In Part 3 of this series (see links below ) on Yield/Speed, the second element of Overall Equipment Effectiveness (OEE), we discussed production-induced losses. This week, we address market and/or market- and marketing-induced Yield/Speed losses. One doesn’t commonly think about the market- and marketing-induced causes for poor asset performance, but the impact can be significant. In a nutshell, our marketing teams are responsible for selling everything that we can make. It is also important that they not commit the plant to product and/or packaging solutions exceeding the technical limitations of the plant and its equipment.

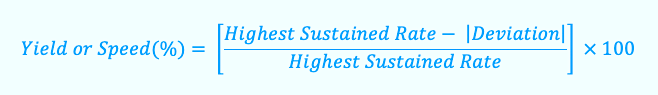

As previously discussed, I’ve created a workaround to the traditional equation for Yield/Speed to address the scenario where Yield/Speed can exceed 100%, which creates a problem with the OEE metric. To arrive at this adjusted Yield/Speed, subtract the absolute value of any deviation in Yield/Speed from the Highest Sustained Rate, divide by the Highest Sustained Rate, and multiply by 100 (Form. 1). My workaround to the Yield/Speed metric penalizes operating below or above the Highest Sustained Rate equally.

Form. 1. The Troyer workaround formula to eliminate the

possibility that the Yield/Speed metric can exceed 100%.

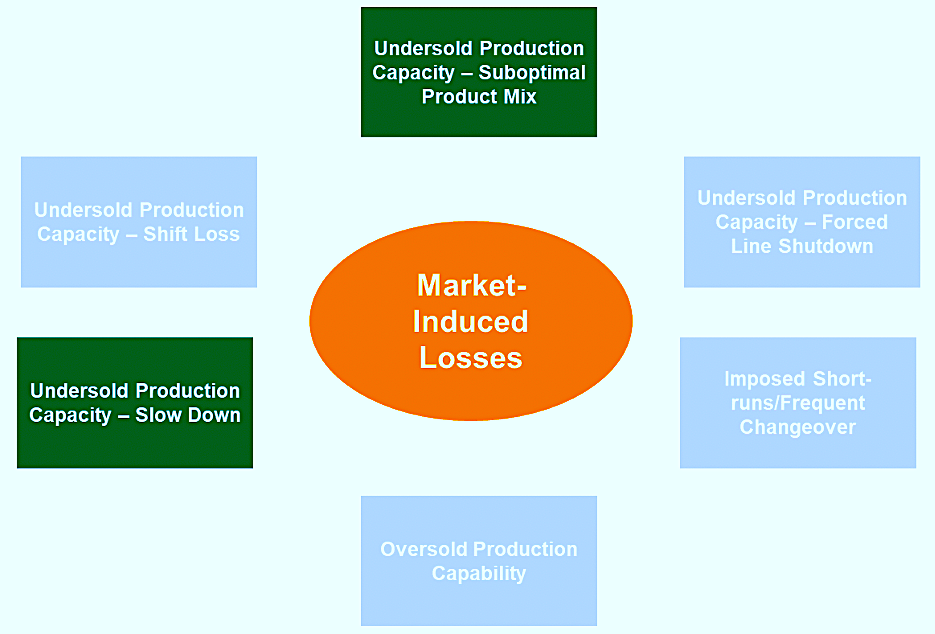

Sometimes, the market for goods and services simply doesn’t cooperate, which may force the plant to slow its production output to match market conditions and/or produce a mix of products that aren’t ideal from a profit perspective (Fig. 1). Let’s explore these scenarios in more detail.

Fig. 1. Common marketing-induced causes for reduced Yield/Speed performance.

