Best Practices: Can Lubrication-Related Field Tests Be Bypassed?

Best practices don’t involve re-inventing the proverbial wheel. They do, however, require familiarization with steps, procedures and, in this case, lube strategies that help end-user operations prosper.

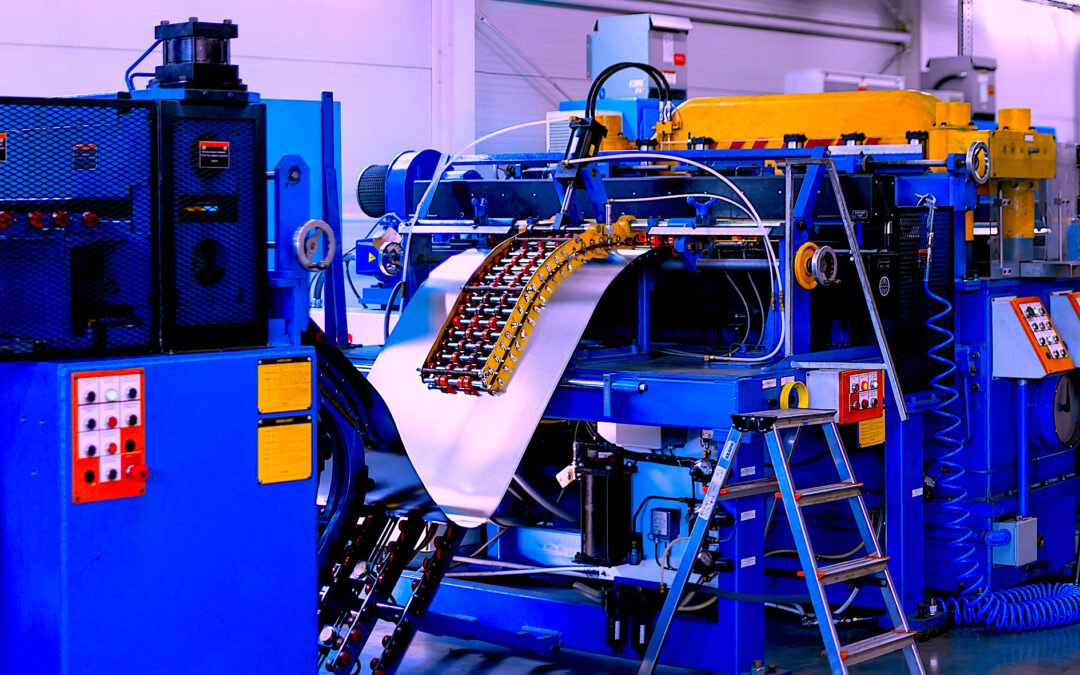

Lean Equipment Management: How To Put Its 7 Principles To Work (Part 1)

When looking at data for lean equipment management, RAM Pros must think beyond equipment “maintenance” issues. Look at how production flow gets interrupted AT equipment, not just because of it.

CAPEX For Best-Available Technology

Based on information available since 1962, a strong case can be made for allocating capital for equipment storage preservation. This article looks at the economics of outdoor storage yards.

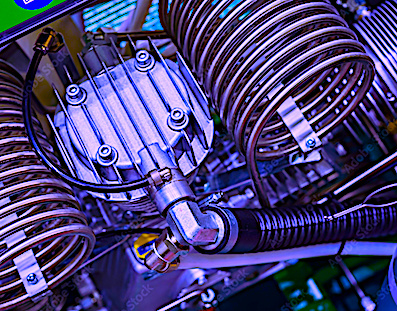

What Happens With ESA & MCSA When Applied To Synchronous Reciprocating Compressors?

The case study here involves one of the more challenging systems to analyze with Electrical or Motor Current Signature Analysis: that of a synchronous motor running a recip compressor.

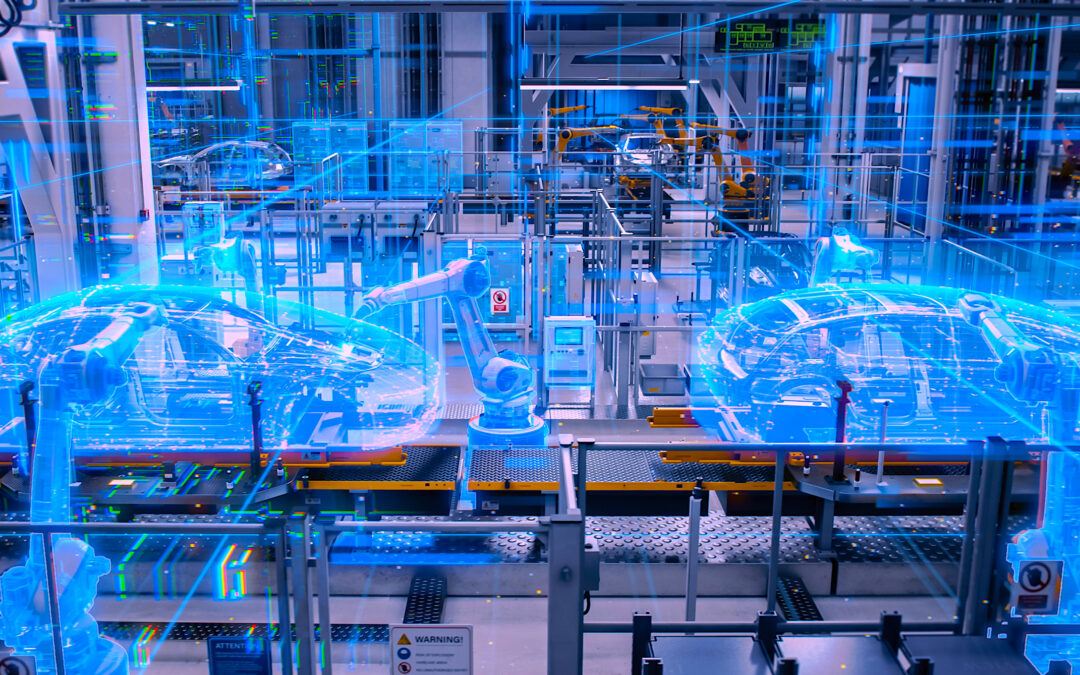

Customer Success Story: Proactive Supervision Program Yields 135% Productivity Improvement

A combined team delivered impressive results. This type of improvement allows a plant to drive more proactive maintenance, thus improving equipment availability and increasing revenue.

Lean Manufacturing: Leadership & Teamwork

Step up, RAM Pros: Coach top managers on leading reliability-improvement initiatives from a business perspective. Their “walking the talk” is crucial in building Lean Equipment Management cultures.

Sustainable Manufacturing Starts With Energy Management (Part I: Energy Timing & Form)

Energy is at the center of the quest for an environmentally sustainable future, including sustainable manufacturing. As the author often writes, RAM Pros play a vital role in achieving such objectives.

We Got Questions: Following Up On Detection Of Synchronous Machine Rotor Defects

What does failure of a synchronous motor look like? This article answers with a discussion of the approach to and results of a before-and-after failure analysis of a 4,500-hp, 1,800-rpm motor.

Storage Preservation As An Afterthought Will Fail

Mothballed machines left unprotected for as few as six months may not respond fully to belated protection methods. After six months of zero protection, things start heading south pretty quickly.

Lean Manufacturing: The 7 Principles Of Lean Equipment Management

A key success factor in Lean Equipment Management is deployment of several interdependent principles in ways that change the culture around that equipment. This column provides details.