This technical note on seal-flush plans is part of my series on machinery-quality assessments (MQAs) for The RAM Review. It’s a follow-up to the most recent article in that series, “An MQA Approach to Seals and Flush Plans” (Sept. 12, 2020).

Mechanical seals represent critically important components in all fluid machines. In pumps there are many different seal categories. There are well over a thousand different fluids to be sealed and fluid temperatures range from deep cryogenic (minus 150 degrees C) to unusually hot, perhaps 420 degrees C. Mechanical seal selection makes a compelling case for involving vendors giving you access to application engineers instead of steering you to salespersons working on a commission basis.

Application engineers would be able to point out advantageous flush plans and will work with end users to find optimized solutions. The sealing components must be good for the operating temperature and a suitable flush liquid must be introduced for cooling the shaft and its seals. However, large amounts of flush liquid can be expensive and using a refined product coming from another pump or process unit in the plant may not be to the user plant’s advantage.

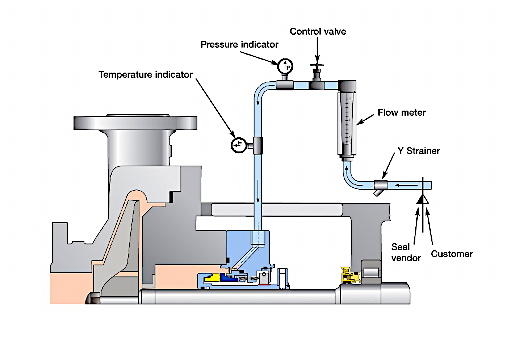

Note how the liquid is routed in Flush Plan 32. After it has done its cooling and lubricating duty (Fig. 1), it passes through the pump’s throat bushing into the much less valuable pumped fluid. In slurry and light-cycle services, reliability professionals must establish the true cost of Plan 32, regardless of its simplicity, low initial cost, and overall popularity. Relatively large quantities of clean externally-supplied flush liquid end up in the light slurry being pumped.

Fig. 1. Injection of cool or clean liquid from external source into the seal chamber per API Plan 32.

Fig. 1. Injection of cool or clean liquid from external source into the seal chamber per API Plan 32.

(Source: AESSEAL, Inc.)

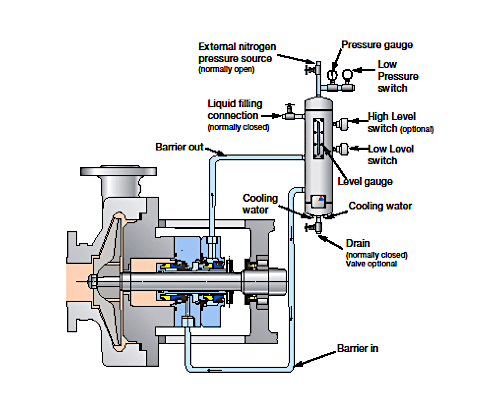

In an email exchange with the author, the former manager of a Caribbean oil refinery recalled that due to widespread use of several presumably “inexpensive” Plan 32 flush systems at that location, an estimated 1,500 bpd (barrels per day) of a refined product (gas oil) were returned into an unrefined product stream. Switching to a dual-seal and API Plan 53A (shown below in Fig. 2) resulted in very substantial savings and rapid payback.TRR

Fig. 2. API Plan 53A: Pressurized barrier fluid circulation in outboard seal of a dual seal configuration.

Fig. 2. API Plan 53A: Pressurized barrier fluid circulation in outboard seal of a dual seal configuration.

A pumping ring maintains circulation while running; thermosiphon action provides some cooling at standstill.

(Source: AESSEAL, Inc.)

EDITOR’S NOTES:

Click On The Following Links For MQA-Related Articles

“Zero in On Best Available Technology MQA” (Sept. 4, 2020)

“An MQA Approach to Seals and Flush Plans” (Sept. 12, 2020)

Editor’s Note: Click Here To Download A Complete List Of Heinz Bloch’s 22 Books

ABOUT THE AUTHOR

Heinz Bloch’s long professional career included assignments as Exxon Chemical’s Regional Machinery Specialist for the United States. A recognized subject-matter-expert on plant equipment and failure avoidance, he is the author of numerous books and articles, and continues to present at technical conferences around the world. Bloch holds B.S. and M.S. degrees in Mechanical Engineering and is an ASME Life Fellow. These days, he’s based near Houston, TX. Email him at heinzpbloch@gmail.com.

Tags: reliability, availability, maintenance, RAM, machine-quality assessments, mechanical seals, seal-flush plans