability of voltage and current analysis, including FFT spectra, not just whether the current is balanced in a system or harmonics exist. Often, marketing material will exaggerate the impact of power quality on machine reliability. Power-quality analysis was covered earlier in this series on electric machines (refer to article links below). In the next article in the series, we will focus on spectral analysis of ESA.TRR

Click On The Following Links for Previous Articles In This Electric-Motor Reliability Series

March 28, 2020: “What The Studies Really Said”

April 12, 2020: “Comparing What The Studies Said”

April 18, 2020: “How The Studies Applied to Larger Motors”

May 2, 2020: “A Data Mind-Bender”

May 29, 2020: “Site and Study Findings Compared”

June 13, 2020: “Developing Testing Programs”

June 19, 2020, “High-Voltage Testing”

July 3, 2020: “Testing with Ohm Meters”

July 10, 2020: “Best Practice to Insulation to Ground Testing Methods”

July 25, 2020: “Annex D in IEEE 43-2013

August 7, 2002: “Advanced Insulation Systems & Hi-Pot Testing”

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: motors, drives, motor testing, Electrical Signature Analysis, ESA,, reliability, availability, maintenance, RAM