Many of the tens of thousands of preventive maintenance (PM) and repair work instructions I’ve reviewed over the decades have been sorely lacking in details. That means they’ve left a lot to the mechanics’ discretion. At the same time, many production departments have used “standardized work” (instructions) as part of their lean manufacturing process for years to drive out human errors. We also know that “procedure-based maintenance” can drive out errors and improve maintenance efficiency. So, the big question is how should we begin straightening out a PM program without getting mired down in a major documentation project?

FIRST THINGS FIRST

Your efforts should focus more on improving equipment performance and reliability than overhauling your PM work instruction documents. Be careful NOT to get tangled up in a massive rewrite or upgrade of all your facility’s PM work instructions—the financial justification might not be there. Concentrate on delivery of measurable business results every step of the way.

Let’s begin exploring a basic approach to develop and deploy PM work instructions. We’ll start by looking at three basic considerations when improving maintenance work instructions:

1. Focus on the most penalizing equipment.

2. Follow a structured developmental and deployment process.

3. Use a standardized document format.

#1. Focus on the most penalizing equipment.

Begin improving your maintenance work instructions by targeting your most penalizing equipment items or processes. Look beyond the maintenance needs of the equipment and consider the plant or facility operations. Select your starting points with equipment that’s a candidate for improved performance by asking a few questions:

♦ Do equipment problems often interrupt operations?

♦ Does the equipment create defects or off-spec conditions?

♦ Does the equipment cause sizeable delays in meeting customer requirements?

♦ Does the equipment seem to be environmentally sensitive and problem-prone?

♦ Do equipment damages or injuries occur during routine PM task completion?

♦ Are the PM work instructions sketchy, leaving much to the discretion of end users?

♦ Are they incomplete or not as efficient and effective as they should be?

♦ Do the results of the PM process vary with the person who performs the PM tasks?

The more “YES” answers to those questions, the more likely improved work instructions will be successful.

#2. Follow a structured developmental and deployment process.

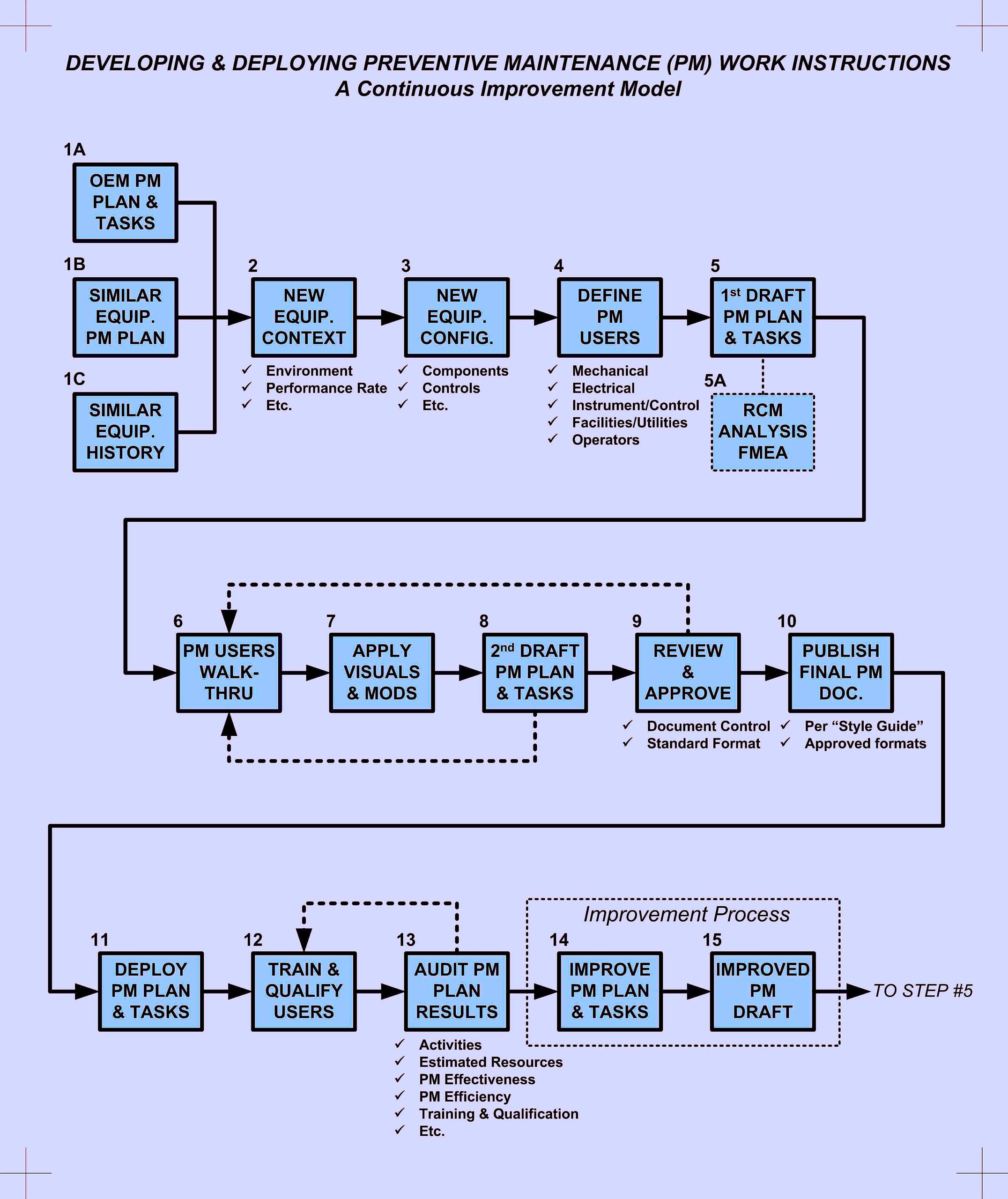

There may be as many ways to approach the development and deployment of maintenance work processes as there are writers. The challenge is to get started with one developmental model, improve it to suit your needs as you go, and then adopt it as a “standard.” I’ve found the continuous-improvement approach reflected in the accompanying process model (Fig. 1) to be especially effective in developing work instructions for NEW equipment.

