This week’s article on Overall Materials Effectiveness (OME) concludes our seven-part series on leading metrics that drive proactive behaviors for maintenance and reliability. Along with Overall Planning Effectiveness (OPE), and Overall Scheduling Effectiveness (OSE), Overall Materials Effectiveness drives down the lagging metric Mean Time to Repair (MTTR).

For purposes of this OME discussion, we’re focusing on the degree to which our materials management practices support effective maintenance in the plant. Metrics that reflect general supply-chain and warehouse management practices are important, but beyond the scope of leading metrics that drive MTTR performance.

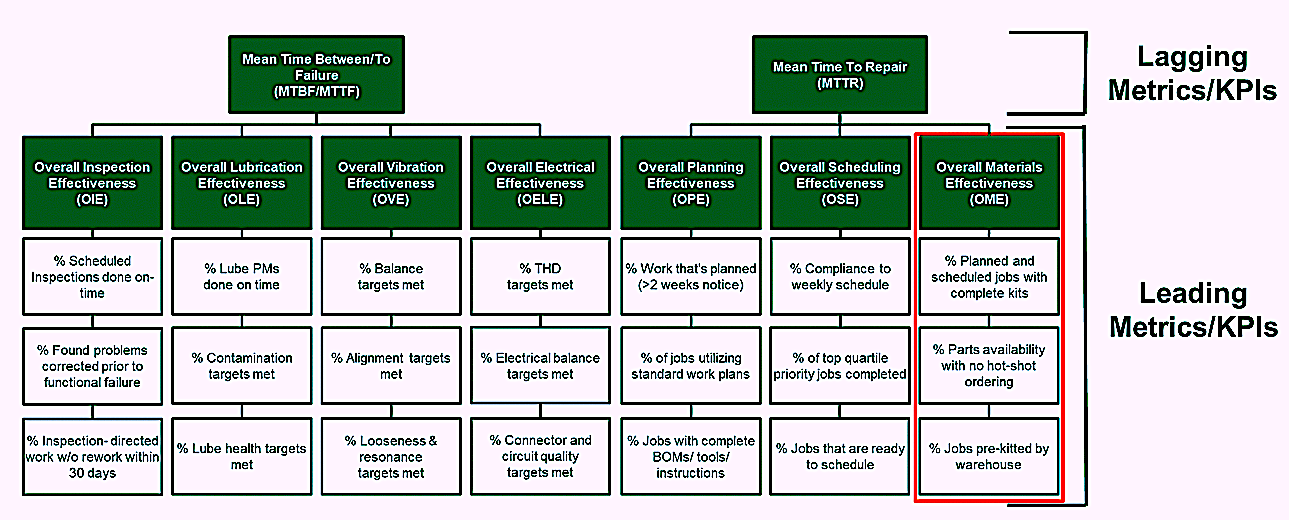

Fig. 1. Overall Materials Effectiveness (OSE) is a leading indicator

Fig. 1. Overall Materials Effectiveness (OSE) is a leading indicator

that drives proactive behaviors, which, in turn drive asset reliability.

WHAT OME IS AND WHY IT’S IMPORTANT

Once a maintenance job has been successfully planned and schedule, it must be successfully executed. Successful execution of a maintenance jobs requires completion of all prework and permitting, a definition of the required tools to complete the job, clear work instructions and the right parts and materials that are required to complete the job staged at the right place at the right time. It should be noted that the parts must also be in the right condition, but that’s a function of warehouse management practices, which we’ll explore in a future issue of The RAM Review.

