Continuing with this “Reliability Resolution 2020” series focusing on precision maintenance, I am expanding upon the theme developed in the first installment (posted on TheRamReview.com, Jan. 4, 2020). In that article, I challenged readers to evaluate the measurable effects of precision maintenance and convert those effects into machine-life-extension calculations. Here, in this second installment, my focus is on the environmental benefits of precision maintenance.

(EDITOR’S NOTE: This week’s installment, as noted in the text at the end of the Jan. 4 article, was originally scheduled to run as the third part of this series. The change in the order of publication means the previously scheduled installment about the cost benefits of precision maintenance in terms of increased uptime, reduced repair costs, and increased energy efficiency will actually run as the third, and final, part of Drew’s “Reliability Resolution 2020” series.)

All manufacturing processes employ materials, energy, and information to convert raw materials into finished goods that people demand and for which they’re willing to pay. The use of materials and energy clearly has environmental consequences. While precision maintenance probably can’t substantively impact the raw materials employed in the direct production of whatever the plant makes, it can substantively affect the amount of energy consumed in the direct production process and the energy and materials required to purchase, transport and install machines used in the production process or the parts required to rebuild existing systems.

Increasingly, organizations are expanding the corporate mission beyond profits/shareholder value, safety, and customer satisfaction to include environmental sustainability. Let’s explore how precision maintenance can support your goals to reduce your company’s environmental footprint and better serve your environmental sustainability mission objectives.

CONSIDERING ENERGY CONSUMPTION

Friction is the difference between machines that run loud, rough, and hot and those that run quiet, smooth, and cool. Precision maintenance takes dead aim at the sources of friction, i.e., mechanical looseness and poor electrical conductivity, unbalance (mechanical or electrical), misalignment, and poor lubrication. Mechanical friction and electrical resistance (I2R losses) are parasitic uses of energy that manifest in the form of vibration, noise (acoustic emissions) and heat.

Noted tribologist Peter H. Jost suggested that reducing friction through proper lubrication practices alone can reduce energy consumption by a whopping 7.5%. Some experts suggest that precision shaft alignment alone can reduce energy consumption by as much as 10%. Comparing the loudest, roughest, and hottest machines to those that are the quietest, smoothest-running, and coolest, I estimate that we conservatively have a 5% to 15% energy- consumption-savings opportunity for typical plant-equipment types. This has both economic and ecological implications.

