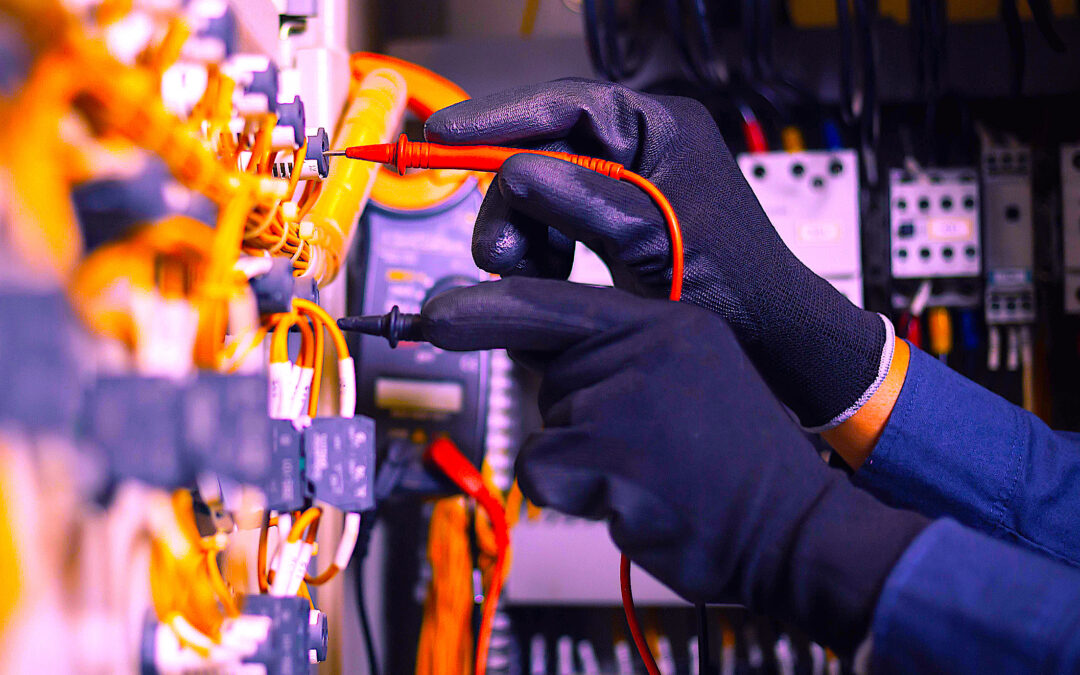

Part III, More Thoughts On Electrical Reliability (Specifically, Surveys)

This article discusses the scope of a basic electrical-infrastructure review and how it can be performed. It’s based it on the author’s approach to industrial-energy-assessment walk-throughs. He’s done plenty.

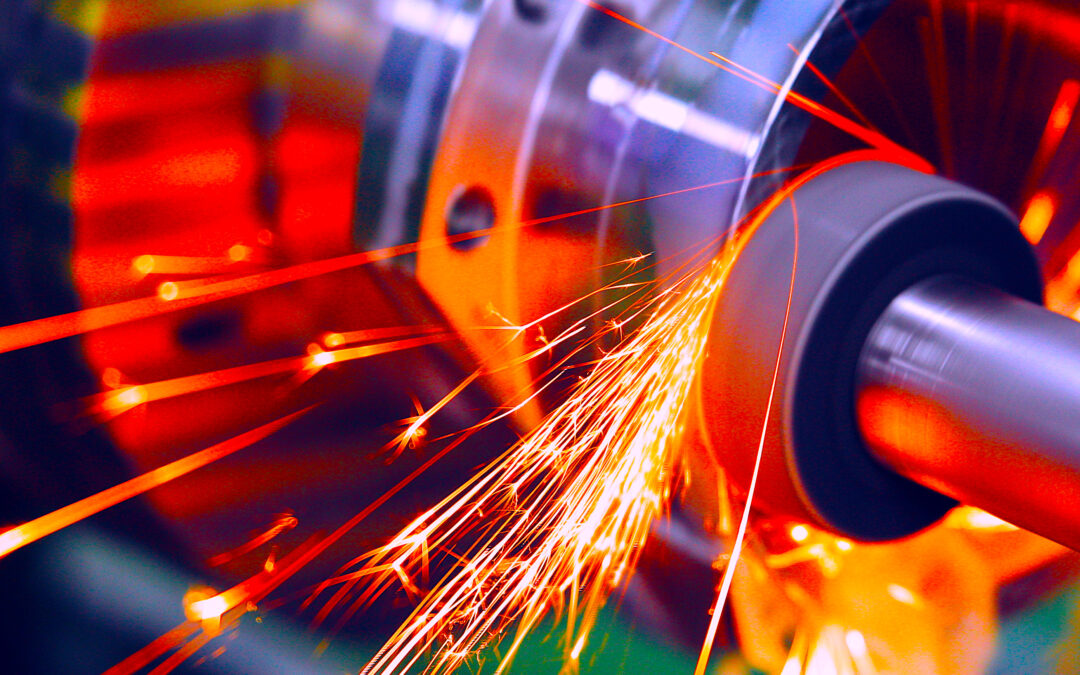

Customer Success Story: LLDPE Plant Operator Increases Rotary Feed Drum Performance And Reduces Downtime

Demanding environments are tough on component wear life. This story of a linear low-density polyethylene manufacturing operation in Texas is a case in point. The solution paid off quickly.

