by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Mar 28, 2021 | Asset Management, RAM Tools & Methods

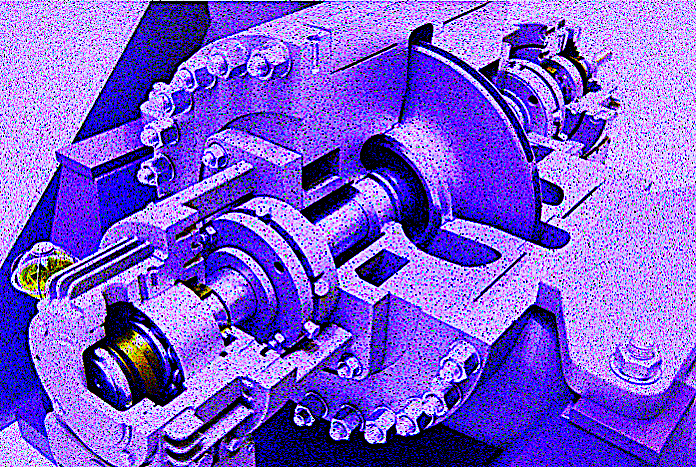

The first article in this short series on precision parts (March 21, 2021) discussed the topic of designing for reliability (see link below). Here in Part II, the focus is on the rebuild process. Figure 1 illustrates the process flow I recommend for management...

by Heinz Bloch, P.E., Editor | Mar 27, 2021 | Lubrication Corner, RAM Tools & Methods, The Bloch Files

Every so often, it’s time to ask if our knowledge of a reliability subject is up to date. The need to stay abreast of grease technology is a case in point: One case study showing the benefits of doing so dates back to around 2006. That’s when a Texas-based...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Mar 21, 2021 | Asset Management, RAM Tools & Methods

Executing precision maintenance work requires a combination of skills, effective work instructions and methods, correct and properly calibrated tools, and, of course, the right parts that are in the right condition. Yet, when conducting failure investigations and...

by Jim Seffrin, CMRP | Mar 13, 2021 | IR Thermography, RAM Tools & Methods

Non-contact thermometry provides a means for rapidly measuring object temperatures. To ensure measurement accuracy, all error sources must be considered and properly addressed. This article discusses how to measure and compensate for Reflected Temperature using the...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Mar 12, 2021 | RAM Tools & Methods, Workforce Issues

In my early years working as a tool designer, I had the opportunity to work alongside some traditional old-school tool and die makers. They all took great pride in their tools, i.e., the tools of their trade. They treated their tools with great care and respect, day...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Mar 6, 2021 | Maintenance Management, Newsletter Column, RAM Tools & Methods

Much attention is paid to the foundational elements that are necessary to ensure equipment and process reliability in plants. Still, in the end, reliability really comes down to people employing tools and materials to effectively execute maintenance plans. That is the...

by Heinz Bloch, P.E., Editor | Mar 5, 2021 | Asset Management, RAM Tools & Methods, The Bloch Files

Years ago, I had to learn about the associated filter-related terms “Beta Ratio” and “Beta Efficiency.” I had read that we can calculate fluid-filter efficiency after ascertaining the Beta Ratio. By convention, Beta Ratio is a measure of a filter’s efficiency....

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Feb 28, 2021 | Newsletter Column, RAM Tools & Methods

Mean time to repair/restore (MTTR) is the maintenance metric that summarizes the historical time taken to make necessary repairs and adjustments to return equipment to its desired operational state. In other words, “Fix it fast, fix it right.” When I ponder the...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 22, 2021 | Newsletter Column, RAM Tools & Methods

I was recently listening to a radio interview of the great Frank Oz. You may recall that Oz is the master puppeteer and voice behind such iconic Muppets and Sesame Street characters as Miss Piggie, Fozzie Bear, Animal, Cookie Monster, Grover, and Bert, as well as Yoda...

by Jim Seffrin, CMRP | Feb 6, 2021 | Electrical Reliability, IR Thermography, RAM Tools & Methods

It’s a common question: “How often should electrical systems be thermographically inspected?” Historically, accepted industry practice has recommended that infrared inspections be performed annually. However, site-specific conditions may dictate considerably...