Power quality involves a variety of impacts on the Voltage supply, the Current, and the grounding system While many standards and documents emphasize one part or another, the reality is all of these factors impact each other. Unfortunately, except for advanced techniques such as power studies, few resources address the complexity that the combined conditions exert.

In our previous articles on the mysterious power factor and understanding harmonics, we noted that the poorer these conditions, the greater the system is ‘tuned’ or loaded.

During electric motor starting, especially across-the-line starting, the electric machine will generally pull 4-8 times the full load current. When a system is heavily loaded, the result will saturate components including cables and transformers, resulting in a Voltage drop. The more significant the drop, the longer a machine will take to get up to speed and the greater the chance that electronic systems will drop out.

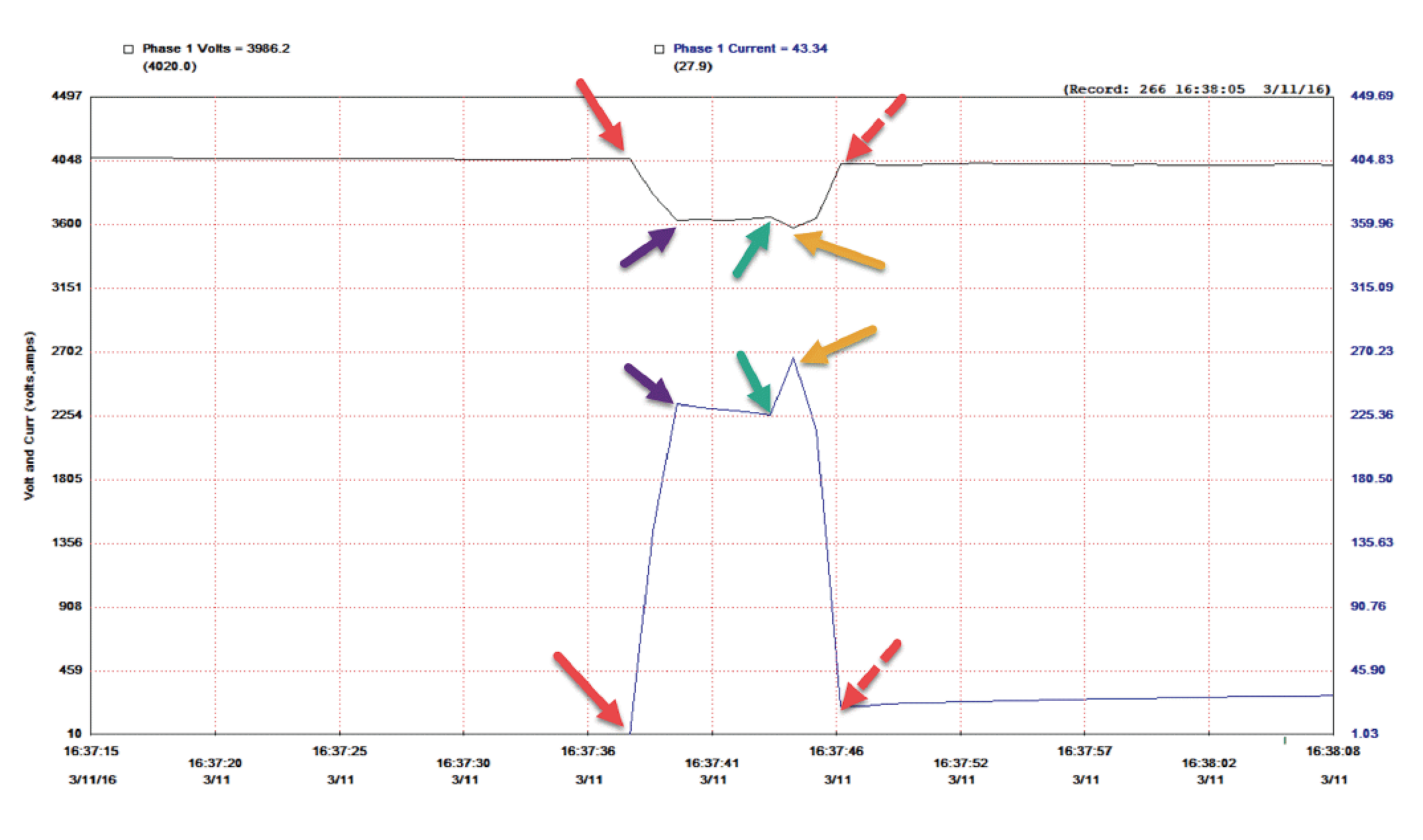

Fig 1. Inrush Current and Voltage drop during motor starting

One way that electric motors reduce this impact is through soft-start systems, of which there are many types.

For example, the data points in Fig. 1 reflect a an actual 4000-horsepower, 4160 Vac electric motor started with a line reactor. A line reactor drops the Voltage supply to that of the motor to reduce the locked-rotor torque and potential damage to the motor’s base and driven equipment. This application had a very low true power factor, and a medium voltage drive tripped during the motor startup.

- Red Arrow: 16:37:36 (time), 4055.6 Volts and 0 Amps before the motor is started;

- Purple Arrow: 16:37:39 (time), 3814.4 Volts and 144.4 Amps initial starting current with line reactor;

- Green Arrow: 16:37:43 (time), 3640 Volts and 228.1 Amps as the controls and contactors transition from reactor start to across the line start;

- Gold Arrow: 16:37:45 (time), 3574 Volts and 266.2 Amps peak after transition; and,

- Red-Dash Arrow: 16:37:48 (time), 4022.4 Volts and 21.1 Amps operating at no-load.

As a result, total start time was 12 seconds with a maximum voltage drop of ((4022.4V – 3574V)/4022.4V) * 100% = 11.15%. The associated variable frequency drive (VFD) tripped as it had a maximum 10% voltage-drop capability from 4160 Volts (3744 Volts) and a base setting of 10-seconds ride-through, or the length of time that the drive would continue to run with low to no voltage supply.

The initial solution was to increase the ride-through time to 14 seconds, which would impact the drive life, depending on the number of starts with the 4000-horsepower motor.

During a review of the situation, investigators noted a very high harmonic content in the system resulting in a True Power Factor of about 0.44. The recommendation was to increase the True Power Factor through either harmonic correction, such as an active filter, or properly sized filters on power electronics.

The Apparent Power Factor in this example is about 0.92, pointing to a significant amount of system capacity being lost due to power-electronic-based harmonics. The recommended correction would impact the overall system and, very likely, affect other system issues that might not be as obvious as the VFD trip.TRR

CLICK HERE to read “The Mysterious Power Factor” (Oct. 22, 2019)

CLICK HERE to read “Understanding Harmonics” (Nov. 14, 2019)

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email howard@motordoc.com or info@motordoc.com and/or visit motordoc.com.