by Heinz Bloch, P.E., Editor | Nov 27, 2021 | Lubrication Corner, Tech Reviews, The Bloch Files

It has long been proven that soundly executed long-term storage protection of sensitive machinery, such as compressors and drivers, will save much money. The same holds true, of course, for general purpose machines, the bulk of these being process pumps, electric...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 24, 2021 | Asset Management, Lubrication Corner

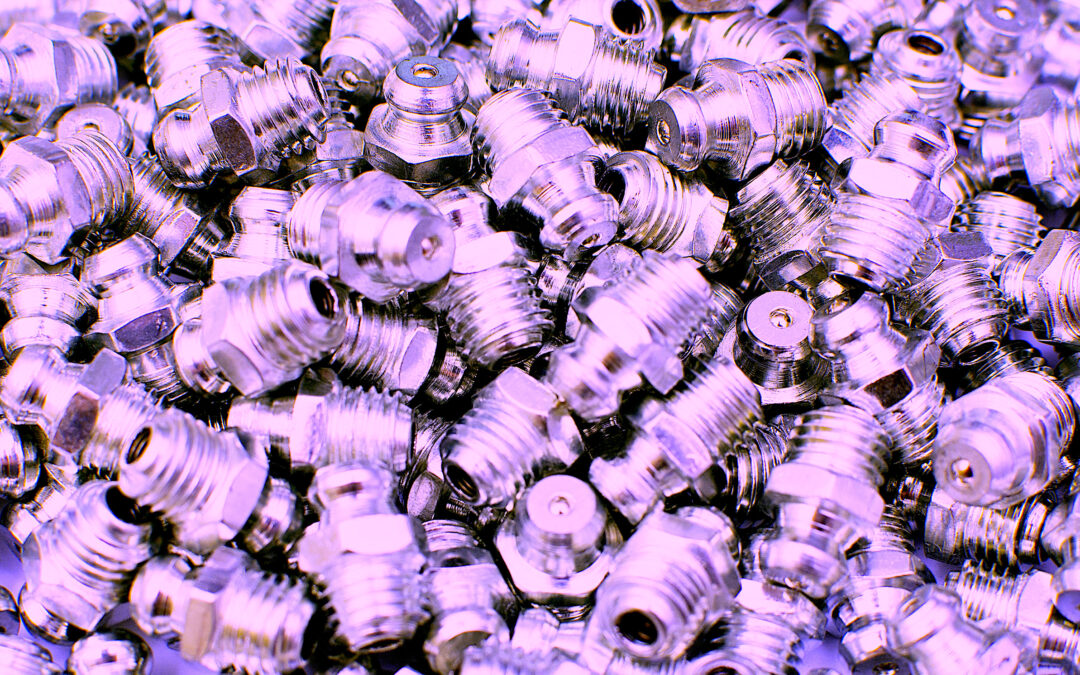

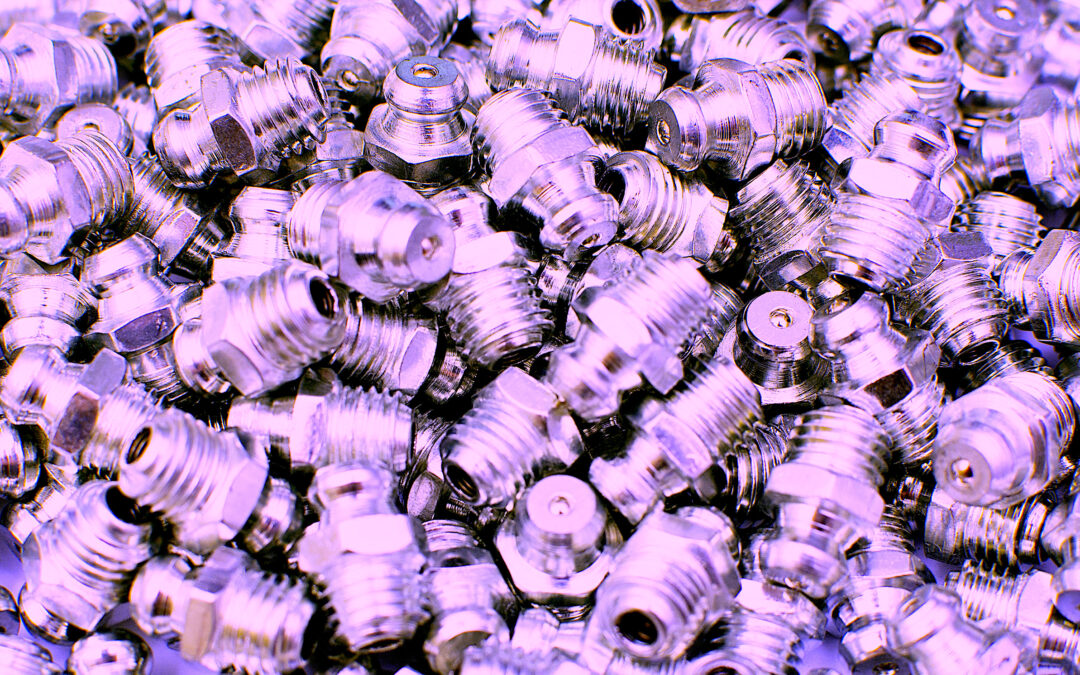

The lowliest and most ubiquitous device in the world of lubrication recently celebrated its centennial anniversary. Designed as a simple, yet efficient mechanical gateway device, the grease nipple has only one job: to connect to a manual grease-delivery gun and...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Aug 30, 2021 | Asset Management, Lubrication Corner

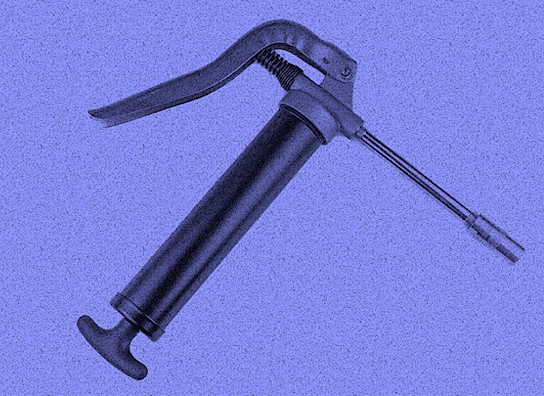

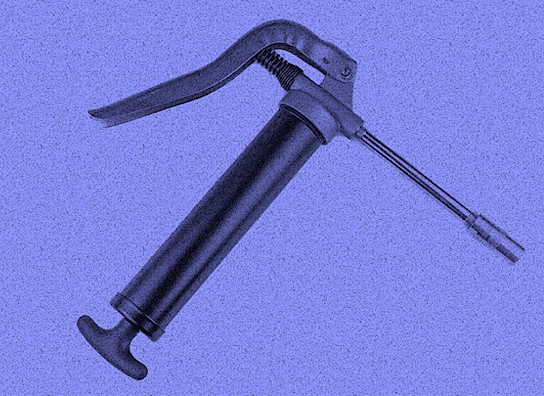

Grease guns seem simple enough. But how well do you know yours? Do you know how to correctly cartridge and/or bulk load your gun? Do you know how to expel trapped air from it? Do you know its shot size in cc or cu in (e.g., in cubic centimeters or cubic inches)? Do...

by Heinz Bloch, P.E., Editor | Aug 8, 2021 | Learning from Mistakes, Lubrication Corner, The Bloch Files

The subject of lubrication is rarely, if ever, taught in U.S. universities. That’s regrettable. Misunderstandings and lube-related errors abound in plant operations and cost industry millions of dollars each year. The following collection of real-world case...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 11, 2021 | Asset Management, Lubrication Corner

The online resource Dictionary.com defines the word “clean” as “free from dirt,” “free from foreign and extraneous matter.” To most, “clean” is a subjective term, the interpretation of which depends on the subject matter and the interpreter’s standards for...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jun 19, 2021 | Asset Management, Lubrication Corner

