by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Mar 15, 2020 | Asset Management, RAM Tools & Methods

Executing equipment maintenance is as much about behaviors as it is about skills. Think of a skill as knowledge about HOW to do something, while a behavior is related more to understanding WHY—basically having an appreciation for the motivation. Behaviors are very...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Mar 7, 2020 | Plant Operations, RAM Tools & Methods

Overall equipment effectiveness (OEE) has been used as one of the more important manufacturing metrics since Total Productive Maintenance (TPM) came to the U.S. in the late 1980s. It’s the primary measure used in TPM to identify and quantify the major...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Mar 1, 2020 | RAM Tools & Methods, Safety Matters, The Sustainable Plant

Fugitive emissions, are a concern across the industrial landscape. Although this article focuses on leveraging predictive maintenance (PdM) to combat the problem in the natural-gas arena, the suggested strategies and tactics can be adapted in any operation where...

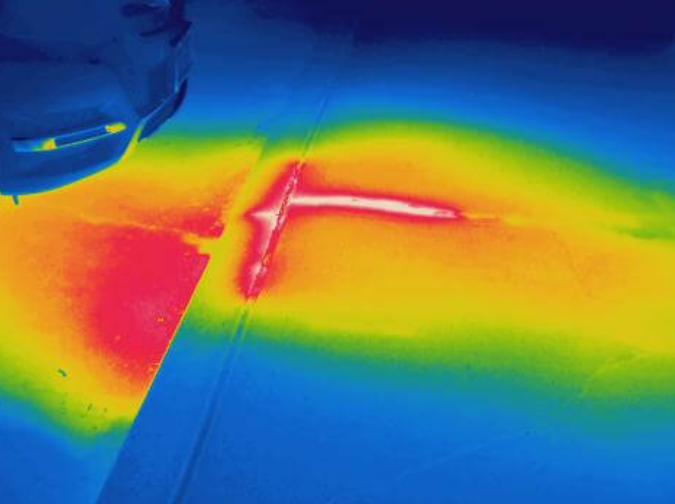

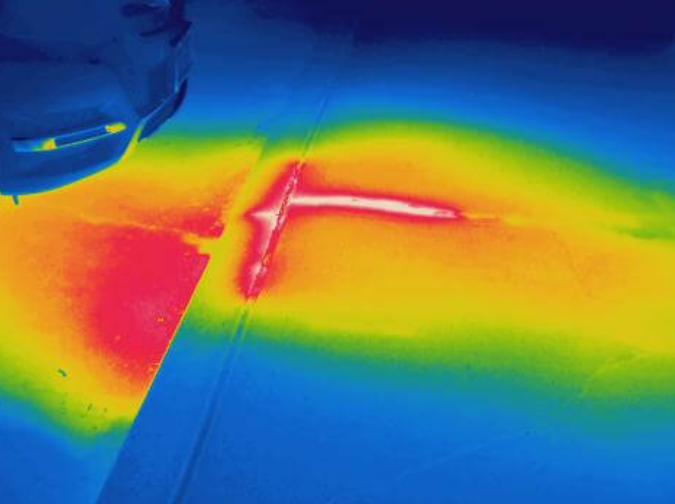

by Jim Seffrin, CMRP | Feb 29, 2020 | IR Thermography, RAM Tools & Methods

Leaks are a common problem with underground piping systems. Under the correct conditions, infrared (IR) thermography can help to detect evidence of leaks from buried piping systems that carry hot or cold product. When a leak develops in a buried piping system, fluid...

by Heinz Bloch, P.E., Editor | Feb 21, 2020 | RAM Tools & Methods, The Bloch Files, Workforce Issues

You may recall hearing about (or could have possibly experienced) this type of situation in your workplace: There are times when we attend presentations by competent technical people, including colleagues, whose relevant requests are eventually ignored by their...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Feb 14, 2020 | Cut the FLAB, RAM Tools & Methods

We’ve all heard that “what gets measured gets done.” That’s because metrics and key performance indicators (KPIs) drive behaviors. Unfortunately, most of our maintenance and reliability KPIs are lagging in nature. While they reveal where we’ve been—which is...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 13, 2020 | Newsletter Column, RAM Tools & Methods

In the world of essential capital assets (facilities, plants, equipment, infrastructure, buildings, etc.), we must embrace the guiding principles of continuous, incremental improvement. Whether it’s discreet manufacturing, primary metals, petrochemical, foods,...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Jan 11, 2020 | Maintenance Management, Plant Reliability in Dollars and $ense, RAM Tools & Methods, The Sustainable Plant

Continuing with this “Reliability Resolution 2020” series focusing on precision maintenance, I am expanding upon the theme developed in the first installment (posted on TheRamReview.com, Jan. 4, 2020). In that article, I challenged readers to evaluate the measurable...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Jan 4, 2020 | Cut the FLAB, Maintenance Management, Plant Reliability in Dollars and $ense, RAM Tools & Methods, The Sustainable Plant

Happy New Year! It’s the time when we tend to reflect on the past year and resolve to make changes that will make this year even better. It’s particularly beguiling that this is the year “2020”—which is the term that optometrists and ophthalmologists use...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Dec 22, 2019 | Cut the FLAB, Maintenance Management, RAM Tools & Methods

Of all the various strategies associated with the maintenance and reliability of production equipment in the manufacturing and process industries, none is more salient than precision maintenance when it comes to increasing production availability and reducing...