Fig. 1. PM Work Instruction Model..

As you could imagine, each block in Fig. 1 can be interpreted differently. In an actual “Work Instruction Style Guide,” there would be detailed descriptions and procedures for each of the steps shown by blocks in the above model. Here are several items, albeit brief, to consider in each of the steps in Figure 1:

1A. Incorporate OEM recommendations for preventive maintenance whenever available.

1B. Build on the PM instructions of similar equipment (if available).

1C. Review work-order histories of similar equipment for PM effectiveness. Look for gaps.

2. Identify the specific operating conditions, operating/production requirements.

3. Review the equipment configuration. Verify common or non-standard components and modifications.

4. Identify those who will perform PM tasks, i.e., start of shift, end of shift, calendar, hourly, etc.

5. Engage a select end-user group to prepare a 1st DRAFT guided by a PM facilitator/engineer.

5A. If your plant is so inclined, use a formal RCM analysis or FMEA to define PM tasks.

6. Look for accuracy, gaps, and clarification during an actual “dry-run walk-through” of PM instructions.

7. Start applying visuals to the work instructions AND on the equipment for “maintainability.” Consider minor modifications to improve access, inspection, and overall ease of maintenance.

8. Compile the 2nd DRAFT PM Plan & Tasks. A repeat of the “dry-run walk-through” may be in order.

9. Submit for a formal review and approval process, per “management of change” (MOC) process.

10. Publish FINAL PM document according to approved standardized formats (See #3 below).

11. Deploy PM Plan & Tasks. This may involve updating the PM job plan in your CMMS/EAM and attaching the new work instructions to PM work orders.

12. Train and qualify users to accurately and completely follow the new work instructions.

13. Audit the PM performance to assure accuracy, efficiency and effectiveness of the instructions and the qualification of the persons using the instructions.

14. Over time, look for ways to improve the PM Plan & Tasks (work instructions).

15. Compile the improved PM Draft Work Instructions and return to Step #5 to complete update.

Regardless of which development-process model you use, be sure to document it. Then improve it.

#3. Use a standardized document format.

Some businesses may already have a standard document format for work instructions —many plants, however, do not. The following list summarizes major headings in a standard PM work-instruction format. Of course, the format should be adapted to the specific needs/requirements of YOUR facility. There are three major groups of information in this standard format: “Document Headings,” “Job Performance” and “Document Control.”

Document Headings. . .

1.0. Procedure Title & ID Number

2.0. Applicability: Location, Equipment, Process, Facility, Work Center, etc.

3.0. Procedure Identification: ID Number, Type

4.0. Frequency of Performance

5.0. Equipment Status: Running, Down, Major Shutdown/Turnaround

6.0. Introduction: Procedure Summary

Job Performance. . .

7.0. Responsibilities: (Who & What) Manager, Supervisor, Maintainer, Others

8.0. Assigned Personnel Requirements: Craft, Trade, Technician, Skill Level, Contractor…

9.0. Estimated Time: Hours, Duration, Number of People, Additional Work limits…

10.0. Personal Protective Equipment Requirements

11.0. Environmental & Safety: MSDS, Hazards, Confined Space, Cutting, Containment, Disposal…

12.0. Reference Documents & Source: OEM, Owner, Contactor…

13.0. Equipment & Tools Requirements

14.0. Parts Requirements

15.0. Materials & Supplies Requirements

16.0. Reference Documents

17.0. Procedure: Step-by-step, Should-Be and As-Found Readings, Graphics, Photos…

18.0. Comments: Job Notes, Work-Process Revisions

19.0. Completion Signatures: Performed By, Approved By, Inspected by, …

Document Control. . .

20.0. Current Revision: Revision Number & Date

21.0. Document Control Identification

22.0. Document Originator & Approval: Name, Contact Information, Effective Date…

SOME FINAL THOUGHTS

There are several options for using detailed PM work instructions: They could be attached to PM work orders when they’re distributed; made available in hard copy at the equipment or point of use; or posted on a network computer terminal that’s accessible to the person performing the tasks. The work instructions can also be summarized in checklist format for ease of use on the job if the tasks to be performed are not particularly complex or critical.

Remember: Detailed maintenance work instructions are meant to drive out the natural “human variation” in the way people do things. They provide a basis for training and qualifying a person to perform the required tasks on specific equipment. But the use of the work instructions must be enforced—they’re not optional. Instructions that are developed in the manner described here are a starting point for continuous improvement of equipment performance and reliability, improved workplace safety and environmental conditions, as well for improving overall productivity of a company’s physical assets AND its human resources.

Part II of this series (next week), we will explore the ins and outs of procedure-writing and include some actual examples along with a number of different work instruction layouts and summary checklists.TRR

Editor’s Note: Click The Following Link To Read

“Detailed Maintenance Work Instructions (Part I): Why Use ‘Em?” (Dec. 20, 2020)

ABOUT THE AUTHOR

Bob Williamson is a long-time contributor to the people-side of the world-class-maintenance and manufacturing body of knowledge across dozens of industry types. His background in maintenance, machine and tool design, and teaching has positioned his work with over 500 companies and plants, facilities, and equipment-oriented organizations. Contact him directly at 512-800-6031 or bwilliamson@theramreview.com.

Tags: reliability, availability, maintenance, RAM, operator care, maintenance management, plant operations, workforce issues, training and qualification