Electric Motors: A Perfect Precision Maintenance Canvas

Application, setup, and regular maintenance are cornerstone elements of precision maintenance. Together, and done right, they can help your motors lead long, efficient, productive lives.

Is Your Asset Management System Still Legacy Based?

Legacy-based maintenance systems and approaches may have worked quite well in the past. But that doesn’t mean they’re really up to the changing demands of today and tomorrow.

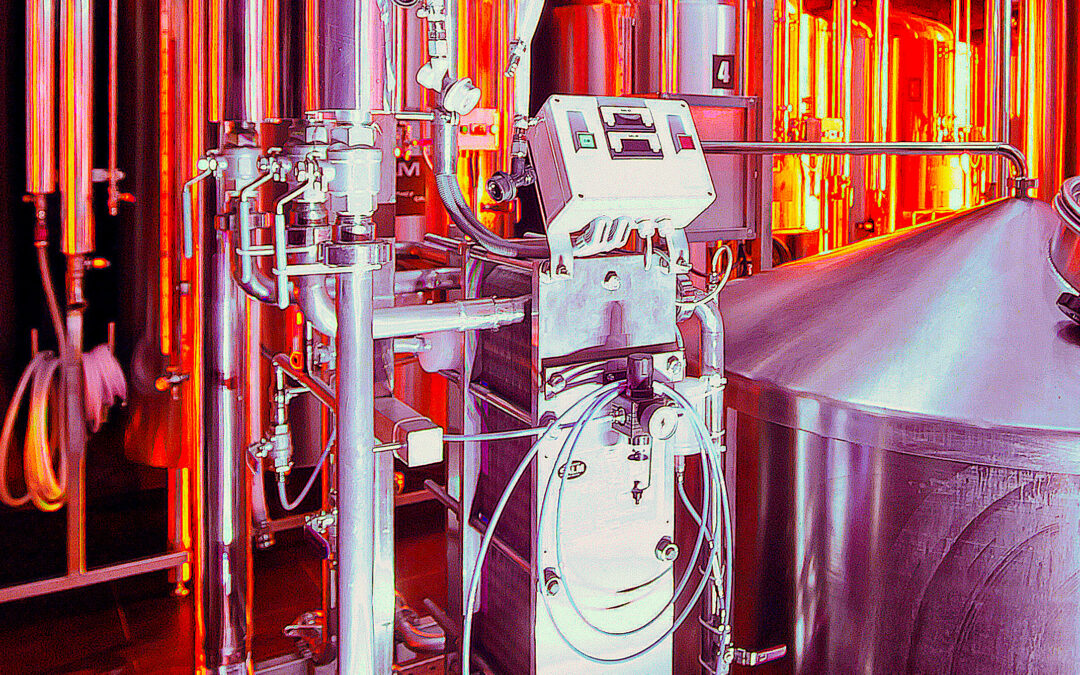

Digital Inventory App for Liquid-Led Production

ABB Ability Liquid Routing Library ups efficiency, cuts costs with routing and CIP capabilities.

Have You Ever Heard of Flixborough?

An account of a plant disaster that occurred almost 50 years ago offers a sobering lesson for today’s reliability professionals: A bad piping decision led to deaths and destruction.

The Challenges of Work Instructions

Think of detailed maintenance-work instructions as “procedures” and checklists as “reminders” of what’s to be accomplished by procedures. That’s not always understood.

Environmental Perspectives on Asset Management (Up and Down The Supply Chain)

No plant or facility is an “island” when it comes to environmental and societal concerns. Growing ranks of worried consumers will make sure manufacturers grasp that message.

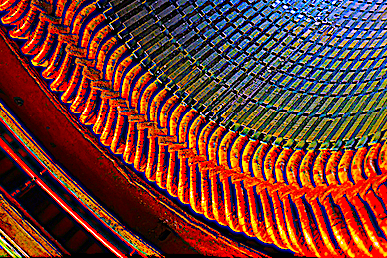

Electrical Signature Analysis (ESA) & Stator Winding Issues (Part II)

In a literature search, the author found few technical papers on vibration-related stator-slot defects in electric machines. So, he examined the problem, then shared his theory here.

Field and Panel Mount Process Displays

AutomationDirect’s ProSense LPM1 series digitally displays analog 4-20mA signals.

The Case Against Becoming Parts Changers

A failed bearing or other mechanical component might mean the part really is bad. But if it’s replaced without determining the actual root cause, prepare for possible repeat failures.

Precision-Work Instructions Are Crucial in STO Events

These types of instructions reflect a simple, value-adding concept, yet seem an endangered species in STO plans. Too bad. Dealing with poor work-quality after an STO is no picnic.