Reliability & Maintenance Opportunities: (Part 2) Belted Equipment

A plant’s electric motors and driven equipment are good places to look when seeking to reduce energy costs and greenhouse-gas emissions. Their belts have a big impact on both of those goals.

Skills-Training Quick Start

The critical, often overlooked step after training is formal “qualification” to perform the tasks learned in training. Qualification is, in effect, the opportunity to demonstrate crucial task proficiency.

Opportunity Preparedness

The ultimate objective of Maintenance and Production departments is to eliminate avoidable uncontrolled and controlled internal shutdown events. Opportunity-based maintenance can help get it done.

Change Management From The Middle Out

Most organizations suffer from some degree of psychological inertia. Breaking through it is key to successful transformational change. But top-down and bottom-up management approaches may not work.

Regarding Those Field Erection And Installation Specifications For Special Purpose Machinery

Owner/Operators would be foolish not to give utmost attention to specs that reflect reliability and uptime goals. That notion might clash with how some design and construction projects are awarded.

Reliability & Maintenance Opportunities: (Part I) Compressed Air System Efficiency

Compressed-air systems are the lifeblood of many types of production systems. The use of compressed air, however, comes with significant energy costs, even in a well-maintained system.

The Power Of Relationships

In an industrial environment, no department is an island unto itself. For maintenance departments, building strong relationships with other plant functions is key to continuous improvements.

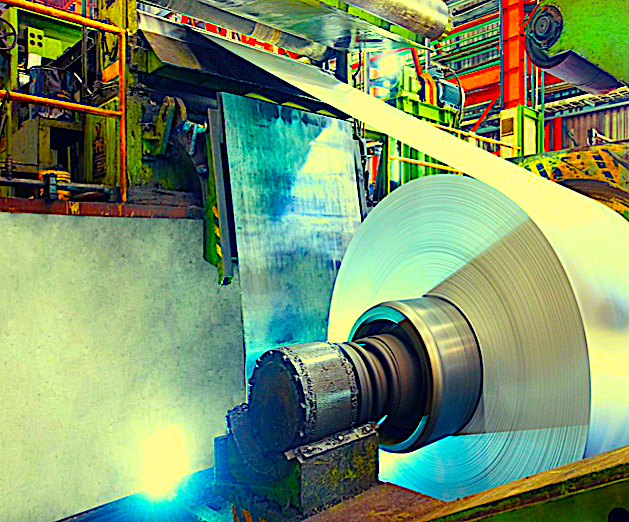

Optimizing Performance Of Cold Rolling Mills

New ABB Ability service offering is said to unlock greater levels of productivity, quality, and yield.

Precision Maintenance Requires Precision Parts: (Part II) Rebuild For Reliability

Sites rely on countless rebuilt parts and components to deliver process reliability. Unfortunately, it’s rare to find plant personnel adhering to best practices that lead to the best rebuilds possible.

Update Your Grease Compatibility Know How

Staying abreast of grease technology is a given for reliability and maintenance pros. Doing so goes beyond consulting compatibility charts. FYI: Charts in some of today’s plants may not reflect current technology.