In parts I through IV of this series (see links below), we discussed the theories behind stator-slot signature in relation to Electrical Signature Analysis (ESA) and Current Signature Analysis (CSA). This week, we discuss a real-world example based on Fig. 1, and compare it to vibration data, including related vibration signatures.

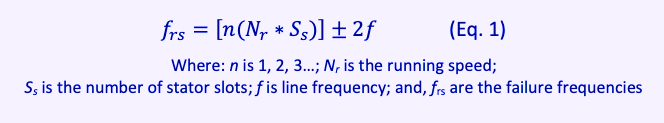

Vibration signatures related to stator beat, wedges, and electrical issues tend to occur as follows (Equation 1);

THE EXAMPLE

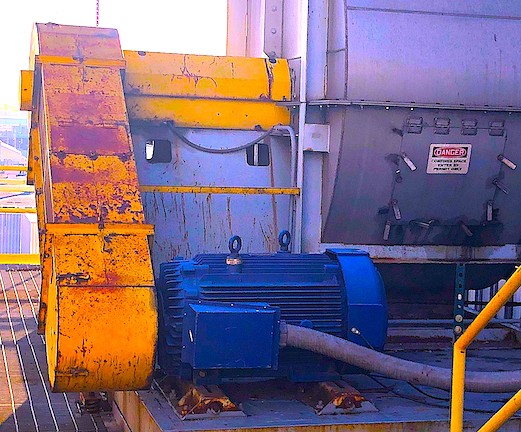

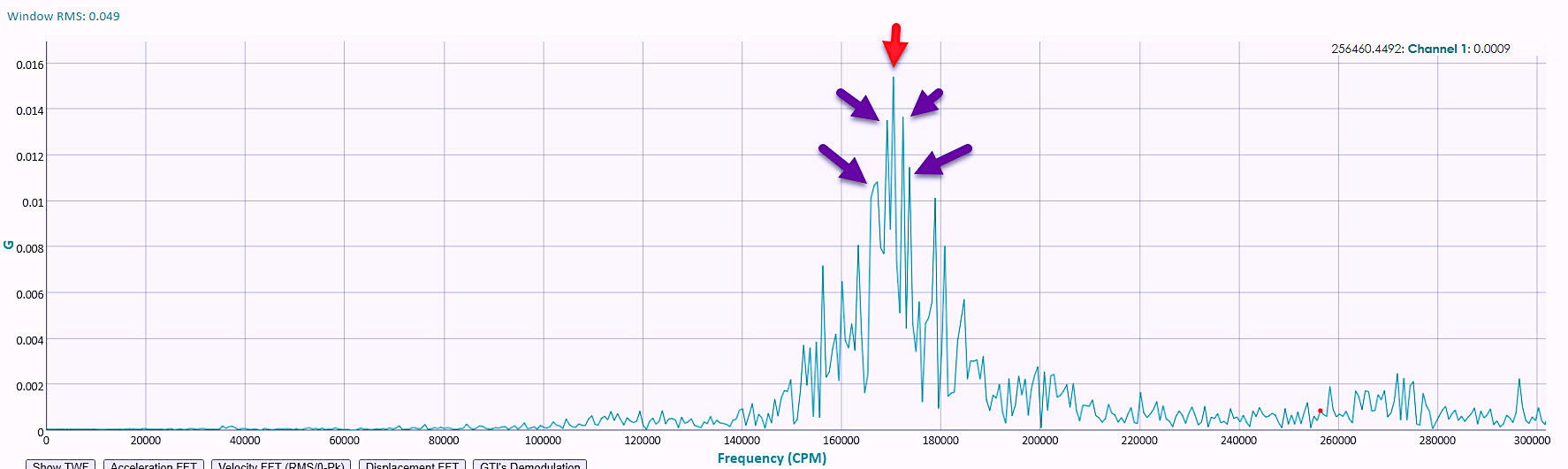

In the case of vibration analysis, the primary frequency, as well as the side bands, will be present. Depending on the type of issue and severity, the signature may be more than n = 1, and will usually show in acceleration. In the case of variable-frequency-drive (VFD) applications (such as that shown in Fig. 1), the value can be as much as n = 4 where there’s some type of stator-slot beat frequency, due to variations in the magnetic field in open slots.

Fig. 1. A 350-hp motor with fan operating on a VFD.

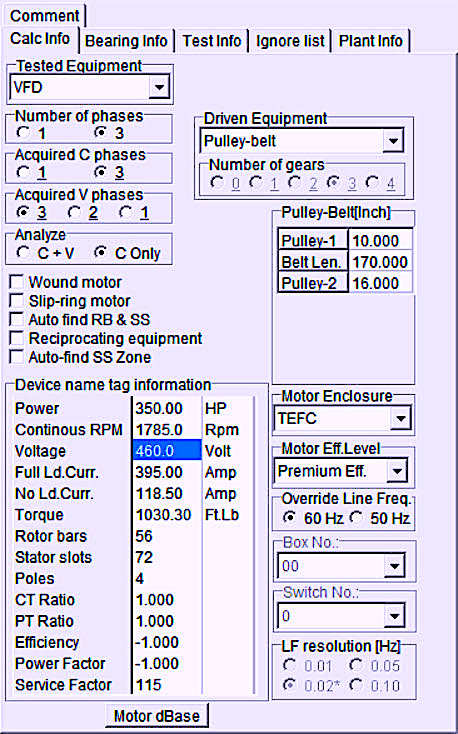

The nameplate for the motor in Fig. 1 is shown in Fig. 2 below.

Fig. 2. Nameplate information for the 350- hp motor shown in Fig. 1.

