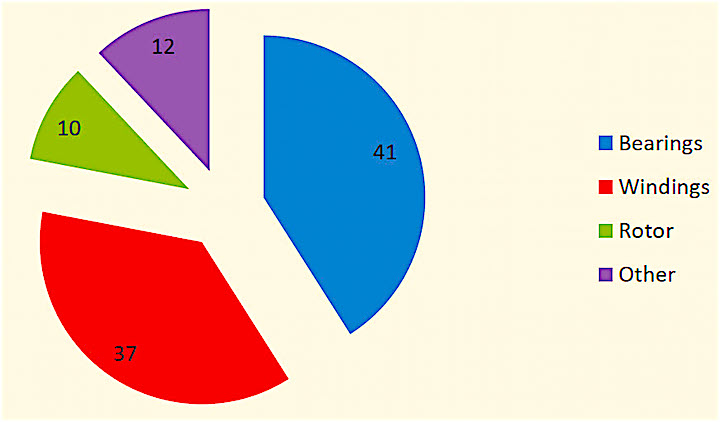

The graph in Fig. 1 below is often quoted as showing the average failure rates in a population of electric motors throughout industry, and cited as the results of a 1983 Electric Power Research Institute (EPRI) study. This General Electric study of large power-plant motors has been used to support a variety of programs, equipment, and other electric motor strategies. The challenge was that the paper and data had not been available and the original results have not been published.

The studies were part of a series of Institute of Electrical and Electronics Engineers (IEEE) projects used to update the IEEE Std 493, “Gold Book: IEEE Recommended Practice for the Design of Reliable Industrial and Commercial Power Systems,” and, IEEE Std 3006.8, “Recommended Practice for Analyzing Reliability Data for Equipment Used in Industrial and Commercial Power Systems.” These studies occurred in 1955, 1965, 1975, 1985, and, 1995, with the 1983 EPRI project running parallel with the 1985 IEEE project (and involving most of the same engineers).

The 1983 EPRI project focused on medium- and high-voltage power-plant motors, while 1985 IEEE project focused on commercial/industrial motors. Each of these studies involved different commercial and industrial sectors and motor sizes, with the 1995 research concluding with metric motors under 600 volts for offshore platforms.

Fig. 1. 1983 EPRI study failure rates (%)

In addition to the IEEE and EPRI studies, EASA performed a study on motor repairs in 2010. What is particularly interesting about these studies is that they focus on different industries, such as petrochemical, utilities, general industry, and commercial buildings, yet have very similar results. While each study looked deeper into the issues, and the results were different than represented by many papers and books, the actual findings were much more interesting and far more supportive of the programs and strategies presented in those cases.

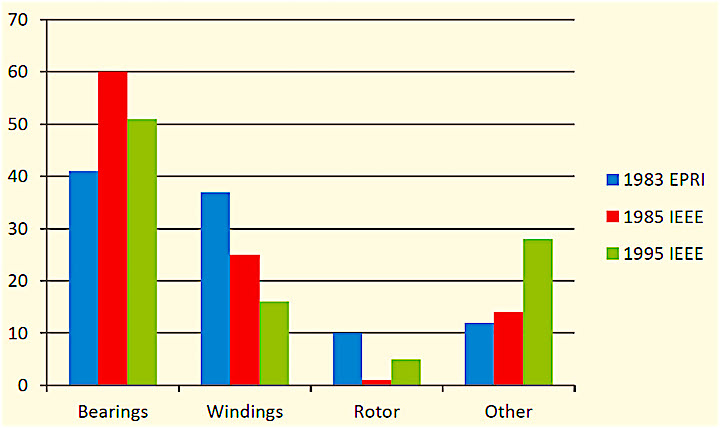

Fig. 2. Comparison of the 1983 EPRI study and the 1985 and 1995 IEEE studies

As shown in Fig. 2, although the actual failure modes for each industry group were similar, they had significantly different rates based upon their size and application. A majority of faults still show as bearings, then windings, then rotor and all other faults combined. A marked difference between the 1983 EPRI study and the 1985 IEEE survey, though, is that the latter (IEEE’s research) covered machines from 200 hp to 10,000 hp; voltages to 13.8 kv; and induction, synchronous, wound-rotor, and DC motors. There is also the difference between smaller ball- and roller-bearing motors and larger sleeve-bearing motors.

Going forward in this series, we will be reviewing large motors, then smaller ones, and discussing what these studies really represent. We will also cover reliability issues that were identified and the recommended strategies.TRR

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: motors, drives, voltage, power systems, reliability, availability, maintenance, RAM, EPRI, IEEE, EASA