by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 6, 2021 | Lubrication Corner, RAM Tools & Methods

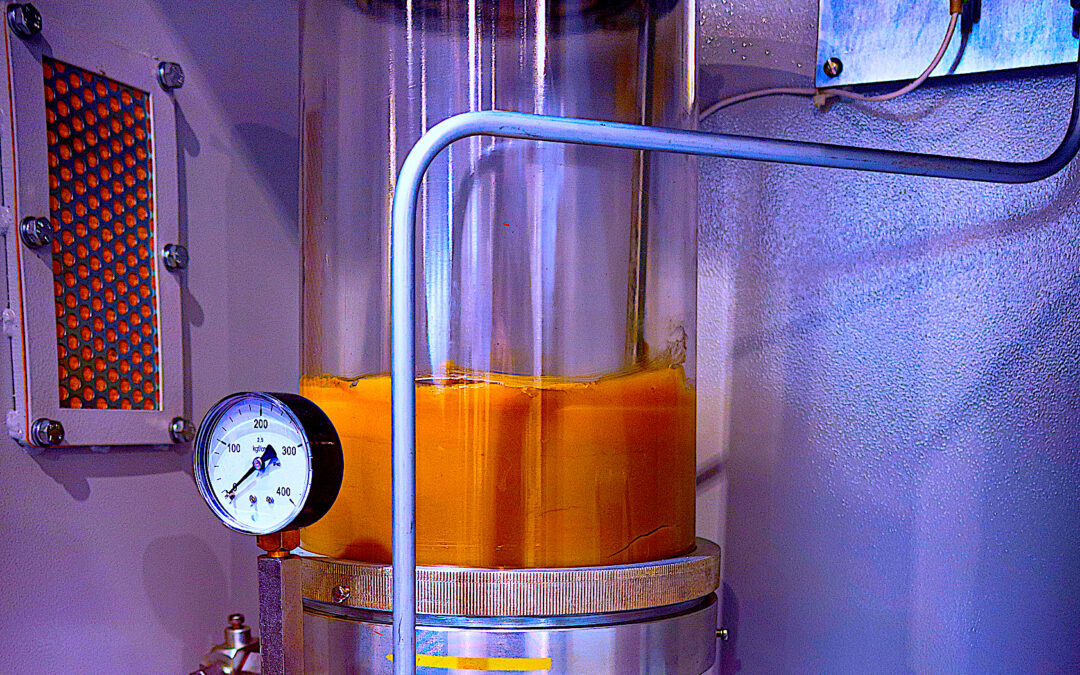

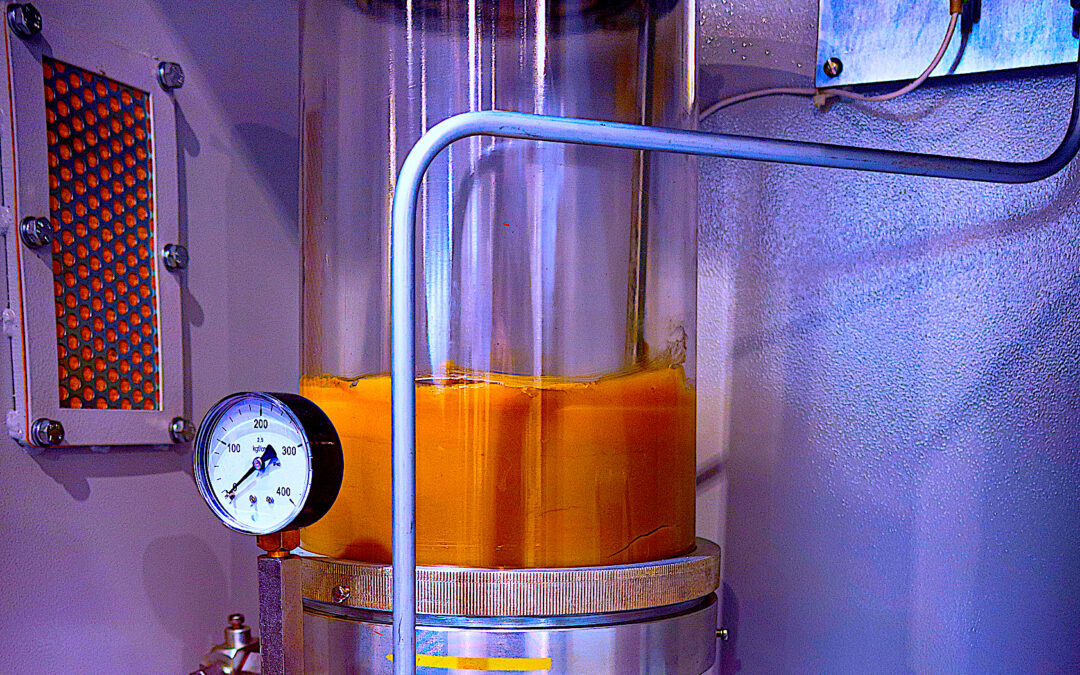

It is very easy to overlook the specialized needs of automated lubrication systems. In most asset-management-system and preventive-maintenance (PM) implementations, automated, centralized lubrication systems are often treated as integral components belonging to...

by Heinz Bloch, P.E., Editor | Jan 30, 2021 | Motors & Drives, RAM Tools & Methods, The Bloch Files

Reliability specialists are encouraged to make good use of industry standards. Well-written standards improve equipment uniformity and quality. Take, for example, standards from the National Electrical Manufacturers Association (NEMA). Their foreword explains scope...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 23, 2021 | Asset Management, RAM Tools & Methods

In the maintenance world, there are two types of inventory that must be managed. The first, which most people know as Maintenance, Repair and Overhaul (MRO), consists of spare or replacement parts. These items can be held on site in specialized physical inventory...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 17, 2021 | RAM Tools & Methods, Workforce Issues

What do COVID-19 recovery, robots, integrated automation systems, the Industrial Internet of Things (IIoT), RCM, re-shoring of jobs, and hiring talent have in common? Yes, they’re here, now, and they challenge many traditional ways of managing a business. But there’s...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Jan 16, 2021 | Asset Management, RAM Tools & Methods

The ultimate goal of the maintenance work management process is to ensure that the highest priorty jobs are executed effectively and on time to prevent functional failure of plant equipment. Achieving this goal requires that each of the serially connected...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 10, 2021 | Newsletter Column, RAM Tools & Methods

