We received several questions around our June 11, 2022, article (see link below) on the testing of synchronous machines, i.e., motors and generators) with Electrical Signature Analysis (ESA). Some readers wanted to know what failure of a synchronous motor looked like.

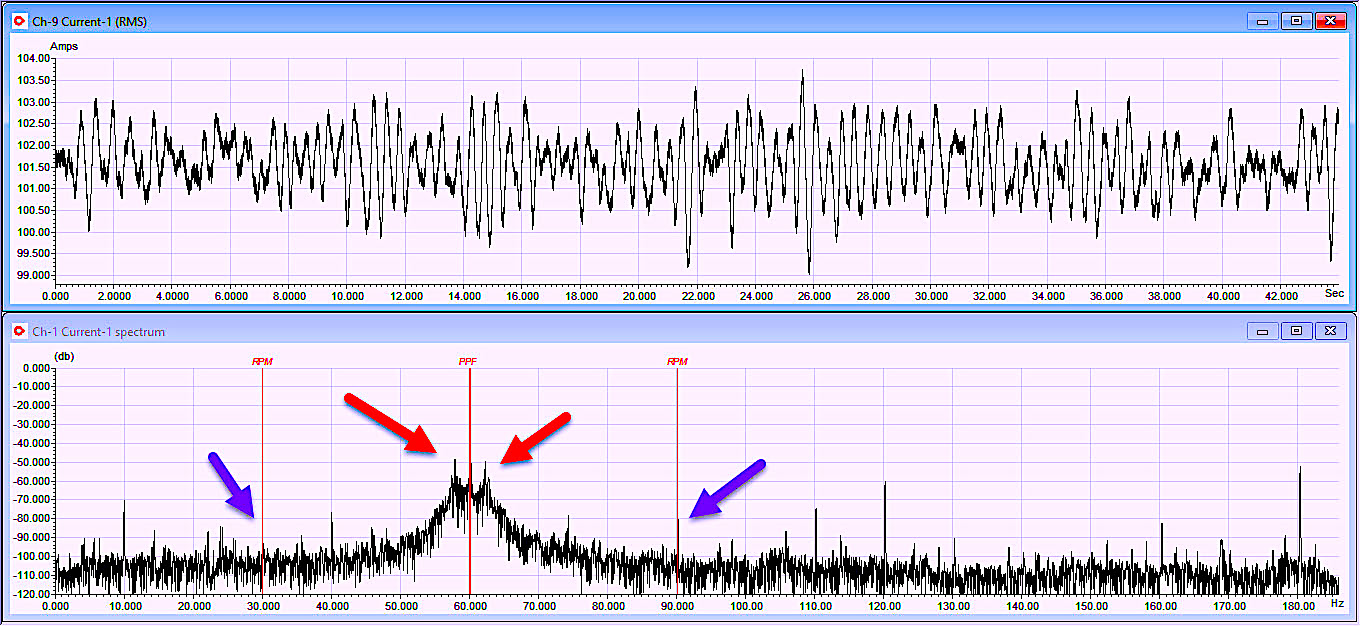

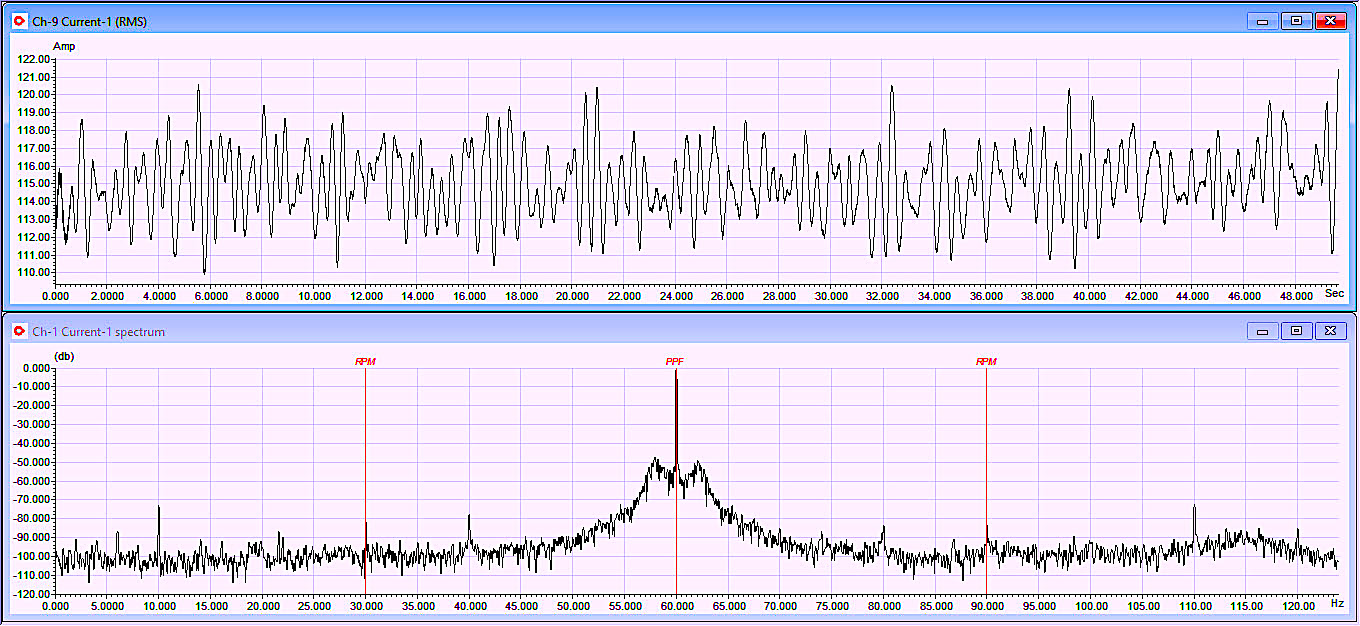

This week, in an attempt to address that question, we’re discussing a before-and-after failure analysis of a 4,500-hp, 1,800-rpm synchronous unit. The background includes some slow starts and a few other conditions that were largely not addressed until a predictive maintenance (PdM) test identified the unexpected pole-pass frequency shown in Fig. 1.

