by Heinz Bloch, P.E., Editor | Nov 1, 2020 | Newsletter Column, Plant Operations, The Bloch Files

If your plant depends on a dedicated group of reliability professionals to first collect and then analyze machinery vibration and other equipment-condition data, you’re not alone. They’re probably assigned to this task because your organization knows that an...

by Heinz Bloch, P.E., Editor | Oct 23, 2020 | Asset Management, Plant Operations, The Bloch Files

Since the mid-1980s, a fair number of compressor users have taken another look at piston rod wear. With sophisticated coatings finding widespread acceptance in aerospace and gas turbine applications, it was only a matter of time before a number of coating types...

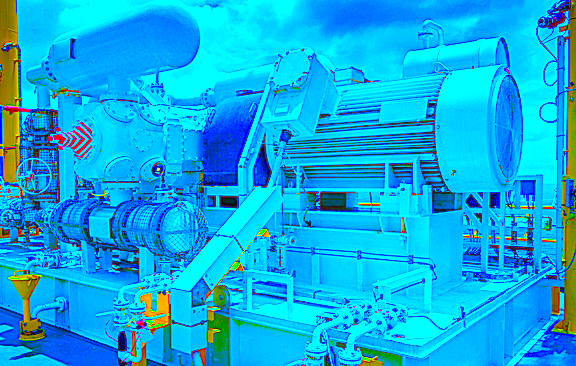

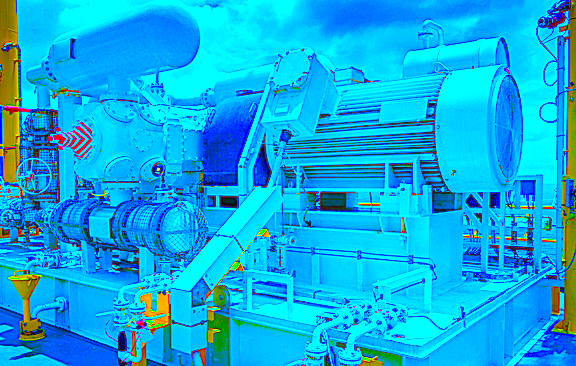

by Heinz Bloch, P.E., Editor | Oct 17, 2020 | Asset Management, Plant Operations, The Bloch Files

Equipment purchasers are always interested in meeting the cost and schedule targets for projects. There could, however, be conflicting goals when purchasing drivers and/or auxiliaries from vendors other than the primary fluid-machinery manufacturer. While cost targets...

by Heinz Bloch, P.E., Editor | Oct 10, 2020 | Learning from Mistakes, Plant Operations

At a gathering of reliability professionals in Texas, the coordinator invited questions from the audience. I was asked what I thought of installing flexible piping, joints, or connectors on centrifugal pumps. My answer was relatively short and specific. I’ve...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Oct 3, 2020 | Plant Operations, RAM Tools & Methods, RAM's Human Factor, Workforce Issues

I have written extensively in The RAM Review about the importance of precision-work instructions to ensure high-quality maintenance work. Such instructions are particularly valuable for bringing in a successful shutdown, turnaround, or outage (STO) event. The...

by Heinz Bloch, P.E., Editor | Sep 26, 2020 | Plant Operations, RAM Tools & Methods, The Bloch Files

We’re using this space to wrap up our short series on the importance of machinery-quality assessments (MQAs) that began on Sept. 4, 2020 (see list of previous articles below). The overall message: MQAs can be an important tool for those seeking to zero in on...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Sep 20, 2020 | Asset Management, Newsletter Column, Plant Operations

Those who have attended one of my workshops on various aspects of reliability engineering and management, or have seen me present at conferences, may have heard me say, “Data is the difference between deciding and guessing.” It’s a slogan I’ve used for at...

by Heinz Bloch, P.E., Editor | Sep 17, 2020 | Plant Operations, RAM Tools & Methods, The Bloch Files

This technical note on seal-flush plans is part of my series on machinery-quality assessments (MQAs) for The RAM Review. It’s a follow-up to the most recent article in that series, “An MQA Approach to Seals and Flush Plans” (Sept. 12, 2020)....

by Heinz Bloch, P.E., Editor | Sep 12, 2020 | Plant Operations, RAM Tools & Methods, The Bloch Files

This article is based on a real-world situation related to to my recent article (Sept. 4, 2020) on the value of machinery-quality assessments (MQAs) in selecting best-available technologies for plant applications. Here, I discuss how a former manager’s feedback...

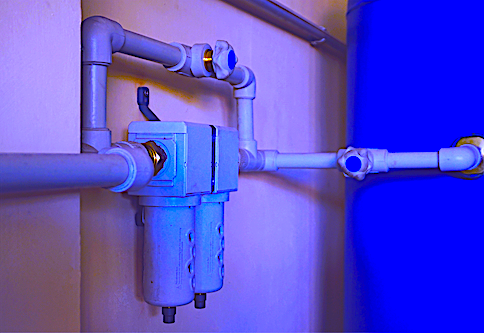

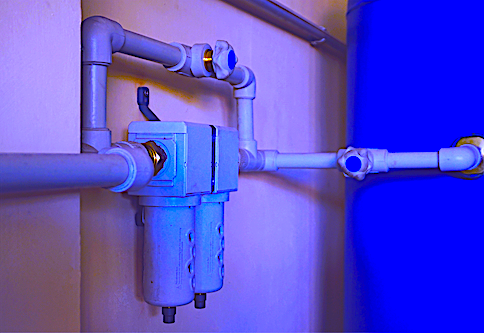

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Sep 11, 2020 | Plant Operations, Safety Matters

Why is it that many people on the plant floor use compressed air to clean their machines and the floors around them? It’s easy. That’s why. The problem is compressed air can be the most expensive and most ineffective and damaging way to “clean” machine♦s. Think about...