While driving my car several weeks ago, I felt a slight vibration in the steering wheel. I initially thought it might be due to snow buildup in one of the front wheels, but a visual check revealed clean wheels. During my next drive, though, the vibration became...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 9, 2021 | Maintenance Management, RAM Tools & Methods

“Procedure-based maintenance” will be invaluable in this era of growing skills shortages and the need for greater machine reliability. Machine complexity, coupled with the impact of the skills crisis and business needs for improved performance, has created a situation...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 3, 2021 | Asset Management, RAM Tools & Methods

A little over a year ago (Nov. 18, 2019), I wrote a newsletter column titled, “The Most Wonderful Time of Year” (see link below). In it, I highlighted how maintenance departments often go on shopping sprees with unspent budget dollars at the end of the...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 2, 2021 | Maintenance Management, RAM Tools & Methods

Many of the tens of thousands of preventive maintenance (PM) and repair work instructions I’ve reviewed over the decades have been sorely lacking in details. That means they’ve left a lot to the mechanics’ discretion. At the same time, many production...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Dec 5, 2020 | Asset Management, RAM Tools & Methods

At its core, reliability engineering is an analytical process. We’re the actuaries for the manufacturing-process industries. We analyze data to determine failure rates and mean times between/to failure (MTBF/MTTF) or mean time to repair (MTTR). We employ Weibull...