Look To Tribology To Reduce Climate Change Impact

As Dr. H. Peter Jost estimated, we could reduce energy consumption by 7.5% through better management of friction in tribological systems That’s a winning proposition for plant equipment and the planet.

Tutors Can Keep You From Making Mistakes

‘Tutors’ come in many forms, including books and knowledgeable manufacturers. Don’t hesitate. Take advantage of these resources to boost your RAM I.Q. and support your professional development goals.

Understand The Bearing Lifecycle

A clear understanding of the five life stages of bearings and associated built-in and application failure modes leads to the development of more effective premature-failure strategies at a site.

The Economics of Manufacturing Machinery Maintenance, With Doug Thomas of NIST

Howard Penrose and Alidade MER’s Tom Moriarity talk with Doug Thomas of NIST’s Manufacturing Machinery Maintenance Program about the impact of some recent studies on RAM pros and corporate goals.

Operator-Performed Maintenance (Part I): Benefits And Barriers

Think in terms of operator “care” rather than “maintenance.” Then keep in mind that when properly deployed, operators can provide the most efficient/effective type of preventive maintenance in a plant.

The RAM Pro’s Primer On Scope 1, 2, And 3 Greenhouse Gas Emissions

Those working in the RAM arena typically have responsibility for performance of equipment that produces GHG emissions. This means they’re also in a position to help control those types of emissions.

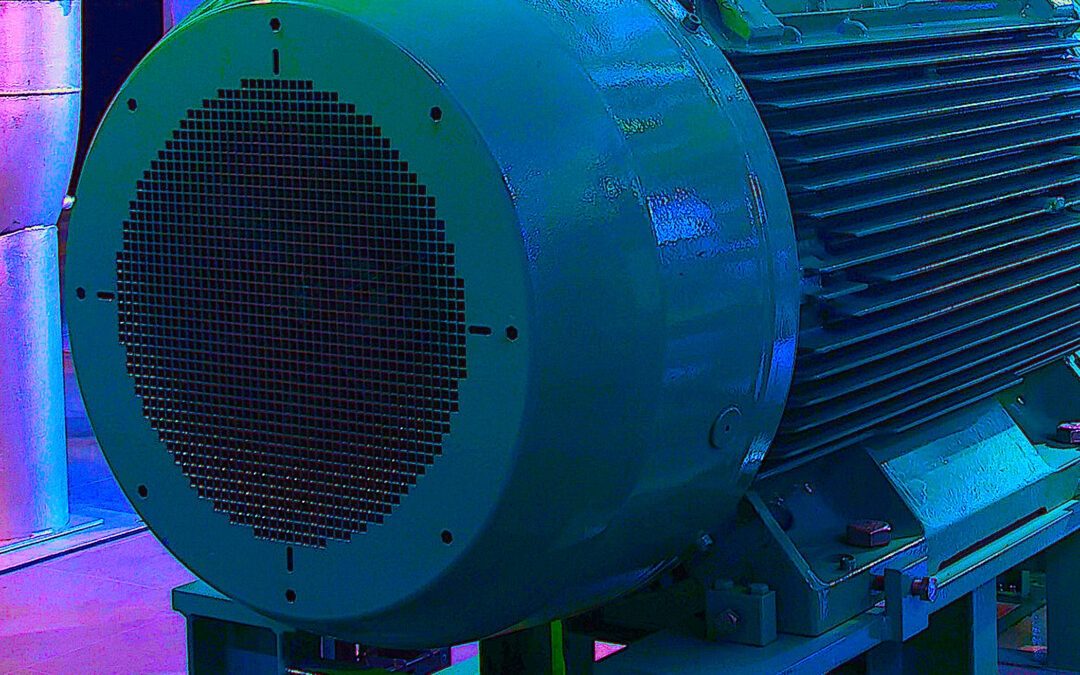

Electrical Signature Analysis Air-Gap Eccentricities (Part II): Alignment Case Study

The case study highlighted here involves the motor in a pumping application that runs on a VFD. An improper alignment practice had caused problematic static eccentricity. The fix was fairly simple.

Wireless-Sensor Technologies: Pros And Cons

Advancements in technology have dramatically changed how equipment and process data is collected across industry. That said, it’s important to note that today’s offerings aren’t one-size-fits-all solutions.

Visual, Audible Signal Devices/Beacons

Wermal EvoSignal visual-audible solutions from AutomationDirect meet a variety of application needs.

Precision Maintenance Requires Precise Language

The English language allows use of many imprecise words that cast doubt on the intended meaning. The type of misinterpretation and confusion that can result could lead to work-order problems.