by Randall Noon, P.E. | Jan 15, 2022 | Learning from Mistakes, Plant Operations, RAM Tools & Methods

Minimizing vibrations in rotating equipment increases equipment service life. Some of the benefits of lower vibration levels include reduced transient loads, lower bearing temperatures, and reduced wear. In that regard, most engineers, mechanics, and technicians are...

by Randall Noon, P.E. | Aug 21, 2021 | Learning from Mistakes, Plant Operations

Author’s Note: As with a number of my past articles for The RAM Review, this one also is an amalgam of several similar event investigations. Any details that would otherwise allow a specific company or person to be identified have been generalized, combined, or...

by Heinz Bloch, P.E., Editor | Aug 8, 2021 | Learning from Mistakes, Lubrication Corner, The Bloch Files

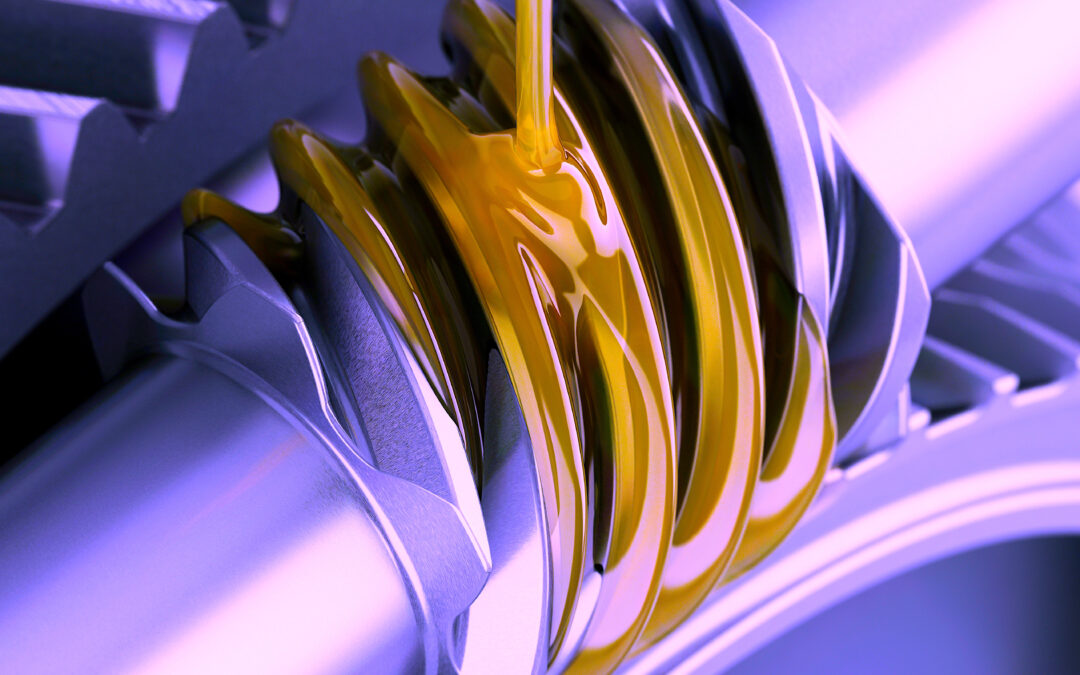

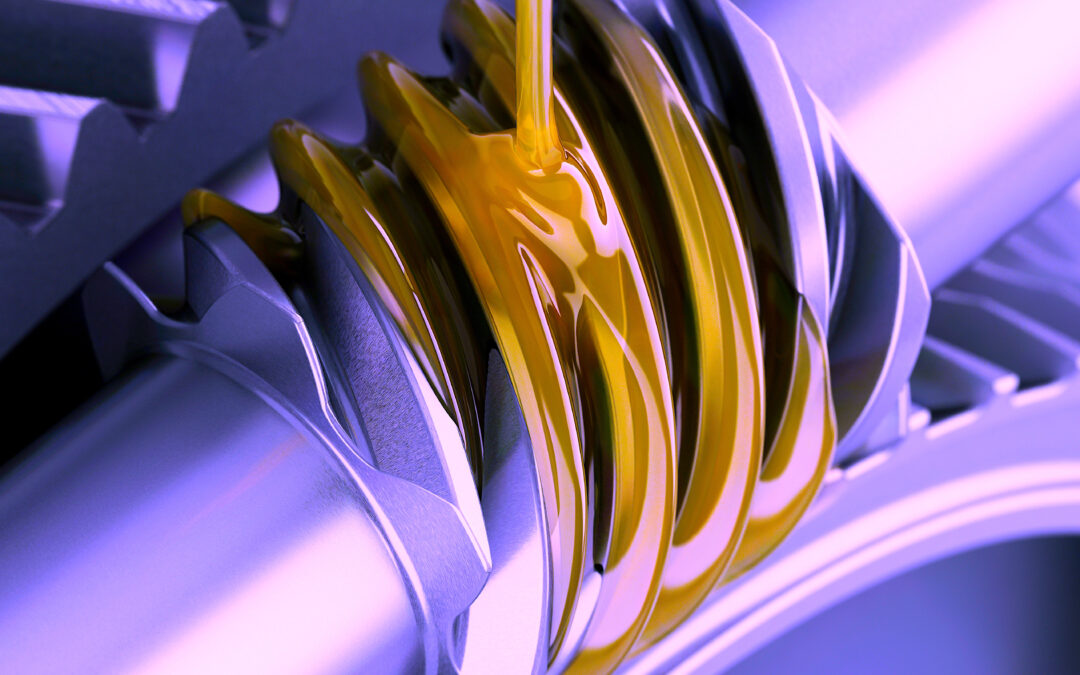

The subject of lubrication is rarely, if ever, taught in U.S. universities. That’s regrettable. Misunderstandings and lube-related errors abound in plant operations and cost industry millions of dollars each year. The following collection of real-world case...

by Randall Noon, P.E. | Apr 22, 2021 | Asset Management, Learning from Mistakes

Today’s root-cause methodologies often employ the following failure-investigation process. It’s straightforward and practical. And the failure-cause spreadsheet that results from the process will provide a convenient record-keeping document to use in...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Mar 27, 2021 | Learning from Mistakes, Plant Operations

As organizations wrestle with a huge variety of COVID-19 impacts, they’re often running short-handed and without a full complement of support services. They may also be experiencing unpredictable supply-chain interruptions (upstream from their suppliers and...