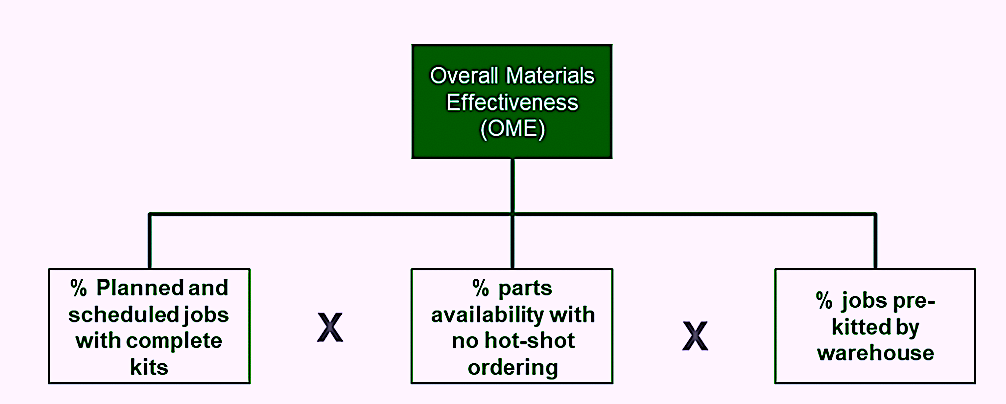

OME is calculated as the product of multiplying the following three input factors (Fig. 2):

1. Percentage of planned and scheduled jobs with complete kits.

2. Percentage parts availability with not “hot-shot” (expedited) ordering.

3. Percentage of jobs pre-kitted by the warehouse.

Fig. 2. The simple formula for OME, which is the product of multiplying

Fig. 2. The simple formula for OME, which is the product of multiplying

the ‘behavioral inventories’ for the three input factors.

When one performs “Day In the Life of” (DILO) studies to determine what prevents crews from efficiently and effectively executing maintenance work, materials unavailability often rises to the top of the hurdles list. In other words, a maintenance job simply cannot or could not be completed with the available parts and materials. When required parts and materials are unavailable, maintenance craftspeople and their supervisors must either dismiss the job or get busy chasing down the needed items. That often goes as far as phoning suppliers and orchestrating heroic logistics if the maintenance work is deemed critical or important. In worse-case scenarios, the lack of proper parts and materials forces maintenance crews to make do with substitute parts or scavenge the junkyard of failed machines to extract used components or parts. Both scenarios set the stage for the next failure. But it gets worse.

Consider, for example, if substitute components are used and the organization doesn’t have well-defined bills of materials (BOMs) for its work plans and/or employs a “like for like” parts-exchange methodology for executing repairs. Going forward, the same wrong part could be installed every time the asset requires maintenance and short component life becomes culturally accepted as normal.

As is the case with other leading metrics, we must view the OME elements as an inventory process of binary observations: The job complies, or it doesn’t. Each element of the OME metric is displayed as a percentage of the complying observations divided by the total number of observations and converted to a percentage. The OME is the product of multiplying the three components together. If OME increases, we’re practicing behaviors that will drive MTTR down, which is our goal. Let’s explore the three components of OME in more detail.

1. Percent Planned and Scheduled Jobs with Complete Kits

Nothing kills wrench/spanner time performance more than forcing the crews into a parts-chasing mode. As was discussed in the Overall Scheduling Effectiveness (OSE) metric, a job isn’t ready to schedule until the following criteria are met.

- All required parts and materials identified in the bill of material (BOM) must be verified to be on-hand.

- Any special tools required to complete the job, including any outside tools hire, are available.

- Any scaffolding or other required pre-work has been completed or will be completed, prior to the

commencement of job completion. - Access to the equipment has been approved, permitted, and coordinated with operations as required.

- Job plans and work instructions are complete and wrench/spanner-ready, including the following:

Having all required parts and materials on hand is right at the top of the list of the items necessary to declare a job “ready to schedule.” If the maintenance scheduler is informed by the warehouse that this requirement has been met when it is, in fact, not, the case, the maintenance crew is forced to dismiss the job or go into a reactive mode to find parts. When this happens, the best-case scenario is wasted time. What was to have been a two-person, two-hour job winds up taking all day or gets pushed to another day. In the worst case, the crews have to force-fit parts or scavenge used parts to complete the job, which puts the equipment’s reliability at risk. Having a complete parts kit is imperative to ensure efficiency and effectiveness of maintenance work execution.

2. Percentage of Parts Availability with No ‘Hot-Shot’ (Expedited) Ordering

Expediting parts to complete a job is expensive. Suppliers often demand a premium to bump other customers and move you to the front of the queue. The cost, however, is just the tip of the iceberg. The requirement to expedite parts is not only a wrench/spanner time killer, it also can demand massive amounts of time and effort from supervisors, maintenance managers, engineers, and, of course, warehouse personnel. When maintenance jobs frequently require expedited, i.e., hot-shot, parts ordering, it’s an indictment of the entire inspect-to-execute maintenance process.