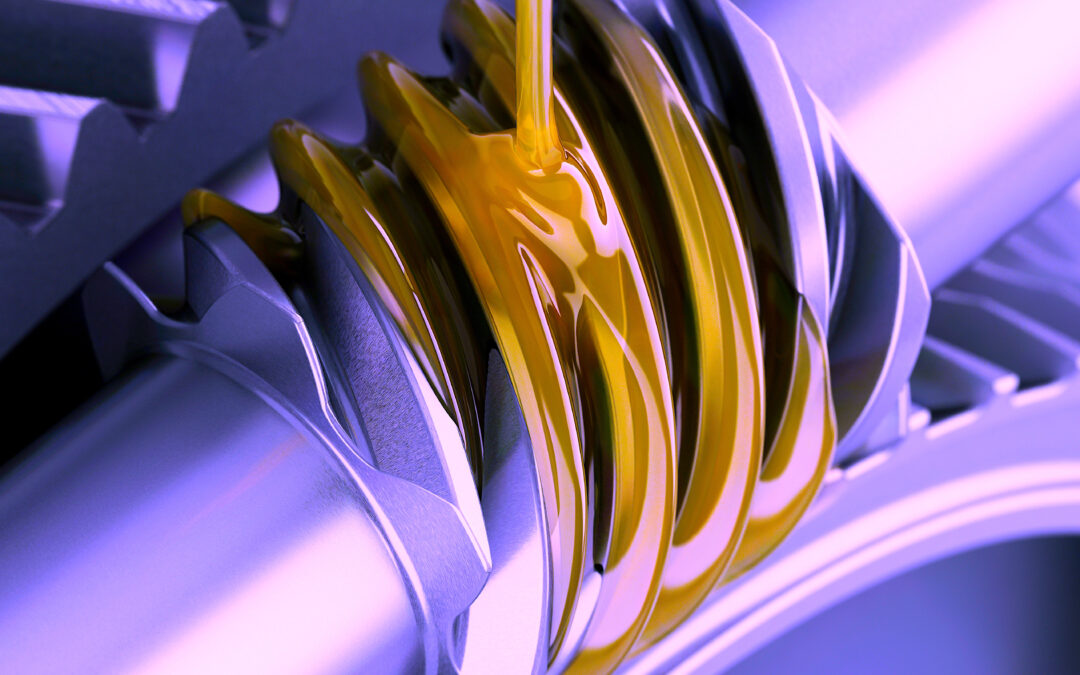

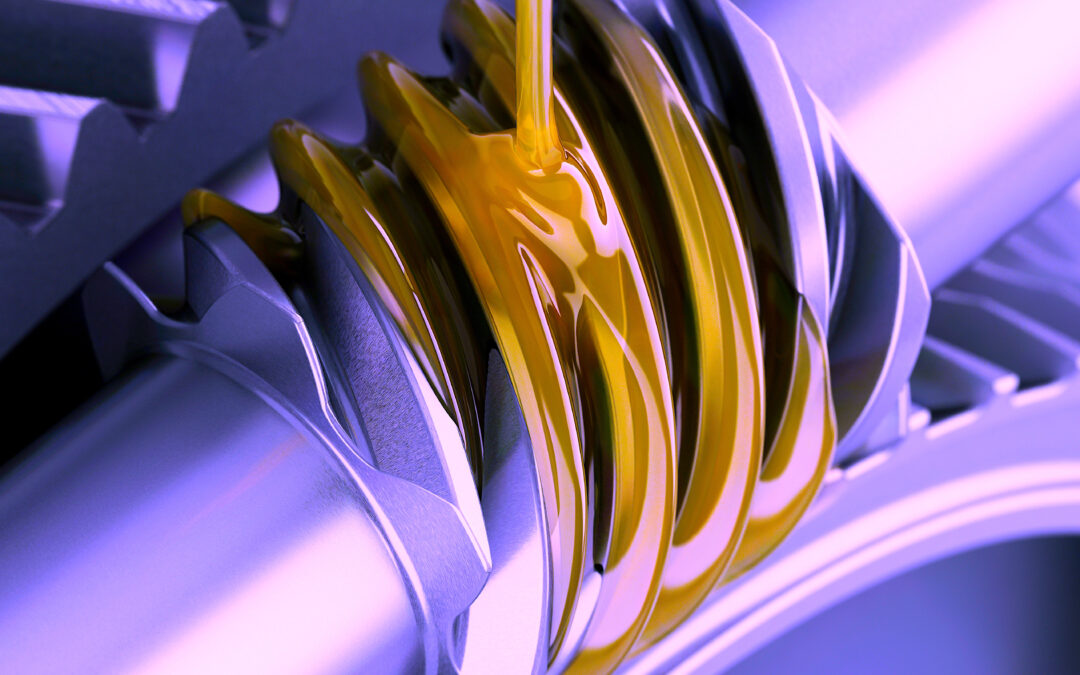

I was recently asked, “Why are lubricants so different? Why can’t we simply buy a ‘one fits all’ oil and grease?” I explained that the old farmers axiom, “Oil is oil, any oil will do,” may have had some merit 100 years ago, but it doesn’t now. In...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jun 6, 2021 | Asset Management, Lubrication Corner

If a machine is to provide service life past its warranty stage, its designer must envision and consider all operating conditions under which the machine will operate in the field. For example, to mitigate the effects of severe and semi-severe conditions, the design...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | May 1, 2021 | Asset Management, Lubrication Corner

When a lubricant manufacturer decides to update or develop a new lubricant for market, it begins by developing a lubricant specification. Built around a series of industry-defined parameters, performance standards and tests, this specification becomes a lubricant’s...

by Heinz Bloch, P.E., Editor | Mar 27, 2021 | Lubrication Corner, RAM Tools & Methods, The Bloch Files

Every so often, it’s time to ask if our knowledge of a reliability subject is up to date. The need to stay abreast of grease technology is a case in point: One case study showing the benefits of doing so dates back to around 2006. That’s when a Texas-based...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Mar 21, 2021 | Asset Management, Lubrication Corner

When it comes to fleet and generator maintenance, nothing has a bigger impact on engine-life cycle than a simple oil and filter change. Yet, as straightforward as an oil change sounds, effectiveness is only assured by using the correct lubricant viscosity. If you own,...