MARKETING-INDUCED OEE LOSSES

When the market for products is soft and we suffer market-induced Availability and/or Yield/Speed impacts that compromise our OEE performance, we’re often left with no option but to adapt and survive as we wait for better days to return. Marketing, on the other hand, relates to how we respond to market conditions to deliver products that are in sufficient demand that enable the firm to turn a profit. It’s the responsibility of our colleagues in marketing to understand and anticipate this market demand and, in some cases, create or increase the demand with promotions and advertising. However, sometimes this process fails, and we’re forced to produce a suboptimal product mix, change over production too frequently, or slow it down if the marketing team has oversold the capabilities of the operation.

Undersold Production Capacity – Suboptimal Product Mix. A suboptimal product mix doesn’t specifically affect Yield/Speed or, for that matter, OEE. It can, though, affect our profitability. If the marketing team fails to promote and sell our most profitable offerings, profitability takes a hit.

In down markets, in some instances, it’s necessary to produce a mix of products that fails to deliver ideal profits but does keep the plant running and covers overheads. Such a decision does not specifically affect Yield/Speed or OEE, but it’s worth noting because of the impact on a firm’s profitability. While OEE doesn’t specifically consider profitability, profit is ultimately the mission of a business. So, as asset managers, we must keep our eyes on the prize.

Oversold Production Capability. In some cases, the marketing and sales team simply commits beyond the production capability of the plant and its equipment. This overcommitment can take the form of overselling the production capacity, selling a product variation that exceeds the capability of the plant and/or creating a packaging solution that exceeds the capability of the packaging line.

Consider the example of a manufacturer of canned beverages that are packaged into cartons of 12 items (a 12-pack). Imagine a scenario where the marketing department decides upon a marketing campaign to promote the beverage, in which, for a limited time, a 12- pack carton containing 11 cans and a special promotional t-shirt will be offered. That could create real problems.

First, the equipment for packaging a 12 pack is designed to do so for 12 cans that are identical in dimension and mass. A t-shirt doesn’t match the specified criteria. Even if one were to package the t-shirt in a dimensionally compliant can, it still wouldn’t be compliant on mass. This can really slow down a packaging machine! Moreover, the beverages are all identical, t-shirts come in different sizes, which creates a labeling challenge for the plant. Somehow the plant must accurately label the 12-pack as small, medium, large, or extra-large, which is still another challenge that can slow Yield/Speed and adversely affect OEE.

It’s very important that marketing organization understand what the plant and its equipment can and can’t do and market and sell within those limits.

Imposed Short-Runs/Frequent Changeover. Marketing teams typically to want to respond to customers needs and deliver what the customer wants. This is generally a desirable quality. However, in addition to sometimes committing the plant to produce beyond its capabilities, there are occasions where the operation is committed to too much variability or short-runs of production that impact Availability and Yield/Speed. This variability can take the form of the product, its packaging, its labeling/and or its distribution.

CONCLUSIONS

This article concludes our discussion on Yield/Speed, the second element of OEE. As we’ve discussed in this short series, Yield/Speed losses can be equipment-, production-, market-, and/or marketing-induced. Market- and marketing-induced losses are often overlooked by asset managers, but they’re very real.

In some instances, market conditions can’t be addressed (particularly during economic slowdowns, pandemics, etc.). Still, we must make sure we are manufacturing, packaging, and delivering products that meet customer demands and enable the business to maximize asset performance and profitability.

In the next issue of The RAM Review, we’ll address Quality, OEE’s third element.TRR

REFERENCES

Troyer, Drew (2008-2021). Plant Reliability in Dollars & $ense Training Course Book.

Click The Following Links To All Previous Articles On Yield/Speed

ABOUT THE AUTHOR

Drew Troyer has over 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 300 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. A Certified Reliability Engineer (CRE) and a Certified Maintenance & Reliability Professional (CMRP), he holds B.S. and M.B.A. degrees. Drew, who also earned a Master’s degree in Environmental Sustainability from Harvard University, is very passionate about sustainable manufacturing. Contact him at 512-800-6031, or email dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, metrics, key performance indicators, KPIs, Yield/Speed, OEE