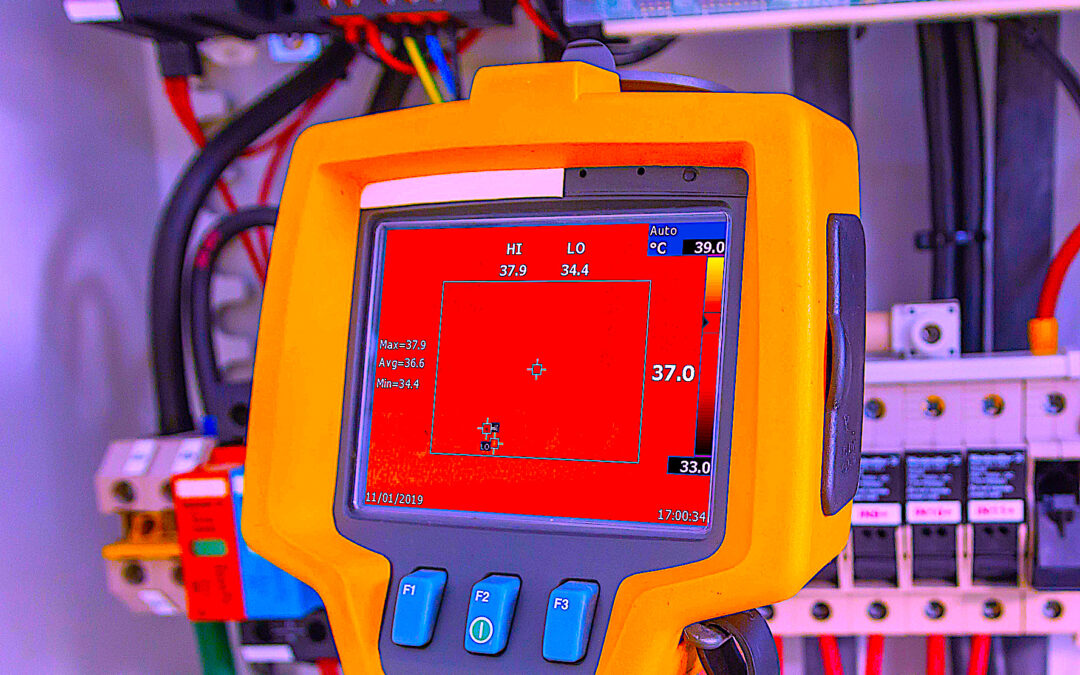

Thermal anomalies are not always as obvious as one might expect. Often, subtle thermal differences can be indicative of major problems. Because infrared thermography is a visual inspection technique, its effectiveness relies on the observation skills of the thermographer. Like any visual inspection technique, a thermographer must actively concentrate on the imagery displayed by the thermal imager.

ASKING THREE IMPORTANT QUESTIONS

Contrary to popular belief, humans are not inherently effective observers. Because humans tend to be casual in their observations, they frequently overlook subtleties. Whenever imaging, a thermographer’s eyes should always visually scan the monitor left to right and up and down while asking him/herself the following three questions:

1. What am I seeing?

2. Why am I seeing this?

3. Is this normal/reportable?

While this approach may sound cumbersome at first, this practice will soon become instinctive and can help prevent you from overlooking the subtle thermal patterns that can be indicative of serious problems.

IMPROVING TEMPERATURE-MEASUREMENT ACCURACY

As infrared technology has advanced, radiometers have become a common tool for many maintenance technicians and mechanics. Although radiometers are relatively easy to use, there are several important factors that influence the accuracy of a radiometer’s readings.

Infrared radiometers offer several advantages when it comes to temperature measurements. Measurements are non-contact, non-destructive and can be obtained quickly. Unfortunately, radiometers are not self-diagnostic and cannot warn the operator of erroneous readings. The following are some simple tips that can help to ensure accurate infrared temperature measurements.

♦ Target should be stationary and at a stable temperature with a dry surface

♦ Radiometer lens should be clean and free from obstructions

♦ Radiometer batteries should be fully charged

♦ IR temperature measurements should be made perpendicular to target

♦ IR radiometer should be operated at a distance to ensure that spot

measurement size is smaller than the target

♦ Accurate emissivity and reflected temperature values should be input

into the radiometer’s computer

Whenever possible, infrared readings should be correlated with known temperature values. If a discrepancy is observed, it could be due to a procedural error in measurement or the radiometer may require calibration.TRR

For more information on infrared temperature measurement, or to obtain information on thermographer training and certification, contact Infraspection Institute at 609-239-4788 or visit us online at infraspection.com.

EDITOR’S NOTE:

This Article Is Based On The April 11, and May 2, 2022

“Tips of the Week” From The IRINFO.org Website

CLICK HERE TO ACCESS THEM AND OTHER ARCHIVED TIPS

ABOUT THE AUTHOR

Jim Seffrin, CMRP, has been an Infraspection Institute Certified Infrared Thermographer since 1984. A co-founder of Jersey Infrared Consultants and a practicing thermographer with 36+ years of experience as an infrared consultant, he was appointed Director of Infraspection Institute in April 2000. For information on a wide range of topics related to infrared thermography and associated training and certification, visit IRINFO.org and/or infraspection.com, or email jim@infraspection.com.

Tags: reliability, availability, maintenance, RAM, photovoltaic systems, solar panels, infrared thermography, infrared cameras, thermographic imagers, imaging radiometers, infrared inspections, infrared temperature measurement, thermographer training