Fig. 1. Red arrows denote pole-pass frequency.

Purple arrows indicate running speed due to rotor defect.

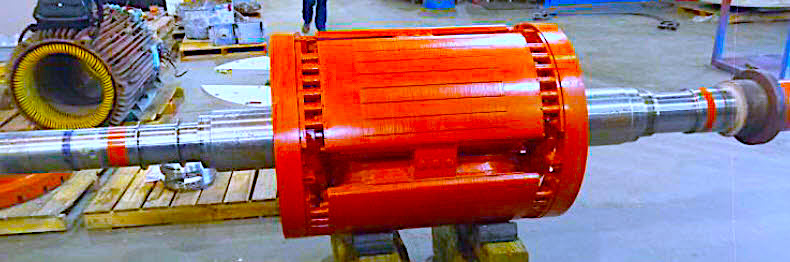

The rotor was tested and found to have greater than one Gigohm to ground at 500 Vdc. But there were some variations in the rotor-circuit test. The 1X rpm signature, while low, coincided with a low-level dynamic-eccentricity signature. The motor was subsequently disassembled, and the rotor was sent to a motor-repair shop (Fig. 2), where the exciter was removed (Fig. 3).

Fig. 2. Synchronous motor before disassembly.

Fig. 3. Rotor with exciter removed.

