This article continues a multi-part discussion on research conducted by EPRI (Electric Power Research Institute) and IEEE (Institute of Electrical and Electronics Engineers). As noted in the two previous installments of this series (see links at the end of this article), the studies from the two groups provided similar data based upon failure rates. Since it can be assumed that the variations in failure rates and reliability of machines by facility in the EPRI research related to the level of maintenance involved, here we’ll be focusing on information from the IEEE studies. Note that the information is broken down by size, enclosure, and speed, thus showing the importance of maintenance practices on large machines.

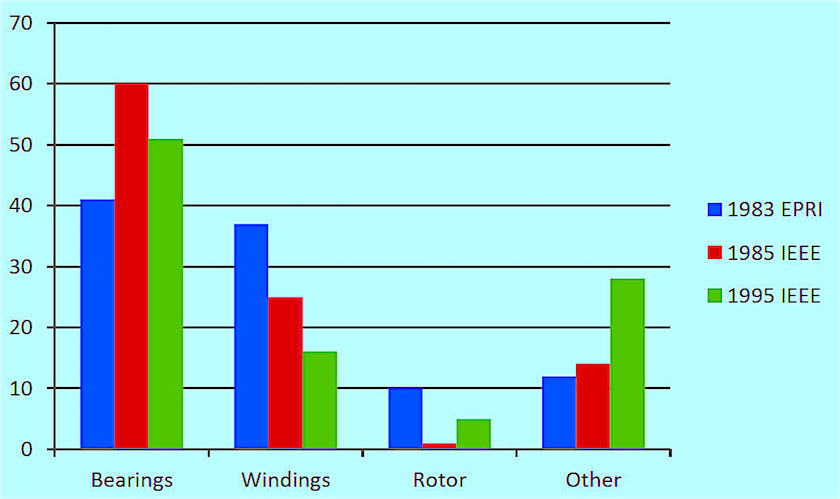

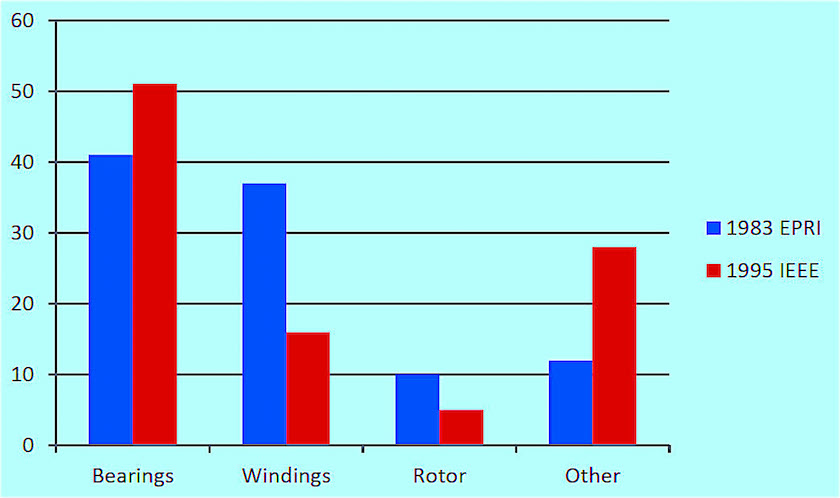

The primary difference is identified in Fig. 1, where the various faults found in the machines were significantly different. It is noted that the EPRI study focused on utility motors 100 hp and larger, while the IEEE study related to machines of 10kW (~15 hp) and larger, at 50Hz and 60Hz.

Fig. 1. Comparison of 1983 EPRI survey to 1995 IEEE survey.

As shown in Fig. 2, the actual failure modes for each industry group were significantly different, other than a similar pattern. A majority of faults were represented as bearings, followed by windings as the second cause, then the rotor, then all other faults combined. The 1985 IEEE survey covered industrial and commercial facilities, while the 1983 EPRI study covered utilities only, and the 1995 IEEE survey covered petrochemical and similar industries. Other significant differences with the 1985 survey are that it covered machines from 200 hp to 10,000 hp, voltages to 13.8kV, and induction, synchronous, wound-rotor, and DC motors.

