Leading Indicators For Asset Management: OME (Overall Materials Effectiveness)

Maintenance work can’t be effectively and efficiently executed without parts needed to complete the job. Chasing down those items is a wrench//spanner-time killer. Look to OME to change the dynamic.

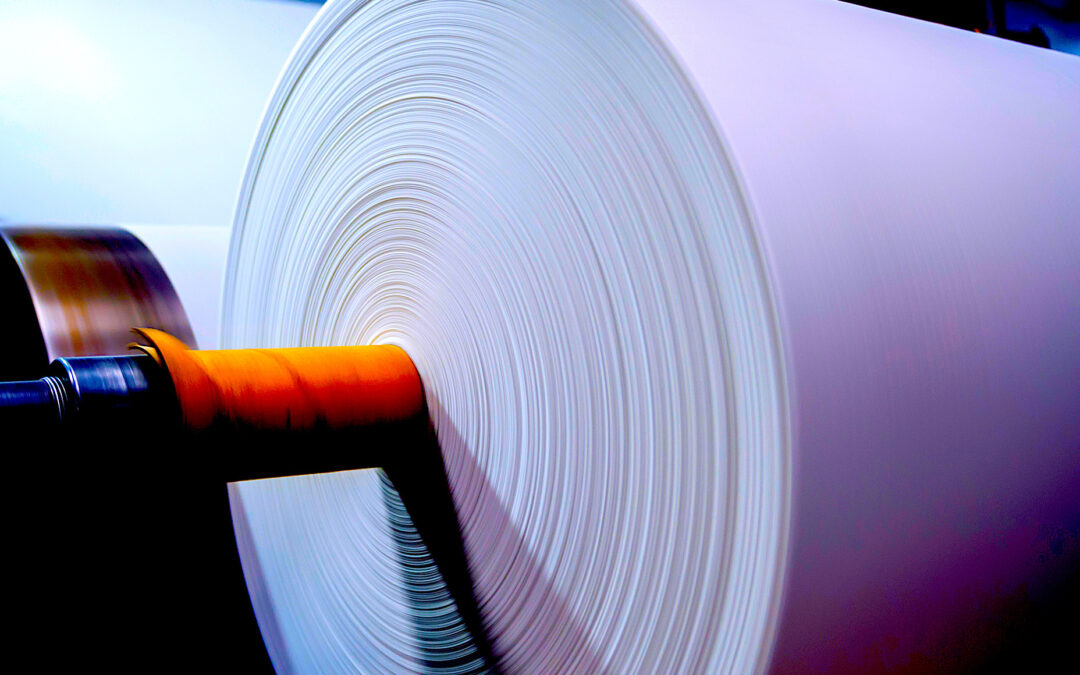

‘Pit-Crew’ Perspective: A Paper-Mill Turnaround

Despite their focus on major pieces of equipment, pit stops and STOs are more about teamwork and leadership than machines. Efficiency and effectiveness are keys to winning these “races.”

Test Your Knowledge On Best Practices For Centrifugal Pumps

Could your site be among those that are lacking in their application of pump fundamentals? The author offers this quiz as a way to begin checking out a plant’s mastery of the basics.

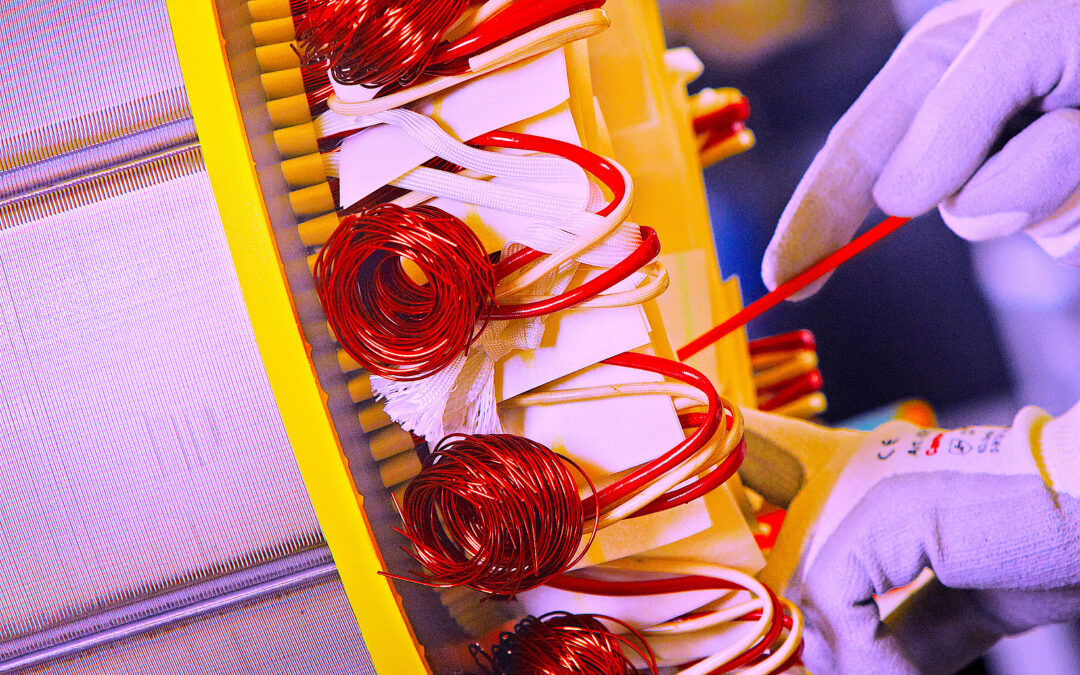

Beware Stator Inter-Turn Stress In VFD Applications

If a VFD is set incorrectly, or not tuned if straight volts/hertz settings aren’t used, stresses occur between turns in windings. Resulting current discharges can adversely affect the motor.

Yes, We Can Make Manufacturing Better

This column highlights an important report out of Northeast Ohio that offers a blueprint for upping the region’s manufacturing game. It can also work in other states and regions.

Leading Indicators For Asset Management: OSE (Overall Scheduling Effectiveness)

Minimizing Mean Time To Repair (MTTR) is essential for increasing production availability in plants. Doing so requires effective maintenance scheduling. That’s where OSE comes in.

‘Smart’ Everything: The Impact On The Future Of Reliability And Maintenance Operations

In this concluding article of his short series on “smart” technologies and their impact on our lives and livelihoods, the author ties everything together from a RAM standpoint.

To The New Maintenance Order: Making Your Mark

Industry’s need for quality maintenance-skilled trades has never been more acute. Opportunities for the ‘new order’ of maintenance pros that will fill the void are virtually endless.

Supplementing The Operator’s Role Statement

Operators play a critical role in achieving equipment reliability at a site. The author discusses concepts that pacesetter facilities would want to emphasize in operator training.

Achieving STO Targets With Team Alignment

Getting the scope of an STO right impacts the cost and duration of the event. Excellent team alignment is key to successful scope control and supports the organization in meeting its goals.