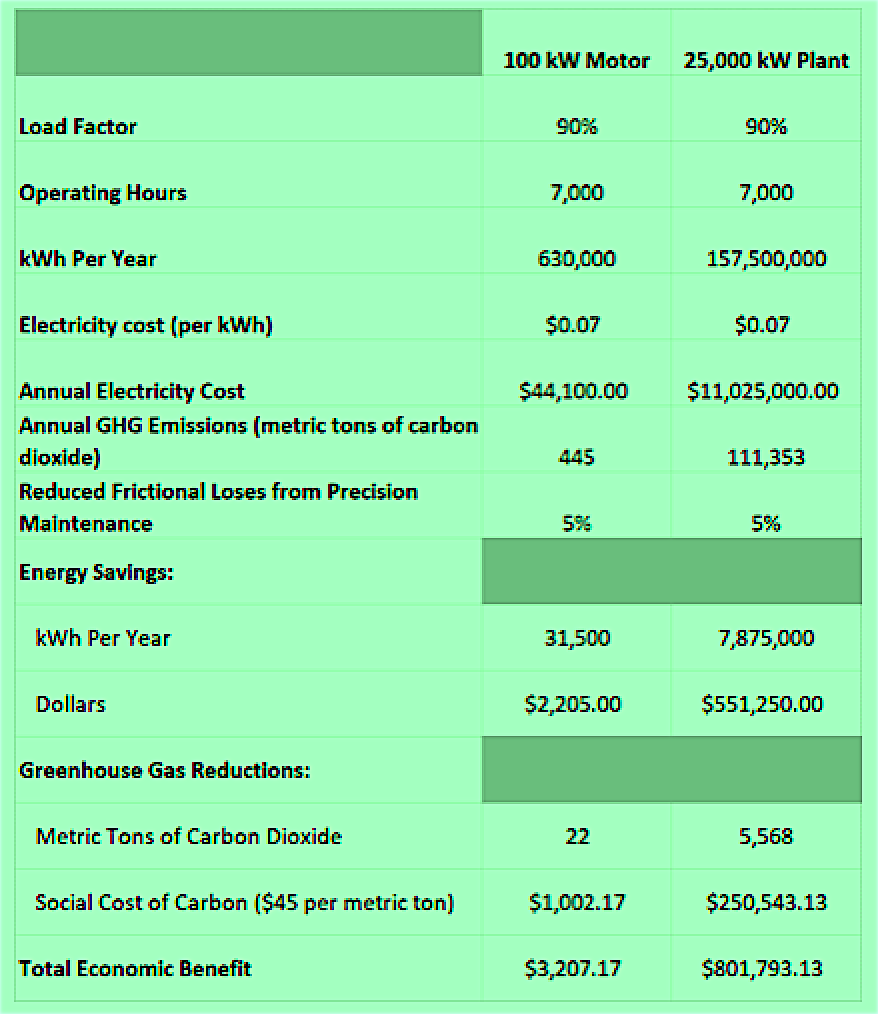

Let’s first look at the economic implications. Suppose that a 100-kW electric motor runs 90% loaded over a 7,000-hr. production year. That motor utilizes 630,000 kWh of electricity per year. Assuming electricity costs $0.07 per kWh, the annual cost to energize the motor is $44,100. Suppose that, through precision maintenance, we can reasonably reduce friction related energy losses by 5%. Our savings would be $2,205 per year for the one electric motor.

Now, let’s say that the plant has 25,000 kW of power deployed at 90% load for a 7,000-hr. production year, and we can reduce frictional energy losses by 5% plant-wide. The annual savings would be $551,250.

Consider these simple examples, then plug in your own numbers. (And, if you took the precision-maintenance challenge described in my Jan. 4, 2020 article, you can enter actual numbers for the reduction in frictional losses.) The dollar savings associated with reducing frictional losses with precision maintenance go straight to the bottom line.

But hold the presses: There’s more.

The generation of power releases carbon dioxide and other greenhouse gases (GHGs), which contribute to climate change. The U.S. Environmental Protection Agency (EPA) estimates that there is 0.707 kg of carbon dioxide (or its equivalent in other GHGs) released for every kWh of electricity. So, using our example of a 100-kW motor operating at 90% load for a 7,000-hr. year emits 445.41 metric tons of carbon dioxide, or its equivalent, per year. Reducing frictional losses by 5% reduces our carbon footprint by 22.27 tons per year. Expanding the analysis to our example of a plant deploying 25,00-kw of power at 90% load over a 7,000-hr. production year, , a 5% reduction in frictional losses results in a 5,567.63 metric ton reduction in GHG emissions.

So what does this mean to you? First, these are numbers that you can report to the public, particularly if you’ve taken my challenge to measure energy consumption before and after deploying precision maintenance. It’s good public relations (PR) and good marketing as a greater percentage of the population becomes concerned about anthropogenic climate change. However, there could be a financial impact as well.

Opinions vary about the social costs of carbon (SCCs), i.e., the social costs associated with each ton GHGs emitted and presented and carbon-dioxide equivalent units. The most commonly cited figure is $45 per ton.

The idea of a carbon tax continues to gain traction globally and has already been implemented in some areas (e.g., California). If the concept of a carbon tax catches on, the previously discussed public-relations benefits become real dollars. For example, assuming $45 per metric ton, a 5% reduction in frictional losses through precision maintenance is worth a little over $1,000 per year for our 100-kW-electric-motor example, and more than $250,000 per year for our 25,000-kW plant-wide example. Keep in mind that those types of SCC savings are in addition to the actual economic savings previously discussed. All figures for the economic and environmental impact analysis are summarized in the Table I.

Table I. Economic- and environmental-impact analysis associated with

reduction of frictional energy losses through proactive maintenance.

LIFE-CYCLE INVENTORY ANALYSIS

In the first installment (Jan. 4, 2020) of this Reliability Resolution 2020 series, we calculated the potential life-extension opportunity associated with precision maintenance. When machines run quietly, smoothly, and cool, they not only consume less energy, they last longer because less friction means less wear. In the example from the first installment, we estimated that by focusing on Fasteners, Lubrication, Alignment and Balance (FLAB), the foundation of precision maintenance, we could increase the MTBF by a factor of 3.66 (from 12 to 44 months in our example). This type of result has significant environmental implications.

