It is very easy to overlook the specialized needs of automated lubrication systems. In most asset-management-system and preventive-maintenance (PM) implementations, automated, centralized lubrication systems are often treated as integral components belonging to the host machine. They’re not considered to be separate assets. This lack of asset recognition often results in a detrimental “fill and forget” attitude toward the lubrication system that can quickly lead to early machine and lube-system demise.

Lubrication is the lifeblood of all machines. It is easy to draw a direct parallel between a machine lubrication system and a human body’s circulatory system. When the heart, or pump, becomes diseased or dies, the body’s lifecycle shortens significantly. When the blood becomes contaminated, the organs/components it serves, immediately begin to suffer and wear out. When blood leaks from its lines, the body can cease to operate in minutes.

As humans, we have little trouble recognizing the importance of the circulatory system to our bodies’ well-being, reliability, availability, and ability to perform at their best. Accordingly, most of us consider our circulatory systems to be unique assets that deserve specialized attention. We can, similarly, use our understanding of such systems to shed light on the importance of treating a machine’s lubrication, or circulatory lifeblood system, as a separate asset that also deserves specialized attention.

IT’S TIME FOR A TUNE-UP

Once a lubrication system is designed, installed, and commissioned, its rates of lubricant usage and delivery to individual bearings are rarely checked. In many plants, the most attention a lube system can expect is to have its reservoir filled and, every now and then, its filter changed. When performing lubrication program audits, this type of finding is typical. Other typical findings include, but aren’t limited to missing fill caps and breathers; dirt- and debris-covered reservoirs, lines and bearing points; over-lubricated bearings; and lubricant line and fitting leaks and spills.

Correctly designed, tuned, and maintained centralized lubrication systems are proven to triple the life cycle of a bearing when compared to a sporadic, manual lubrication approach. Keeping lubrication systems and associated machinery in optimal condition, begins with recognition and adoption of the following best practices:

- Treat your lubrication systems as assets, or child assets of their parent machines within your asset-management program. Develop and individualize a tailored PM program for each lubrication system.

- Map out your lubrication system schematically. Physically identify each bearing point; metering point; primary feed line(s) and secondary feed lines by number for ease of troubleshooting. Perform a heat signature baseline inspection of each bearing point using an Infrared thermometer or infrared thermography gun. This is best performed when the machine is running (whenever possible), or just after shutdown. Document individual bearing temperatures on the schematic map.

- Mixing of lubricants can have a devastating effect on bearings. Clearly mark/label each lubricant reservoir with its correct lubricant name, manufacturer/supplier, and viscosity. Only fill with transfer equipment dedicated for use with the named lubricant. This may mean you will require a one-time purchase of multiple standardized, transfer pumps that are color-coded, as well as labeled, according to their respective assigned lubricants.

- Physically tether all reservoir fill ports caps, drain caps, and the like., with locking wire to ensure they cannot be misplaced or lost.

- Replace all breathers with visual-indicator desiccant breathers. (Color changes indicate when the breather requires replacing).

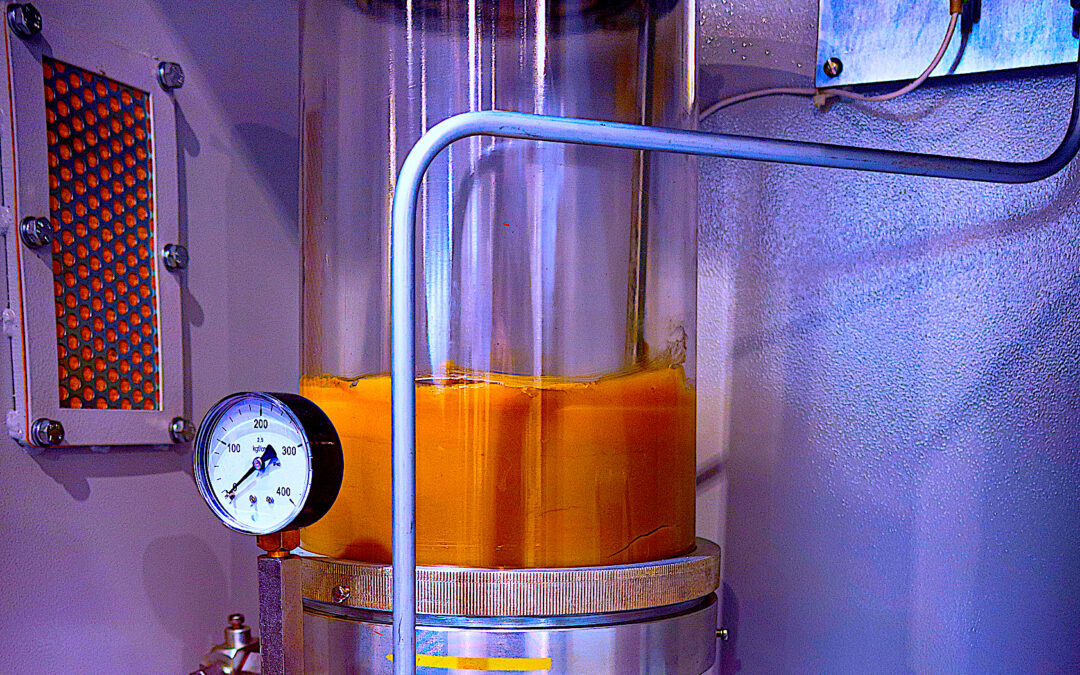

- Install engineered placement of external sight glasses and oil-analysis test sampling points on all recirculating oil systems.