Unless a maintenance job is time/distance/cycles-based, wherein assuring parts on-hand without hot-shot orders should be a breeze, the maintenance process starts with an inspection. When the inspection reveals that maintenance work is required, a notification is generated. Notifications go through a gate-keeping process, whereby they are denied or approved and, if approved, prioritized. Jobs that are approved and prioritized then enter the planning stage. Once planned, they’re scheduled and executed. Lots can go wrong in that serial process, though.

If the notification isn’t adequately clear, it’s possible that the job won’t be properly approved and prioritized. Or, during the planning process, the job may be incorrectly scoped and not identify the parts and materials required for completion. Or the process for verifying that the required parts and materials are on hand before declaring the job “ready to schedule” could fail. Moreover, the warehouse inventory system might erroneously confirm that the parts are on hand when, in fact, they are not. Any errors in the serial inspect-to-execute maintenance process can produce an expedited-parts-procurement scenario. Watch your hot-shot-job-percentage performance very closely: It’s a powerful leading metric that reveals flaws in the entire maintenance process. Focusing on behaviors that reduce or eliminate the need for expedited parts orders delivers a substantial value to the organization.

3. Percentage of Jobs Pre-kitted by The Warehouse

In an ideal situation, parts and materials will be pre-kitted by the warehouse for easy and convenient pick-up by the maintenance crews. This is straight-up division of labor to improve efficiency. If a job is properly planned, there’s no reason why it can’t be pre-kitted by the warehouse. Maintenance crews cooling their heels at a warehouse counter as they wait for a clerk kills wrench/spanner time (and usually captures the ire of plant managers if they see it). Ideally, the parts and materials required to complete jobs are kitted AND staged. This sensible division of labor makes everyone more productive and allows the organization to get more high-quality maintenance work completed with the crew hours for which it is paying.

IN CONCLUSION

Maintenance work can’t be effectively and efficiently executed without the right parts, at the right place, at the right time. Chasing parts is a primary wrench/spanner time performance killer as maintenance crews and their supervisors hunt for whatever is needed to complete a scheduled job. Resorting to the use of substitute parts that “will fit and do in a pinch” or those scavenged from the junk pile sets the stage for the next failure and compromises reliability.

Take dead aim at Overall Materials Effectiveness (OME) to 1) ensure that you have complete parts and materials kits for scheduled jobs; 2) ensure that jobs requiring hot-shot or expedited parts are minimized; and 3) ensure that your warehouse personnel are pre-kitting and staging materials to improve overall crew productivity. In short, target leading indicators that drive behaviors to assure jobs are planned and scheduled properly and materials are managed effectively. Then watch your operations’ Mean Time to Repair (MTTR) performance drastically improve.

This concludes our seven-part series on proactive leading metrics that drive improved Mean Time Between/To Failure (MTBF/MTTF) and reduced Mean Time to Repair (MTTR). To read previous installments, see the links below. Going forward, I’ll follow up in more detail on several issues that were raised in these articles, as well as delve into lagging metrics to make clear connections between them and the leading metrics discussed in this series.TRR

Click Here To Read Previous Articles In This Series On Leading Indicators For Asset Management

“Overall Inspection Effectiveness (OIE)”

“Overall Lubrication Effectiveness (OLE”)

“Overall Vibration Effectiveness (OVE)”

“Overall Electrical Effectiveness (OELE)”

“Overall Planning Effectiveness (OPE)”

“Overall Scheduling Effectiveness (OSE)”

ABOUT THE AUTHOR

Drew Troyer has over 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 300 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees. Drew, who also earned a Master’s degree in Environmental Sustainability from Harvard University, is very passionate about sustainable manufacturing. Contact him at 512-800-6031, or email dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, metrics, key performance indicators, KPIs, planned maintenance, work work plans, wrench time, spanner time, spare parts, replacement parts, Overall Materials Effectiveness