Fig. 2. Comparison of the 1983 EPRI and the 1985 aand 1995 IEEE surveys.

As shown in Fig. 2, the actual failure modes for each industry group were significantly different, other than a similar pattern. A majority of faults were represented as bearings, followed by windings as the second cause, then the rotor, then all other faults combined. The 1985 IEEE survey covered industrial and commercial facilities, while the 1983 EPRI study covered utilities only, and the 1995 IEEE survey covered petrochemical and similar industries. Other significant differences with the 1985 survey are that it covered machines from 200 hp to 10,000 hp, voltages to 13.8kV, and induction, synchronous, wound-rotor, and DC motors.

Based upon the breadth of industries covered, we will review the following data as it relates to the 1985 IEEE survey and machines over 1000 Volts. From an overall industry standpoint, 2300 and 4160 Vac machines had a median failure rate of 0.0714 FPU (Failures Per Unit per Year) for induction motors, 0.0762 FPU for synchronous motors, and 0.0319 FPU for wound rotor motors.

If we further break down the information from the survey, motors from 500 hp to 5000 hp had a median failure rate of 0.0730 FPU and from 5001 hp to 10,000 hp a median failure rate of 0.2169 FPU. In relation to motor speed and failure rate: 0-720 RPM is 0.1004 FPU; from 721-1800 RPM is 0.721 FPU; and, 1801-3600 RPM is 0.519 FPU. In effect, larger, slower speed motors have a higher failure rate, with most machines being induction and synchronous motors in the survey. The wound rotor motors covered tended to be smaller horsepower.

Based upon the IEEE studies, the use of continuous monitoring, such as temperature and vibration, can reduce the failure rate by one-third, assuming action is taken to mitigate problems and repeat failures. None of the studies has identified the effect of the use of partial-discharge testing on machines over 6000 Vac and continuous or periodic electrical- or current-signature analysis. However, it can be assumed, and will be addressed in the next article, that such practices and technologies are, in most cases, used for fault detection rather than winding protection. Does this have an impact?

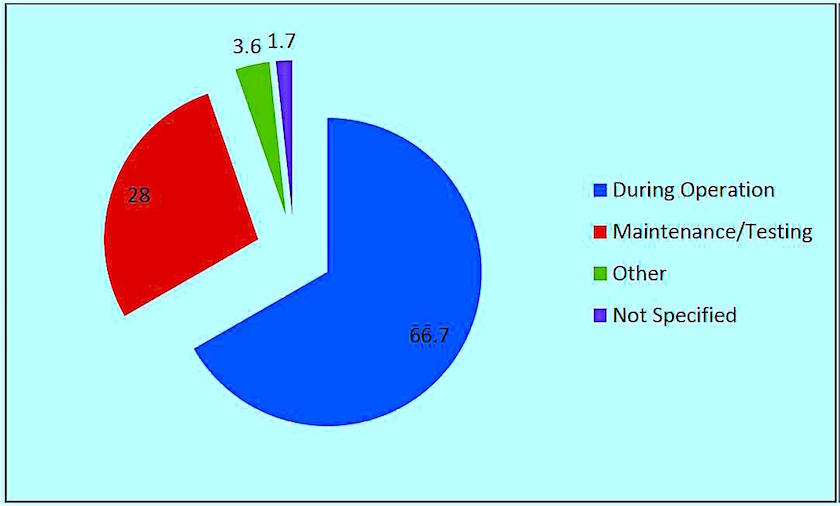

The IEEE studies identify the number of faults that are detected by a variety of technologies and maintenance practices and the median downtime hours by failure based upon the fault being detected as part of a maintenance practice or during operation. According to the 1985 IEEE survey, the failures were detected as shown in Fig. 3.