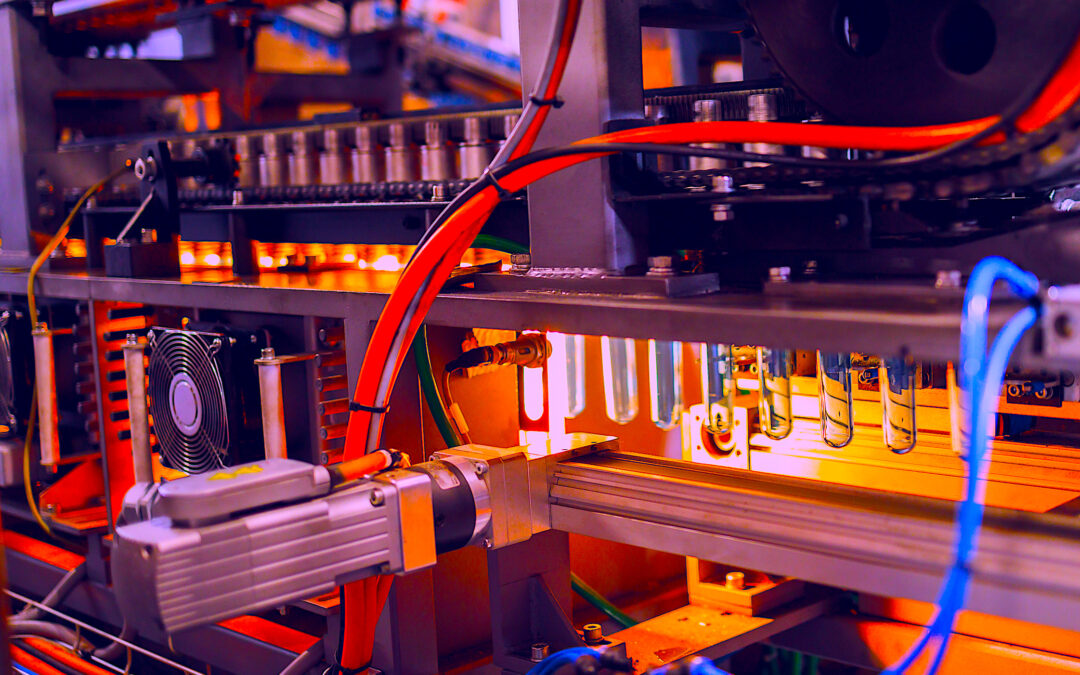

Lean Equipment Management: Putting Its 7 Principles To Work (Part 4)

Keep in mind that the approach discussed in this ongoing series of columns is a “Focused Improvement Strategy,” not a Lean program or lean toolbox to implement in the hopes of improving performance.

Bearing And Lubrication Considerations In Pump Failure Distribution

The problem isn’t new. Fault-inducing details are often overlooked in plants and facilities. When all is said and done, recognizing and understanding them is one of the true keys to asset performance.

Part II, More Thoughts On Electrical Reliability

At the Point of Common Coupling, the utility has responsibilities for power quality, as does the customer for how its own equipment and loads impact the power at that point. The author explains.

Lean Equipment Management: Putting Its 7 Principles To Work (Part 3)

Leveraged correctly, the first principle of lean equipment management has an awesome power. Given all that power can do, the goal of ZERO losses is certainly within reach in today’s plants and facilities.

Part I, More Thoughts On Electrical Reliability

As our plants and grid age and reliability decreases, scoring the criticality of electrical systems still remains a second thought. If criticality is even considered. For this author, though, it’s top of mind.

Preparing Stored Equipment For Re-commissioning (Re-starting After Long Periods Of Preservation)

Before proceeding with the recommendations in this oil-mist-related article, it’s crucial for Reliability Pros to consult with the stored equipment’s OEMs, appropriate lube suppliers, and crews tasked with implementation.

Lean Equipment Management: How To Put Its 7 Principles To Work (Part 2)

In a LEAN mindset, RAM Pros must consider anything that affects production process flow, especially relating to known production bottlenecks. This column puts some equipment losses in context.

You Really Can: Harvest Electrical Savings From Your Compressed Air Systems

In plants using large amounts of compressed air, the greatest energy savings come from dealing with leaks and general system efficiency. Good leak programs can drop related costs by 30 to 40%.