The potential to reduce the environmental impacts of industrial operations with better management of parasitic frictional losses is well-documented. The science and technology associated with surfaces in relative motion, including friction, wear, and lubrication is the definition of tribology. Dr. H. Peter Jost, who coined the term “tribology,” estimated, in his seminal 1966 document known as “The Jost Report,” that we could reduce energy consumption by 7.5%, if we better managed friction in tribological systems. Let’s explore how to do just that.

BASIC STRATEGIES

Numerous case studies report that industrial organizations have successfully and dramatically reduced energy consumption through better management of friction. Precision shaft and pulley alignment, precision mechanical and electrical balance, and improving structural integrity with correct mechanical fastening techniques all reduce vibration and associated mechanical friction. Proper selection, application and management of lubricants and hydraulic fluids likewise reduces friction. Selecting high efficiency motors, opting for variable frequency drives (VFDs), and effectively managing electrical systems and circuits reduces energy consumption.

In turn, proper management of tribological systems reduces friction, energy waste, and the impact of your plant on climate change. But that’s not all: It reduces equipment wear and degradation (which is also great for an organization’s company’s bottom line).

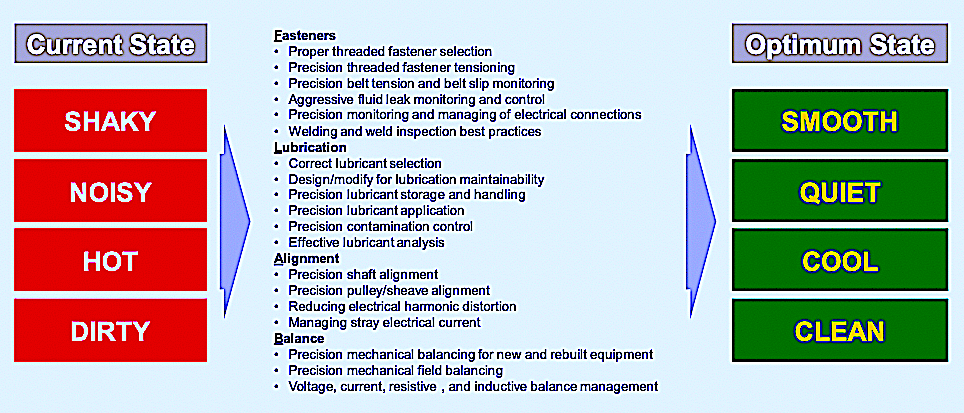

If your machines are currently shaky, noisy, hot, and dirty, you’re wasting energy. Reducing parasitic friction with tribology management results in machines that run smooth, quiet, cool and clean (Fig. 1). Achieving this goal reduces energy consumption and the plant’s carbon footprint. It also increases machine reliability and productive output, while reducing safety risks and operating costs.

Fig. 1. Friction management for mechanical systems, in a nutshell,

focus on the FLAB (fasteners, lubrication, alignment, and balance).

RELEVANT CALCULATIONS

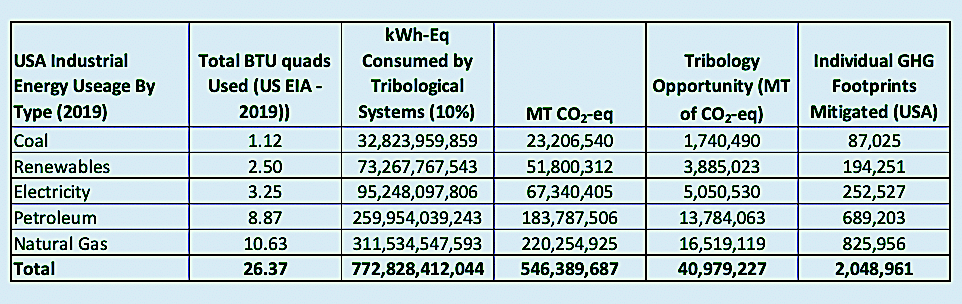

According to the U.S. Energy Information Administration (EIA), heavy industry accounts for about 32% of all end-use energy consumed in the United States, which equals just over 26 quadrillion (quad) British Thermal Units (BTUs) for all energy types. Different energy sources emit varying degrees of carbon dioxide equivalent (CO2-eq) units per BTU. However, in the interest of simplicity, I’ve converted quad BTUs to equivalent kilowatt hours (kWh) for this article. One kWh of energy consumed emits 0.707 kg of CO2-eq according to the U.S. Environmental Protection agency (EPA). The conversion of 26 quad BTUs to kWh equals about 7.6 trillion kWh, which results in emissions of about 5.4 billion metric tons (MT) of CO2-eq. While the percentage of this energy that is employed to power what might be classified as industrial tribological machines varies widely by industry, according to the EIA, it averages about 10%, or about 760 billion kWh per year in the USA. This percentage equates to nearly 540 million MT of CO2-eq of GHG emissions that can be attributed to industrial tribological machines.

