What did the 1983 EPRI study and subsequent IEEE studies of large electric motors really say? With the EPRI study primarily identified as one on motor failures, the focus of this article is related to how the reported findings iof that research compare to those of the other reliability-related studies.

The percentages shown in my Mar. 28, 2020, article for this series (see link below) have often been cited as the conclusion from the EPRI study. That’s somewhat correct. However, the details behind those percentages are also very interesting. This includes the number of motors that failed more than once and the apparent causes of those failures, as well as the general reliability of electric motors in power utilities, as the 1983 study was on power generation.

More than 90% of the failures occurred in 54% of the facilities evaluated and half of the failures occurred in 17% of the facilities. Overall, the reliability of the motors across all of the facilities was 0.034 failures per motor per year (FPU – Failures Per Unit Year, failure rate) with some facilities having an obviously higher failure rate and 46% having a very low failure rate. The study found that the 17% of plants with the higher failures had a failure rate of and average of 0.093 FPU and that 13% of facilities had an average of 0.008% FPU.

There were 4,797 motors evaluated in the EPRI study with a total of 1,227 primary failures on 872 motors. This means that 335 of the 1,227 failures were repeat failures. The best facilities saw some of the motors fail two to three times. The median group saw motors fail four or more times, and the worst-case group saw an even higher repeat failure rate.

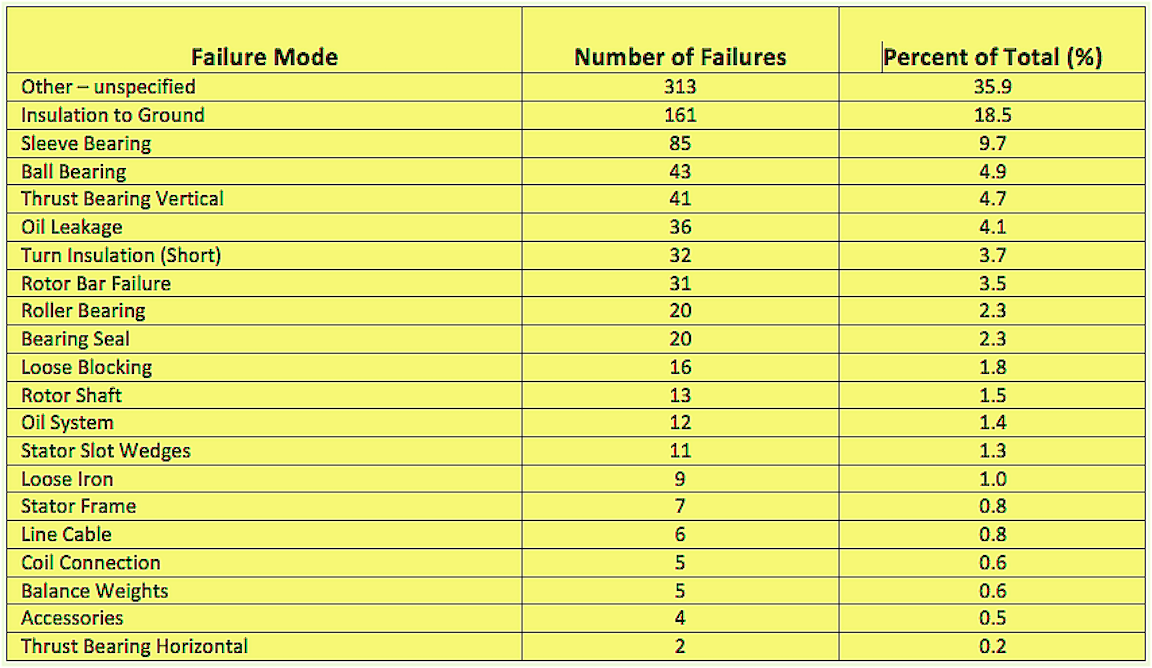

The apparent causes of failure were also surprising with only 34.1% of failures being from mis-application or mis-operation. It was noted that 50.2% of the failures were not specified with an apparent cause and the repeat failure modes were identified with repeated failures being the same as the original failures. Table I (below) identifies the failures and the percent of each failure mode.

Of these failures, design was determined to be 39.1% and workmanship was 26.8% ,resulting in the EPRI study finding 65.9% of the motor failures were related to the manufacturer and rebuilder.

The failure rate by manufacturer was found to range from 0.84% to 5.27% for the top seven manufacturers, 16.44% for the least reliable manufacturer, and a combined total of 6.5% for all other manufacturers. The manufacturers were not identified by name.

Table I: Failure Modes

Motor failure studies in the 1980s determined that a given population of motors had either an average failure rate of 0.0708 FPU for general industry, per the 1985 IEEE study, or 0.035 for maintenance intensive industries such as utilities, as identified in the 1983 EPRI study. In 1995, new studies would support the original assumptions. The industry studies found that in machines with required minimum protection, such as fuses or breakers, the failure rate was 0.0707 FPU, while those with embedded thermal protection had a failure rate of 0.0202 FPU, or less than 1/3 of the failures.

Maintenance activities were found to have a significant impact through all of the studies. When maintenance frequency was involved, the post-EPRI studies all found that frequencies of less than a year had the greatest impact. The 1985 IEEE study identified that maintenance performed with a frequency under 12 months equaled 0.0124 FPU; from 13-24 months had 0.0506 FPU; and, maintenance frequency of greater than 25 months resulted in 0.0881 FPU.

A key difference between the EPRI and IEEE studies is that the 1985 IEEE study reviewed not just the general failures, but also broke out service factor, speed and maintenance. The 1995 IEEE study further modified the findings by identifying size and voltage in order to determine factors that relate to each. In 2010, a paper on root cause failure analysis of motors supported the findings of the 1995 study.

One consideration for these studies is their ages: do the results change over time and motor newer designs? From the 1974 IEEE study relating to electrical reliability of electrical equipment in industrial plants through the 1995 IEEE study, fundamental facts and rates have not significantly changed based upon application, enclosure, service factor, speed, protection, and level and type of maintenance. The combined studies cover virtually all industries from petro-chem to utilities and commercial to industrial applications.TRR

BIBLIOGRAPHY

1. Albrecht, et.al, “Assessment of the Reliability of Motors in Utility Applications,” IEEE Transactions on Energy Conversion, Vol. EC-2, No. 3, September 1987

2. Albrecht, et.al., “Assessment of the Reliability of Motors in Utility Applications – Updated,” IEEE Transactions on Energy Conversion, Vol. EC-1, No. 1, March 1986

3. “Report of Large Motor Reliability Survey of Industrial and Commercial Installations, Part 1,” IEEE Transactions on Industry Applications, Vol. IA-21, No. 4, July/August 1985

4. “Report of Large Motor Reliability Survey of Industrial and Commercial Installations, Part 2,” IEEE Transactions on Industry Applications, Vol. IA-21, No. 4, July/August 1985

5. “Report of Large Motor Reliability Survey of Industrial and Commercial Installations, Part 3,” IEEE Transactions on Industry Applications, Vol. IA-23, No. 1, January/February 1987

6. Thorson and Dalva, “A Survey of Faults on Induction Motors in Offshore Oil Industry, Petrochemical Industry, Gas Terminals, and Oil Refineries,” IEEE Transactions on Industry Applications, Vol. 31, No. 5, September/October 1995

7. Bonnett, Austin H., “Root Cause Failure Analysis for AC Induction Motors in the Petroleum and Chemical Industry,” Proceedings, 57th Annual Petroleum and Chemical Industry Conference, 2010

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: motors, drives,, electrical systems, power gneration, reliability, availabitlity, maintenance, RAM