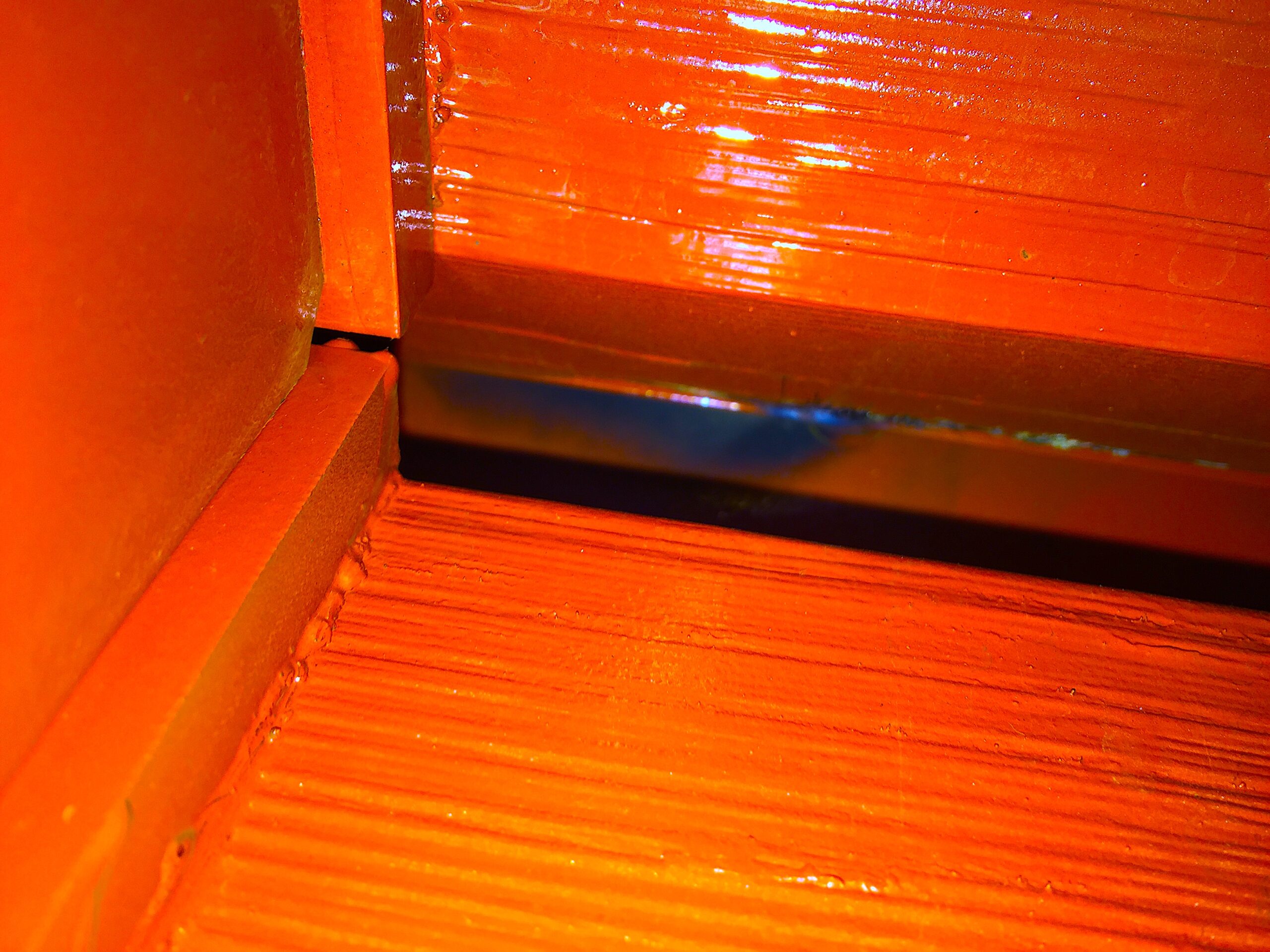

As shown in Fig. 4, a short was identified between conductors and an intermittent arcing location to ground. There was space between the coil and ground, in this instance, that caused the insulation-resistance test to miss the defect. However, rotor Motor Circuit Analysis (MCA) offline testing did show an inconsistent reading compared to prior test results indicating a coil to coil short.

Fig. 4. Location of defect on the rotor (short and intermittent ground).

The rotor fields were re-wound and the machine returned to service. Final ESA testing results are shown in Fig. 5. Note that the PPF style peaks have gone with only the compressor turbulence peaks that are consistent in machines in this type of application.

Fig. 5. Take note of lower 1X rpm peaks and

no sharp, distinct peaks on either side of line frequency.

In synchronous applications, machine defects and anomalies will appear as variants from what is expected in ESA. For rotor tests, the detection of pole-pass frequencies in standard applications, such as pumps and compressors, are indicators of rotor-circuit defects. In next week’s article we will review synchronous machines in reciprocating compressor applications.TRR

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Maintenance and Reliability Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, electric motors, generators, synchronous machines, pumps, compressors, motor testing, generator testing, Electrical Signature Analysis, ESA, Motor Current Analysis, MCA