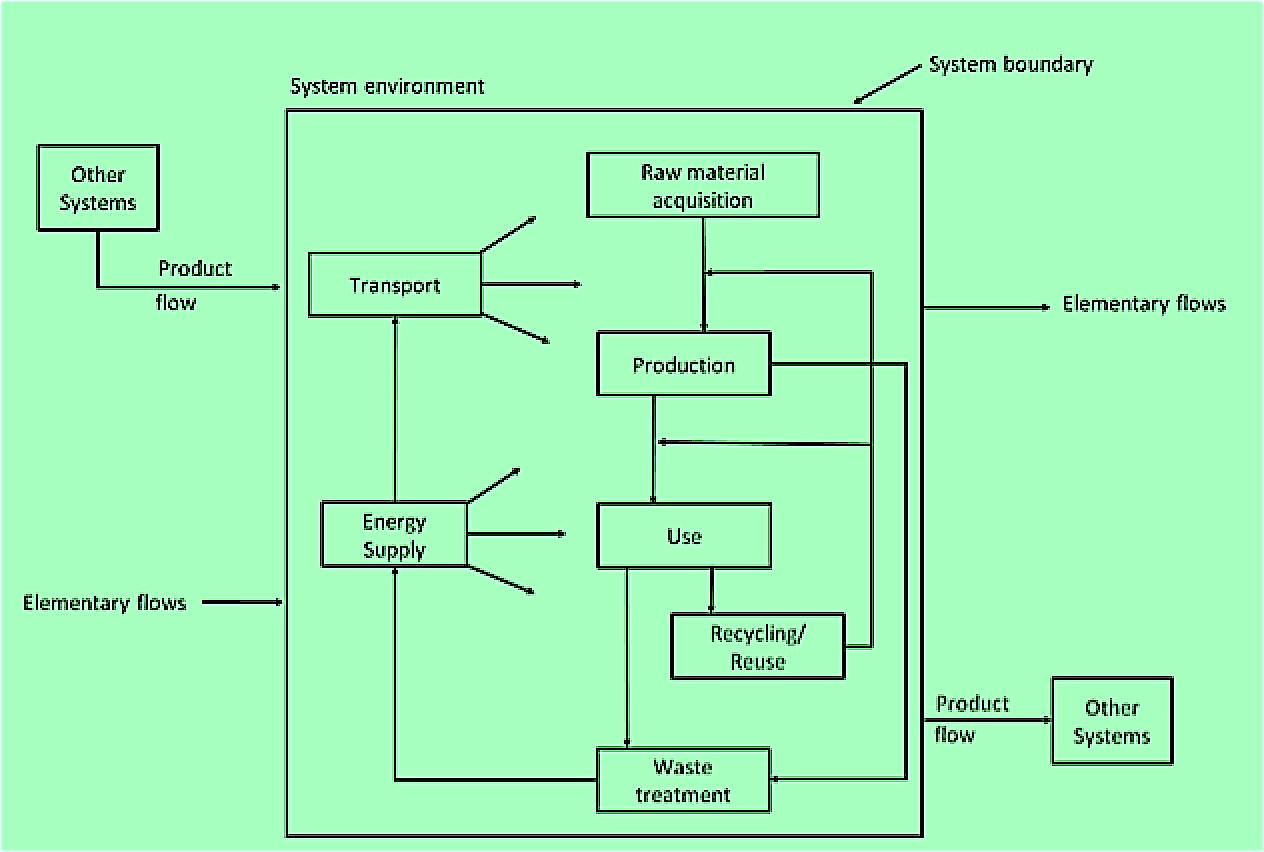

In the field of environmental sustainability, we employ a process called Life-Cycle Inventory Analysis (LCIA). The purpose of LCIA is to calculate the overall environmental impact of the acquisition of materials, production, use, recycling/reuse and waste treatment, and required energy and transport associated with the creation and use of goods and services that consumers demand (Fig. 1). The LCIA process is defined in ISO Standards 14040 and 14044. These ISO standards are essential elements of ASTM Standards for Sustainable Manufacturing that have been created by the ASTM E60.13 committee (of which I’m a voting member). The current ASTM Standards for sustainable manufacturing include E29816-15, E3012-16, E2987/E2987M-16, and E3096-18. More related standards are under development.

While it’s beyond the scope of this article to teach the LCIA process, we can simply conclude that if we calculate the environmental LCIA impact associated with the acquisition or rebuild of any component or system AND we increase the time between replacements from 12 to 44 months, we will have fundamentally decreased our environmental impact by 73% (excluding direct energy use associated with the machine’s use, which we addressed previously). Adding this to the previously discussed energy savings, precision maintenance can have an enormous positive environmental impact.

Fig. 1. Life-cycle inventory analysis (LCIA) flow diagram, per ISO 14040.

COMING UP

In this second installment of my three-part Reliability Resolution 2020 series, I’ve challenged you to test the opportunities associated with the implementation of precision maintenance (noted in the Jan. 4 article). Here, I’ve demonstrated the energy savings and environmental impacts. In the third (final) installment, I’ll illustrate how to calculate the impact of precision maintenance in Dollars & $ense. I’m hoping that you’ll accept all of these challenges.

Again, here’s wishing the RAM community a very Happy and Reliable 2020!TRR

(AUTHOR’S NOTE: I thought very seriously about addressing the relationship between reliability and safety. I have less hard data on that subject, but suffice it to say, reliable equipment requires less work and is more predictable. In turn, there are fewer opportunities for people to be put in harm’s way. The law of large numbers dictates that precision maintenance should produce safer equipment, which drives improved profitability, environmental performance, and safety. That’s the reliability trifecta!)

ABOUT THE AUTHOR

Drew Troyer has 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 250 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees, and is Master’s degree candidate in Environmental Sustainability at Harvard University. Contact him directly at 512-800-6031 or dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, energy efficiency, social costs of carbon, fasteners, lubrication, alignment, balance, vibration,