Fig. 3. When failures were detected or discovered.

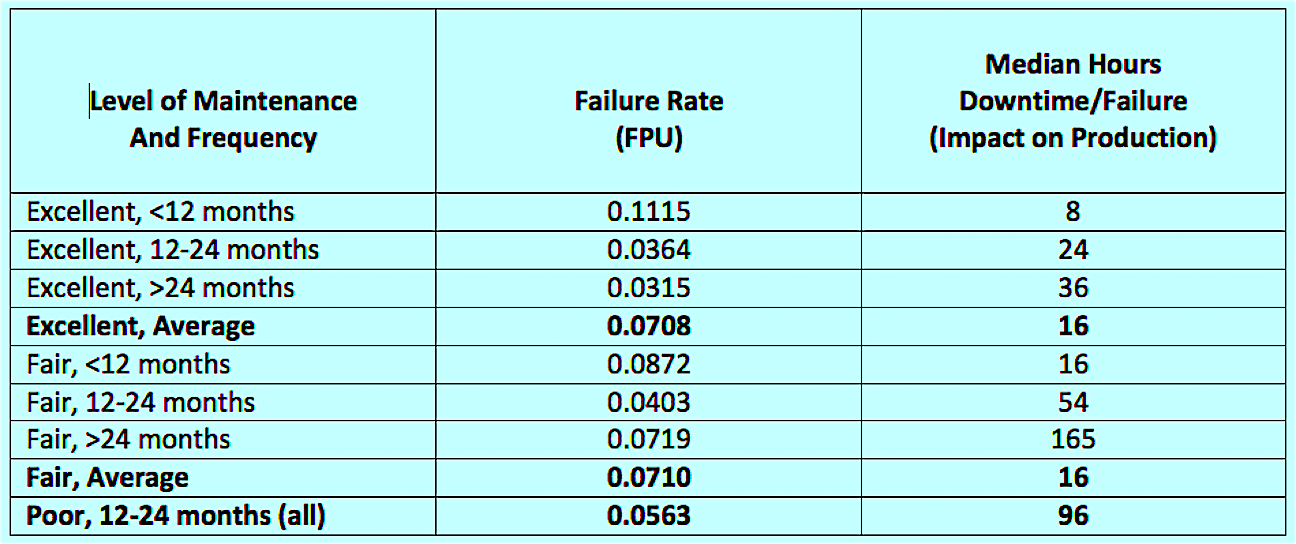

The level of a maintenance program and frequency of maintenance practices also had a significant impact not just on the failure rate, but also on the median hours of downtime per failure (Table 1).

Table I. Maintenance Frequency and Type vs. Failure Rate (FPU)

The practices that encompassed “excellent: maintenance included:

- visual inspections

- insulation resistance

- cleaning

- lubrication and/or filters;

- vibration analysis

- bearing check/inspection

- ampere and temperature tracking

- air-gap checks

- alignment

- check/change brushes, as applicable.

In Table I, the excellent <12 months that showed the highest FPU was the result of how few machines were being evaluated, as noted in the study, and an unexpected failure occurred. Another explanation of the higher failure rate and lower associated production average disruption was that potential faults were detected as part of the maintenance practice and addressed prior to failure versus unplanned and unexpected failures that resulted in higher downtime.

In the next installment of this series, we will cover some notes related to the FPU and failure modes that change the entire landscape of the EPRI and IEEE studies and our resulting perceptions. We’ll then cover some more-recent studies on newer technologies and their potential impact, including electrical- signature analysis, ultrasonics, motion amplification, and the Internet of Things (IoT).TRR

Click The Following Links For Previous Articles In This Series on The Reliability Of Large Electric Motors”

March 28, 2020: “What The Studies Really Said”

April 12, 2020: “Comparing What The Studies Said”

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: motors, drives, electrical systems, power generation, reliability, availability, maintenance, RAM, EPRI, IEEE