Industry Has Lost A Giant, We Have Lost A Friend. R.I.P. Heinz Bloch

It is with a great deal of sadness that we report the recent passing of our wonderful fellow editor and long-time mentor to so many throughout industry around the world: Heinz Bloch’s wisdom (and wit) will be sorely missed.

NASCAR Racing: A Real-World Model For Lean Equipment Management Principles

Some have called NASCAR’s pit crews the “rock stars” of the racing world. And rightfully so. For these team members, the race for the green flag is just as important as the race for the checkered one.

Think Bottom-Line Reliability: Optimizing Your Equipment Lubrication

When manufacturers of plant equipment have no interest in upgrading the reliability of their products, it’s up to end-users or owner-purchasers to demand better performance. Does your operation have such specs?

Part V: More Thoughts On Electrical Reliability (Specifically, The Missing Data)

For on-site power-system surveys, the type of information needed and how it relates to the investigation is paramount. Be it gathered data or anecdotal, it must boost the understanding of any electrical issues.

Customer Success Story: How A 7-Step ‘Pit-Stop’ Approach Increased High-Margin Production

Concepts that apply to managing large, multi-week, multi-million-dollar STOs also can be applied to 2- to 3-day wash events. The Texas chemical manufacturer in this story quickly saw payoff from this approach.

Lean Equipment Management: How To Put Its 7 Principles To Work (Part 6, ‘The Benefits’)

Despite the “manufacturing” theme in this series, it’s important to note deployment of these principles is just as beneficial in mining, oil & gas production, petrochemical, facility utilities, and public utilities.

Part IV, More Thoughts on Electrical Reliability (Specifically, Is Your Electricity Clean?)

What’s the state of the electrical power system at your site? Are you looking at a feel-good romance or, maybe, a campfire horror story? And how can you tell the difference? The author offers tips.

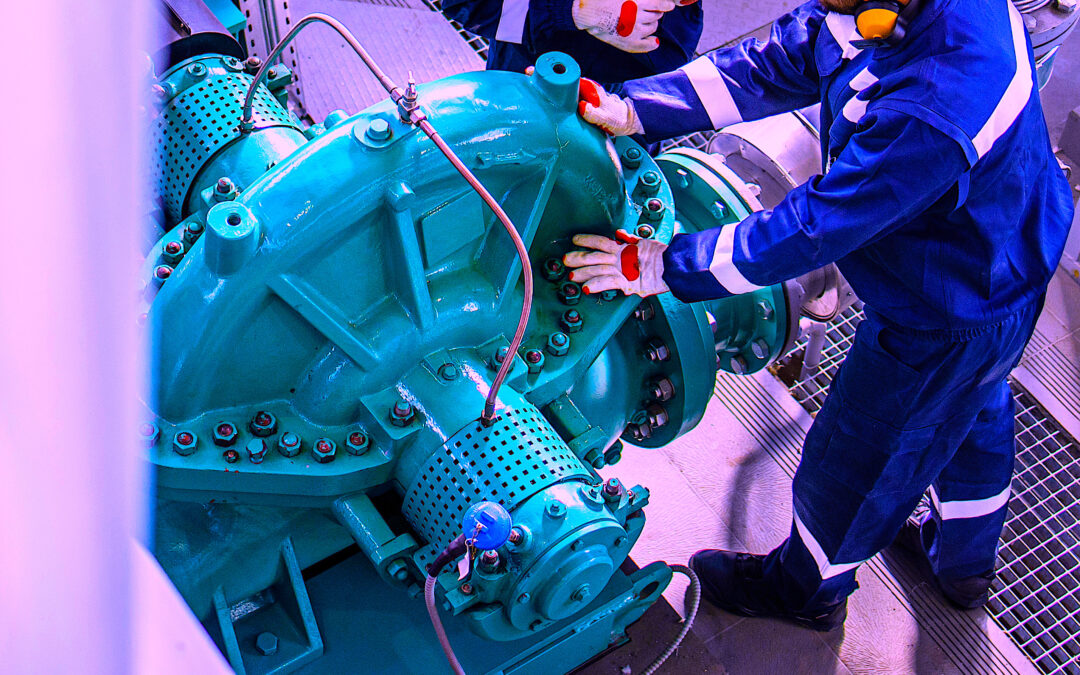

Examining Reliability-Compromised Process Pumps

The author has said it before: Reliability suffers when best-available technology isn’t used. Intelligent upgrading would reduce maintenance labor and improve the safety and reliability of many plants.

Lean Equipment Management: How To Put Its 7 Principles To Work (Part 5)

This week’s column focuses on building a lean equipment management culture. In doing so, the discussion points to one of the most enduring examples of that approach: The Toyota Production System.

Urgently Needed: Effective Rebuilding And Upgrading

Beware. Some pump repair and rebuild shops focus solely on keeping costs low. They often can’t offer the engineered solutions needed for best efficiency, lowest life-cycle cost, and longest pump life.