by Randall Noon, P.E. | Dec 5, 2020 | Learning from Mistakes, RAM's Human Factor, Safety Matters

The following is an amalgam of several similar event investigations. Details that would otherwise allow a specific company or person to be identified have been generalized, combined, or removed. The purpose of this brief study is to illustrate specific principles and...

by Heinz Bloch, P.E., Editor | Oct 10, 2020 | Learning from Mistakes, Plant Operations

At a gathering of reliability professionals in Texas, the coordinator invited questions from the audience. I was asked what I thought of installing flexible piping, joints, or connectors on centrifugal pumps. My answer was relatively short and specific. I’ve...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Aug 28, 2020 | Learning from Mistakes

Some years back, I was helping top management set the foundation for a new way of maintaining and operating their site’s critical manufacturing equipment. On one of the plant tours with a small group of supervisors, operators, and mechanics, I heard the faint...

by Randall Noon, P.E. | Aug 1, 2020 | Learning from Mistakes, Workforce Issues

The following account is a “think piece” (as my editor would say), concerning a management initiative. While the overall facts are genuine, the story posted here is based on several organizations that have gone through similar experiences. Once you read it, please...

by Randall Noon, P.E. | May 14, 2020 | Asset Management, Learning from Mistakes

The Second Law of Thermodynamics is the one about entropy tending to increase in a system as it moves toward equilibrium. A corollary of the Second Law relating to maintenance engineering is that all operating machinery eventually fails if left alone. It’s only...