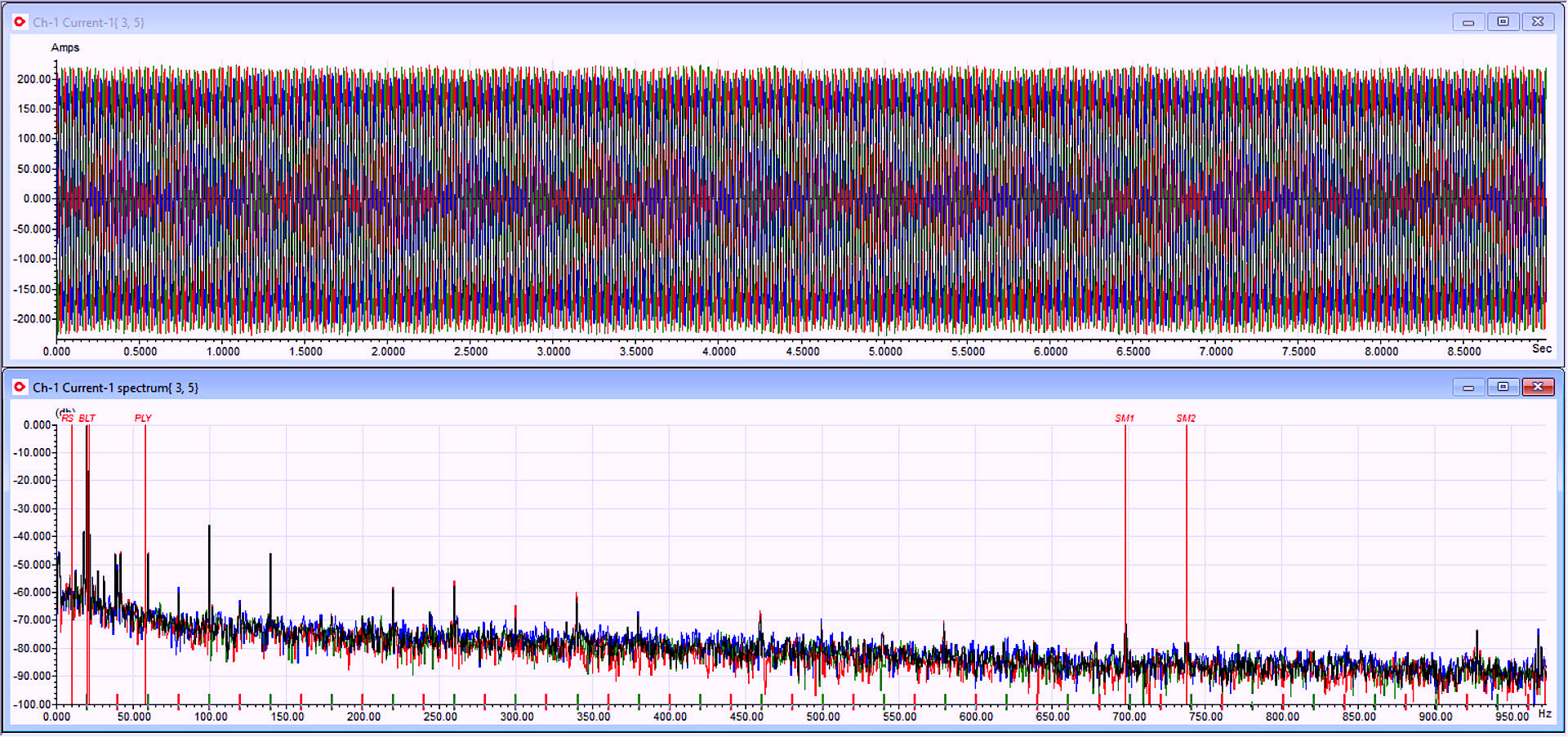

The Current Signature Analysis for this example is calculated using the number of stator slots (72), the running speed (9.9744 Hz) of 598.5 rpm, and a line frequency of 20 Hz.

The stator-slot frequencies would be (9.9744 Hz * 72 Ss) +/- 20 Hz which would produce 698.16 Hz and 738.16 Hz. The peaks show as in Fig. 3, and are about 10dB above the noise floor, which is an indicator of a stator-slot or coil condition. One cause of this type of condition may be the VFD settings or tuning. The signature may also be trended for changes, which would indicate impending failure.

Fig. 3. Current Signature Analysis stator signature.

To confirm the findings, vibration analysis may be performed, noting the speed at the time of testing, as shown in Fig. 4, where n = 4 with 2f sidebands. Note that the amplitude is low, indicating that the condition is present, but should be trended.

Fig. 4. Stator slot frequencies from drive-end vertical in acceleration.

LESSONS LEARNED & MORE

In the above case, a stator-slot frequency is found in a 350-hp motor operating on a VFD. By simply using Current Signature Analysis, the associated frequencies are found and amplitudes determined to review for severity. It’s also important to note that ESA technology was able to identify the frequency in the first harmonic where a different harmonic of the fault frequency could exist for vibration. This real-world example also shows how different technologies can be used to confirm findings.

In our next article, we’ll explore static eccentricity due to soft foot and alignment issues.TRR

Click On The Following Links To Read The First Three Articles In This Series:

“Part I, Electrical Signature Analysis (ESA) & Stator Winding Issues” (Oct. 3, 2020)

“Part II, Electrical Signature Analysis (ESA) & Stator Winding Issues” (Oct. 9, 2020)

“Part III, Electrical Signature Analysis (ESA) & Stator Winding Issues” (Oct. 17, 2020)

“Part IV, Electrical Signature Analysis (ESA) & Stator Winding Issues” (Oct. 24, 2020)

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: motors, drives, generators, wind turbines, wind energy, motor testing, reliability, availability, maintenance, RAM, electrical signature analysis, ESA, current signature analysis, CSA, motor current signature analysis, MCSA, vibration analysis