Equipment purchasers are always interested in meeting the cost and schedule targets for projects. There could, however, be conflicting goals when purchasing drivers and/or auxiliaries from vendors other than the primary fluid-machinery manufacturer. While cost targets might initially be met, missed schedules and future warranty disputes present risks that must be considered. Using compressors as an example, it’s worth noting how experienced owner-operators avoid these types of conflicts.

AGREEMENT ON ‘TRAIN RESPONSIBILITY’

Whenever Best-in-Class (BiC) companies separate the procurement of a major fluid machine from the procurement of its driver, one of the two suppliers is given train responsibility. The owner-operator (purchaser/end-user) then pays the responsible vendor (usually the major pump or compressor manufacturer) a modest, but equitable, sum for accepting single-point train responsibility. Although this practice dates back quite a few years, some choose not to follow it.

For example, when the common-sense, single-point rule was disregarded by an over-zealous project manager at a company that usually prided itself as a sophisticated BiC performer, plenty of unproductive finger-pointing resulted. Later, the issue received renewed attention during a performance appraisal: The project manager’s employer-boss considered it a career-limiting oversight to not assign single-point responsibility for critical compressor trains.

Note that the monetary savings of buying the driver from a detached bidder often vanish when a single additional startup-delay day results from dividing responsibilities. While faulty automobile tires are usually handled by the tire manufacturer, similar separations are not advisable for drivers and driven machines.

EXCEPTIONS TO THE RULE

Of course, giving a vendor single-point responsibility does not mean that all risk has been removed. As a case in point, I recall some reciprocating compressors purchased from a manufacturer that had recently acquired another company’s product line. Unfortunately, the purchaser/end-user operation quickly encountered glitches in spare-parts identification and timely availability of spares.

In a second instance, a manufacturer of reciprocating-compressor frames and main running gear (crankshafts) tried to adapt another vendor’s pistons and cylinders. Thus, part of the assembled machine originated as subassemblies for high-speed compressors; the rest of the machine consisted of API 618-compliant slow-speed subassemblies. That “marriage” went through a significant rough spell early on.

Initially, there was much consternation as to who was at fault when the compressors suffered from insufficient capacity and different components started to break. Shortly thereafter, those hybrid machines were installed on a floating production/storage/ offloading unit (commonly called FPSO), and things really went wrong. The owner-purchaser initiated litigation against as many parties as possible, and years were wasted in tedious and contentious arguments. It’s good to know, however, that all issues were eventually resolved.

Regrettably, many interesting failure experiences and relevant failure-avoidance steps are frequently hidden from our view. Litigants often sign protective non-disclosure agreements because neither side wants their reputation blemished. All involved are reluctant to publish detailed articles or papers about these events, and lessons learned turn into lessons forgotten.

FOCUSING ON THE BRIGHT SIDE

In contrast, much less risk exists when a purchaser opts for entire machinery trains from top-of-the-line manufacturers. Such manufacturers would have a proven record of long-term quality and as-promised performance. A case in point concerns modern process-compressor packages that are built in accordance with applicable portions of the different API standards; some are covering integrally-geared centrifugal to meet the demands of the Petroleum, Chemical, Power and Gas Industries (API-617).

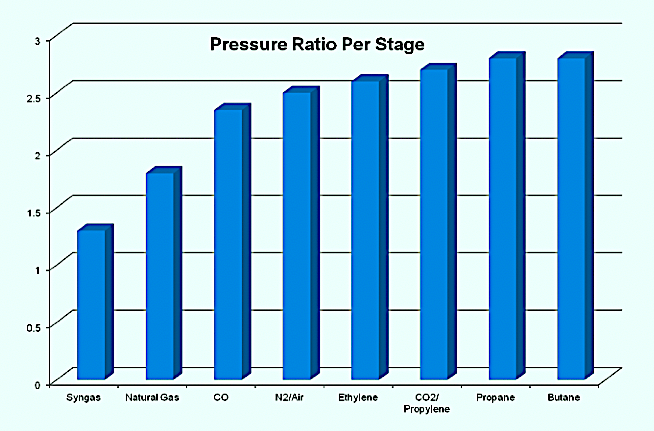

To date, these types of integrally geared compressors have been built for a wide range of services, including gas-turbine-fuel gas (methane), hydrocarbon refrigeration gases, ammonia, carbon monoxide, carbon dioxide, syngas, gas-field gathering, and others. In the past, these types of compressors might have been somewhat smallish machines. Today, however, we see flow rates ranging to 400,000 m^3/h; molecular weights from 6.5 to 58 MW; stage-pressure ratios as high as 2.6:1 (Fig. 1); inlet pressures from ambient to 45 bar; and discharge pressures to 200 bar.

Fig. 1. Achievable per-stage-pressure ratios are mole-weight dependent. (Source: Cameron, Buffalo, NY)

One U.S. manufacturer has designed integrally geared compressors for drivers up to 20,000 kW. This OEM and/or its predecessor companies have produced 12,000 such machines (similar to that shown in Fig. 2), with six high-speed stages available in a single integrally gear-driven frame (casing). However, as many as 12 stages have been incorporated in an integrally geared compressor designed by a European manufacturer, and drivers have, on occasion, become considerably larger than 20,000 kW. (In fact, machines applied in phthalic anhydride units have exceeded 37,000 kW.)

Fig. 2. A modern, integrally geared compressor. (Source, Cooper, Buffalo, NY)

Today’s compressor efficiencies can approach 90%. Some manufacturers have designed and built their own gearboxes for decades. Many producer factories have undergone expansions over the past 50 years. The products they manufacture are extensively shop-tested, and the overall designs are always fully up-to-date. Seal designs have kept pace with modern dry-gas-sealing technology, as have their well-proven intercoolers.

In any event, there are many opportunities to use multi-stage, integrally geared machines where mere tradition may have steered us in the direction of positive-displacement machines. The design of these late-generation, dynamic compressors overwhelmingly favors single-point responsibility. As an additional feature, modern, integrally driven compressors often represent the best possible blend of standardization and customized design. These machines certainly merit consideration and invite comparisons with every other type of compression machinery.

BOTTOM LINE

We’ve highlighted integrally geared compressors here because they are representative of prototypical single-source machines. Drivers, sealing and lubrication systems may, perhaps, be provided by different vendors, but the responsibility stays with the compressor manufacturer, and the package is “single-sourced.”TRR

Editor’s Note: Click Here To Download A Complete List Of Heinz Bloch’s 22 Books

ABOUT THE AUTHOR

Heinz Bloch’s long professional career included assignments as Exxon Chemical’s Regional Machinery Specialist for the United States. A recognized subject-matter-expert on plant equipment and failure avoidance, he is the author of numerous books and articles, and continues to present at technical conferences around the world. Bloch holds B.S. and M.S. degrees in Mechanical Engineering and is an ASME Life Fellow. These days, he’s based near Houston, TX. Email him at heinzpbloch@gmail.com.

Tags: reliability, availability, maintenance, RAM, fluid handling, pumps compressors, asset management