TRIBOLOGY’S HUGE POTENTIAL

To recap, the focus of tribology is to minimize parasitic energy losses caused by sources of friction that we can reasonably manage. Assuming that Professor Jost’s estimate about our ability to reduce energy consumption in tribological systems by 7.5% is correct, we have the opportunity to reduce energy consumption by nearly 58 billion kWh per year in the U.S. alone, which results in a reduction of 41 million MT of CO2-eq per year by improving industrial tribology practices. Assuming a social cost of carbon (SCC) estimate of $50 per metric ton, the impact of the reduced GHG emissions would exceed $2 billion per year.

Let’s put this opportunity into perspective at the human level. The average American has a greenhouse gas (GHG) footprint of about 15 to 25 MT of CO2-eq per person, per year. Improving industrial tribology and lubrication practices in the U.S. could offset the annual GHG footprints of more than two million people (Fig. 2). While improving industrial tribology practices alone can’t entirely solve our climate-change challenge, doing so would have a remarkable impact on the problem. Achieving only one-half, or even just one-third of the suggested improvements would still constitute a significant environmental victory.

Fig. 2. Opportunity to reduce GHG footprints with better management of industrial tribology.

Fig. 2. Opportunity to reduce GHG footprints with better management of industrial tribology.

REAL-WORLD CASE IN POINT

The mining industry offers an example illustrating the opportunity to reduce our carbon footprint by improving industrial energy efficiency. In a 2007 report by the US Department of Energy (DOE), the mining industry used 1.246 quad BTUs of energy for all usage activities (this estimate differs from the EIA, which reports that the mining industry utilized 11% or about 2.09 quad BTUs of all industrial energy consumed in 2019). The report suggested that employing energy management best practices in the mining industry would result in a 20.7% reduction in energy consumed. However, they suggest what they call a “practical minimum,” for mining energy consumption that would reduce energy consumption by 53.5%. The DOE also reported a “theoretical minimum” energy consumption, but suggested that its not a reasonable basis for comparison, a point on which I agree.

Based upon 2019 EIA data on energy consumption in the mining sector alone would, by employing 2007 best practices, reduce GHG emissions from the U.S. mining industry by more than 12 billion MT of CO2-eq per year (2019 numbers). Employing practices that achieve the 2007 definition of the practical minimum would reduce GHG emission by more than 32 billion MT of CO2-eq per year (2019 numbers). Those impacts would offset the climate change impact of 622,065 and 1,607,752 people respectively under the two scenarios. That’s the impact for the mining sector alone: The opportunity for industry to reduce its carbon footprint with effective energy management practices is enormous.

BONUS: INCREASED SAFETY & PROFITS

The focus of this article is reducing energy waste, and associated GHG emissions, by targeting and managing parasitic energy losses attributable to friction. However, there are some other motivators. Assuming a cost of $0.05/kWh, industrial facilities in the U.S. would reduce their collective annual energy bill by about $3 billion per year. Additionally, the same root causes of friction that waste energy also cause wear, degradation, and failure of electro-mechanical systems. It’s possible to double or even triple the life of many machines by proactively managing friction, which further boosts production throughput and reduces costs.

Moreover, every required maintenance event in a plant or facility carries some safety risk. Reducing friction reduces wear, which reduces the number of failures to which we must respond. The law of large numbers dictates that safety incidences will reduce accordingly.

In closing, proactively managing friction in your plant is good for the environment, good for your bottom line, and good for the safety of a plant’s team members. Let’s get to work on it.TRR

REFERENCES

Jost, H Peter, & Schofield, J. (1981). “Energy Saving through Tribology: A Techno-Economic Study.” Proceedings /Institution of Mechanical Engineers, 195(1), 151-173.

U.S. Energy Information Agency (EIA). Use of energy explained: Energy use explained – 2019. https://www.eia.gov/energyexplained/use-of-energy/industry.php. Accessed 21 November, 2020.

U.S. Environmental Protection Agency (EPA). Greenhouse gas equivalencies calculator: Calculations and references. https://www.epa.gov/energy/greenhouse-gases-equivalencies-calculator-calculations-and-references. Accessed 21 November, 2020.

U.S. Department of Energy (DOE) Industrial Technologies Program (2007). Mining Industry Energy Bandwidth Study. https://www.energy.gov/sites/prod/files/2013/11/f4/mining_bandwidth.pdf. Accessed 21 November, 2020.

ABOUT THE AUTHOR

Drew Troyer has 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 250 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees, and is Master’s degree candidate in Environmental Sustainability at Harvard University. Contact him directly at 512-800-6031 or dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, H. Peter Jost, The Jost Report, tribology, tribological systems, lubrication, precision maintenance, environmental sustainability, sustainable manufacturing, energy efficiency, safety, climate change, sustainable investment, sustainability performance