‘We Can Only Achieve Digital Transformation Together’

An interview with Andreas Weber, Ph.D., of Enovik, provides insight on the 4th Open Production & Maintenance Community e.V (4th OPMC) and its aim to help safeguard Germany’s economic future in the context of digitization.

When Rules Of Thumb Aren’t Your Best Friends

These “rules,” AKA “heuristics,” don’t require us to exert much mental energy. But they’re risky. Coupled with individual and organizational biases, they can fuel suboptimal decisions and undermine a plant’s reliability and safety goals.

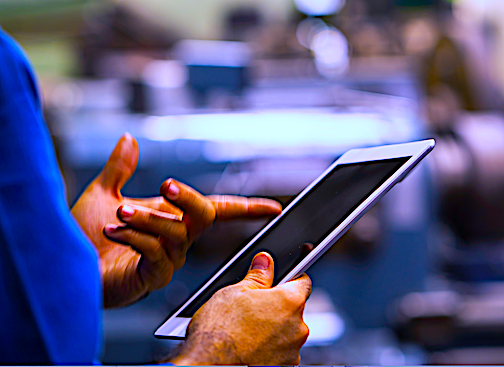

Capitalize On Your Technology Toolbox

Whether a plant is running at full or over-design capacity or in partial, slow-down, or shut-down mode, its maintenance teams and operations will benefit greatly from access to and deployment of a robust technology toolbox.

Multi-Technology Testing Case Study 2: Vibration Motion Amplification And Electrical Signature Analysis

When using individual technologies, most technicians are looking for problems that relate specifically to their chosen tool. Thus, they can miss minor issues that technology doesn’t detect. Multiple methods in tandem reveal much more.

Detailed Maintenance Work Instructions (Part II): A Development Model

These types of work instructions are meant to drive out the natural “human variation” in the way people do things. Think of the model outlined here as a starting point for a variety of continuous improvement at a site.

The Four-Step Approach To ‘Delegating’

Dedicated employees who are willing and able to respond to balanced and thoughtful direction are some of the most valuable resources in today’s plants. Wise use of these resources means that all parties win.

Detailed Maintenance Work Instructions (Part I): Why Use ‘Em?

The author refers to this type of instruction as “the world’s best maintenance tool.” But if plant personnel don’t understand the power of such instructions, or can’t or won’t follow them, operations lose out.

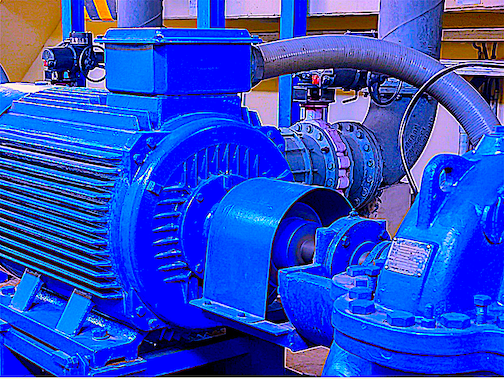

Multi-Technology Testing Case Study 1: Electrical Signature Analysis And Motion Amplification

Base looseness appeared to be the culprit in a critical motor’s vibration woes. Actual confirmation of this observation was another matter. The author leveraged two proven methods to provide it.

Delegating Responsibility Brings Benefits

Business as usual may be over for a while. Nevertheless, in many down-sized, reshuffled plants dealing with pandemic issues, some reliability pros could still be trying to single-handedly do more than is reasonable or prudent.

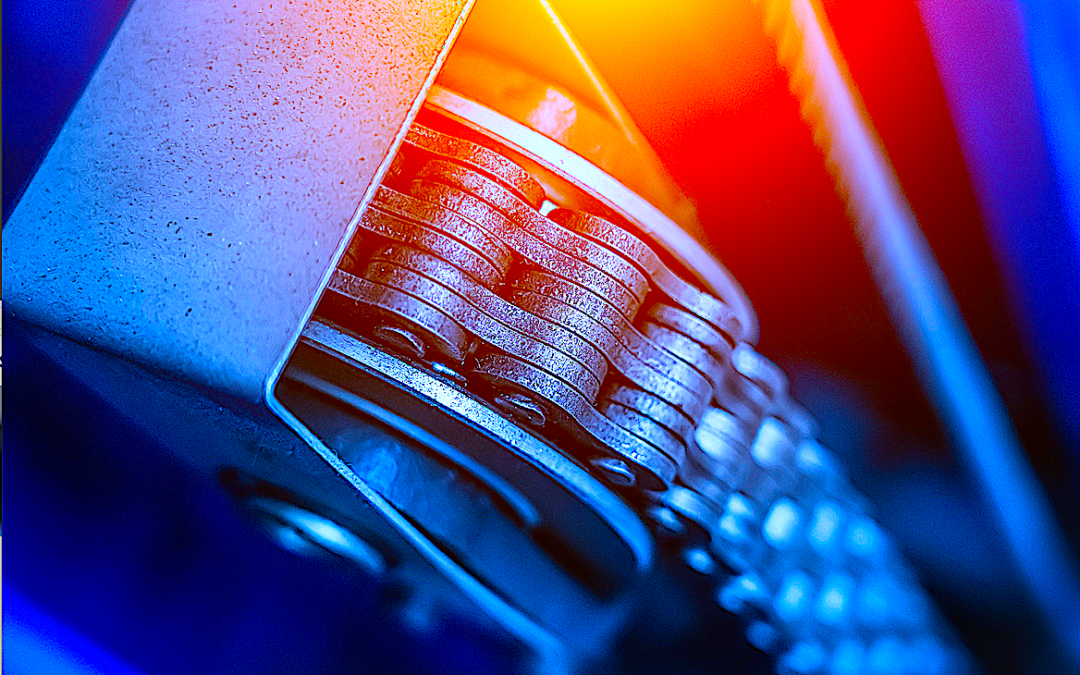

Keep Your ‘Creep To Failure’ Systems In Check

“Weak links” impact reliability. Following up on his article about hydraulic-system maintenance, the author discusses proper care of the long suffering, often overlooked chain, sprocket, and belt workhorses in plants.