in this week’s article, we wrap up our short series of discussions around the first of the three parts (“Volumes”) of the 2021 “U.S. Industrial and Commercial Motor System Market Assessment Report.” In doing so, we need to consider the impact that a variety of changes since publication of the 1996 report have had on the economy. It’s noteworthy.

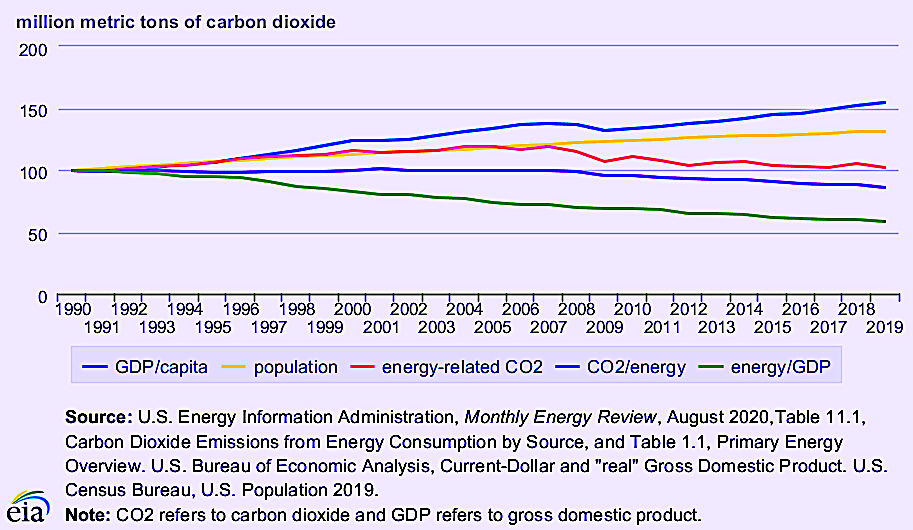

From an energy and environmental perspective, energy per Gross Domestic Product (GDP) in million metric tons of CO2 dropped from 94 to 86 between 1996 to 2019 (see Fig. 1 from the U.S. Energy Information Administration [EIA]). What effect has this had on industrial and commercial bottom lines?

Fig. 1. Index of GDP/capita, population, CO2/energy, and energy/GDP that influence energy-related emissions.

AMONG THE FINDINGS

As for energy-efficiency in particular, 49% of industrial facilities and 59% of commercial facilities consider energy efficiency in motor-system components, from controls to couplings and driven equipment. Fifty-eight percent of industrial and 67% of commercial sites consider energy efficiency in the design of new motor systems. And, while larger industrial facilities consider electric-motor efficiency more than smaller sites, smaller commercial sites consider efficiency more than larger commercial sites.

This study also found that, across the United States, industrial facilities experienced more than 6 million hours of unplanned downtime due to electric-motor failures. U.S. commercial facilities experienced more than 8 million hours of unplanned downtime for the same reason. The combination of understanding your motor systems through inventory and taking steps to reduce unplanned outages provide a significant opportunity for improving the bottom line. As noted in the National Institute of Standards and Technology (NIST) “Manufacturing Machinery Maintenance Study” at this link, the implementation of an advanced maintenance program will improve uptime, reduce energy costs, and improve productivity while improving safety.

Keep in mind that each defect associated with the motor system has an energy aspect associated with it. For example, long before its actual failure, as a defective bearing degrades, it increases the watts lost across the motor system. This rise in energy consumption, in turn, increases the cost of operating the motor. Thus, when applied across an entire industrial or commercial site, the opportunities related to implementation of an advanced maintenance program will have an impact far beyond an energy improvement of 14% (U.S. Department of Energy Industrial Assessment Guide, Rutgers University).

We’ll provide an analysis of Volume 2 of this report when it becomes available later in 2021.TRR

Click Here To Read Part I (Feb. 14, 2021)

Click Here To Read Part II (Feb. 27, 2021)

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at [email protected], or [email protected], and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, motors, drives, USDOE, United States Department of Energy, USDOE Industrial Technologies office, energy efficiency, National Institute of Standards and Technology, NIST, Energy Information Administration, EIA