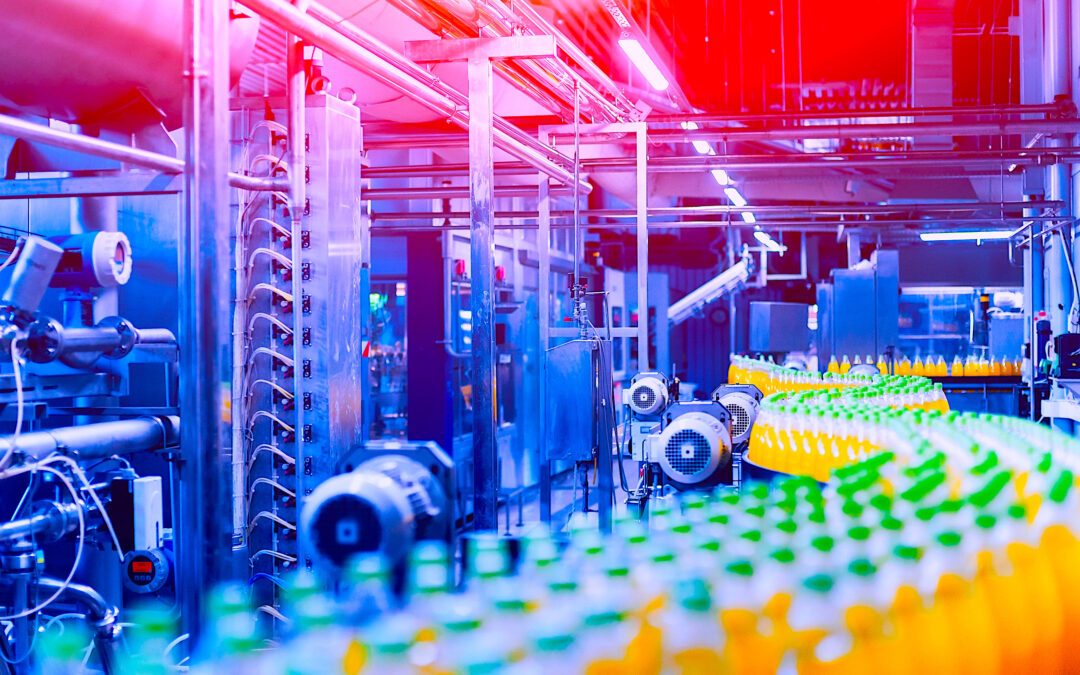

Lagging Metrics For Asset Management: OEE’s Second Element (Yield/Speed, Part 4)

RAM pros usually don’t think about the market- and marketing-induced causes for Yield/Speed issues (poor asset performance), but they’re very real. And their impact on profitability can be significant.

The RAM Review Version: A Visit From St. Nicholas

Who hasn’t heard or read the original version of this classic holiday poem? But have you heard or read this version? It’s been reworked slightly and is offered here specifically for RAM professionals. Enjoy!

OEM Knowledge: Indispensable In Setting Up Maintenance Programs

Machine-design considerations include information that’s crucial in building PM programs for new plant assets. Tapping into it requires end-users to understand/communicate with OEM designers.

Beware Flawed Reward Systems (There’s A Big Cost)

According to the author, a disturbing gap between what’s said and what’s done in equipment maintenance and reliability exists, and we don’t seem to be closing it. That includes how managers are rewarded.

Making Sense Of Sense In Troubleshooting

Pass this “Ted” talk on: Despite countless tools for troubleshooting today’s plant equipment, our six primary senses can still provide powerful insight. And at no cost.

Real-World Advantages: Oil-Mist Payback 101

Many times, oil-mist lubrication might not be considered because plant decision-makers don’t know about its simplicity, its relative low cost, and/or its technical merits.

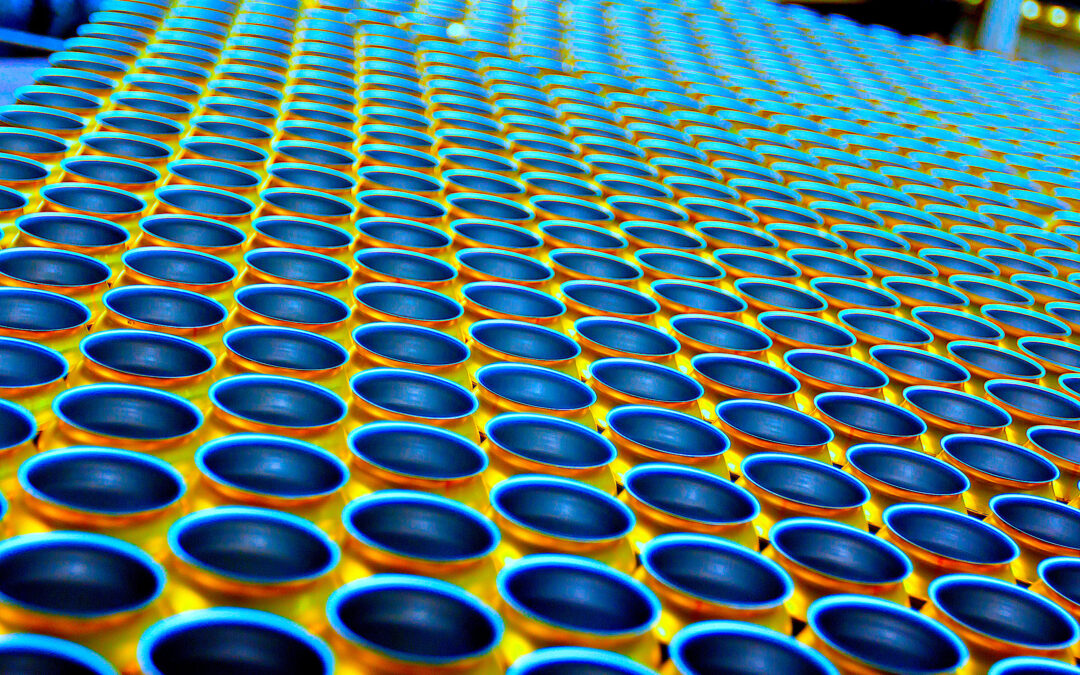

Lagging Metrics For Asset Management: OEE’s Second Element (Yield/Speed, Part 3)

While running equipment too hard and beyond its Highest Sustained Rate of production is common, there are numerous production-induced causes for Yield/Speed losses. They’re highlighted here.

Critical Thinking & Troubleshooting Electric Machines

In much of today’s information from the Internet and print sources, we’re getting what amount to programmed responses, often with a marketing tune in the background.

Tips For Reliability Improvement Consultants And Their Clients

All consultants are not created equal, nor are all clients. A seasoned RAM consultant himself, the author offers some advice to help improve relationships that improve reliability throughout industry.

Oil Mist Customer Success Story: Northeast U.S. Refinery (Four-Cell Cooling Tower Application)

Yearly failures of multiple cooling tower gearboxes were a costly problem for one U.S. refinery. An oil mist system solved that expensive headache in short order. And with just a 1-year payback.