- Automated lubrication pumps and their associated metering devices are engineered and built with very close tolerances. By de facto, they are NOT dirt tolerant. A simple 5-micron piece of dirt can easily score a piston and bore surface, then move on to cut and damage a fluid seal that eventually will result in system wear and lubricant leakage. (To give perspective, a human hair is 70 microns in diameter). Put in place a regular external and internal cleaning strategy to ensure no dirt or water contamination is inadvertently transferred into the reservoir when filling with lubricant.

- If a lubrication system is displaying a faulty metering valve or block, do not repair it; always replace with the same-sized valve or block. Progressive divider metering blocks are built with hydraulic spool valves that are individually fitted and are not interchangeable. Single-line-resistance systems employ metering or control units that are not designed to be repairable or “drilled” out. It’s easier and less expensive to replace the entire metering block or unit rather than take these items apart and repair them.

- System reservoirs are often found empty with low warning devices disconnected. To ensure reservoir levels can be seen, do NOT paint the see-through reservoir or sight-glass level indicators. Mark the reservoir with a RAG (Red/Amber/Green) indicator system in which the Green level indicates the high-fill line; Amber level indicates the early-warning fill requirement; and the Red level indicates the final-warning fill requirement before the system shuts down. Operators are trained to observe the fluid level and notify maintenance once the Amber level is reached; if the unit is not filled prior to reaching the Red-level indicator, maintenance is once again notified for the unit to be filled. If low-level alarms are employed and disconnected, the units must be protected with a physical shroud.

- Develop a reservoir fill log to plot and monitor system usage.

- If a lockout procedure is required to fill the unit reservoir, system maintenance may not take place when production is in progress. Moving the system reservoir and control outside of the equipment lockout perimeter will allow the unit to be maintained and filled while the equipment is running.

- Train operators to recognize faults and perform regular inspections for system damage. Neglect of warning devices will rapidly shut down a lube system and place bearings at great risk.

- Regularly test and “tune in” your lubrication system. This is best achieved by performing a sensory check of each bearing point using the machine’s lubrication mapping schematic and following a simple 10-step method, as shown below::

1. Review any recent vibration-reading-trend reports, infrared -heat-signature reports, and oil-analysis reports that pinpoint any unusual bearing problems.

2. Consult with the machine operator to discuss and locate any recent unusual noises, vibration, smells, or signs of smoke or leaks, and re-confirm with predictive-maintenance (PdM) reports.

3. Perform a visual inspection of each lube point to ensure there is no physical evidence of over-lubrication (lubricant running out of the bearing past the shield or seal).

4. Perform a heat-signature inspection of each bearing point using an infrared (IR) thermometer or thermography gun. This is best performed when the machine is running whenever possible, or just after shutdown. Compare findings against baseline bearing temperatures on schematic map and any anomalies found in steps one through three above. Individual temperature spikes denote a single bearing-metering problem, while global spikes denote a system-pump- delivery sequence/timing issue. Note: Bearing temperatures vary depending application and environment, but generally should run up to 180 F with standard non-synthetic lubricants.

5. All single-line-resistance, fixed-injector, or progressive-divider type lubrication systems will have been pre-engineered by the system vendor prior to purchase and should only require the pump output delivery and sequence timer to be tuned. Once tuned in, write down the settings and place inside the sequence controller. Always check to ensure the original timer settings noted have not been changed.

6. If the lubrication system is a variable-output, single-line or dual-line injector type, the end-user is responsible for tuning the pump-delivery output, sequence timer, and each delivery-point output. This system type is vulnerable to over-lubrication, due to end-user interference changing delivery-point outputs. Once tuned, physically scribe the injector set-point mark, then write down the settings and place inside the sequence controller. Check to ensure settings are unchanged. If changed, consider placing a physical tamperproof guard over the injector points.

7. Check line integrity for kinks or breaks and work-hardening points at bends. Check hoses for abrasive wear, splits or signs of seepage. Replace (and document) all problem line and hoses immediately. If blocked line or broken line indicators are employed, ensure operators are trained to recognize when they are in fault mode and be able to take the appropriate action.

8. Inspect the oil-filtration/change log for troubling trends in need of further investigation.

9. Inspect the lubricant-fill log for troubling trends in need of further investigation. If a usage spike is found, check for hidden system leaks.

10. If possible, perform a before/after machine-energy-draw analysis under operating load to determine and prepare an economic and environmental impact/improvement report.

WORDS TO THE WISE

When site personnel realize how important a well-tuned lubrication system is, the system becomes a true asset to its host machine, the organization, and the environment. Scheduling time sooner than later to tune up this equipment can lead to significant payback in the plant.TRR

ABOUT THE AUTHOR

Ken Bannister has 40+ years of experience in the RAM industry. For the past 30, he’s been a Managing Partner and Principal Asset Management Consultant with Engtech industries Inc., where he has specialized in helping clients implement best-practice asset-management programs worldwide. A founding member and past director of the Plant Engineering and Maintenance Association of Canada, he is the author of several books, including three on lubrication, one on predictive maintenance, and one on energy reduction strategies, and is currently writing one on planning and scheduling. Contact him directly at 519-469-9173 or kbannister@theramreview.com.

Tags: reliability, availability, maintenance, RAM, lubrication, automated lubrication systems, bearings, oil, grease, infrared thermometers, infrared heat guns, infrared thermography, sight glasses, breathers, oil analysis