by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Aug 29, 2020 | Planning & Scheduling, RAM Tools & Methods

Developing objective and effective work instruction is a science. The quality of work performed by a maintainer when following a planner’s instruction will vary greatly depending on the objective requirement set within each line of instruction. If direction is vague,...

by Tim Dunton, CMRP, CMRT | Aug 28, 2020 | Asset Management, RAM Tools & Methods

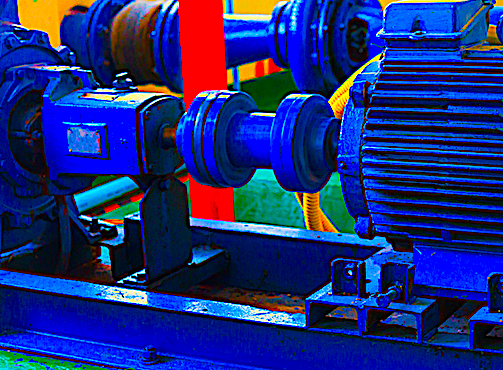

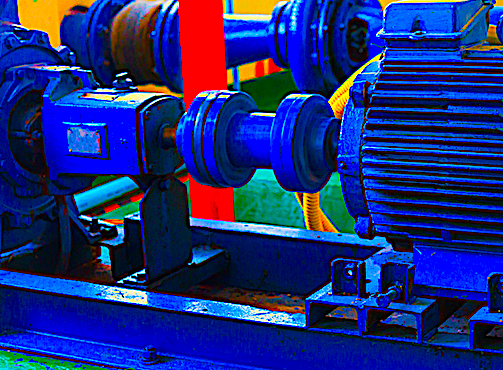

Cursory soft-foot checks are often performed as means of “checking the box” at the start of an alignment process. If, however, we are to eradicate soft foot from the industrial landscape, these checks need to become an integral part of the alignment process and be...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Aug 21, 2020 | Planning & Scheduling, RAM Tools & Methods

A maintenance work order (MWO) is basically made up of three distinct sections. The first section, which was covered in The RAM Review article “Make Work Orders Work (Aug. 17, 2020), contains the general information required to raise a work order and make it an...

by Tim Dunton, CMRP, CMRT | Aug 20, 2020 | Asset Management, RAM Tools & Methods

In last week’s article for The RAM Review (August 14, 2020), we discussed some of the tools needed to implement precision maintenance. This week we focus on what is, perhaps, one of the most important tools. Documenting results and what was done on a job is crucial in...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Aug 15, 2020 | Planning & Scheduling, RAM Tools & Methods

The maintenance work order (MWO) is, unequivocally, the most important tool in the maintenance department. Unfortunately, many maintenance shops look upon work orders as nuisance items that take time to produce and complete. As a result, work orders are often reduced...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Aug 15, 2020 | RAM Tools & Methods, Workforce Issues

How time flies. It was another place and another time. I first wrote about the following stories over 16 years ago. Given the timeless nature of their reliability angles, I’m hoping my re-telling of them here will be of interest to newer members of the...

by Tim Dunton, CMRP, CMRT | Aug 14, 2020 | Asset Management, RAM Tools & Methods

In last week’s article (Aug. 7, 2020), we discussed elements involved in building a plan for implementation of precision maintenance at a site, including the selection of candidate equipment/machines for improvement and metrics. This week, the focus is on tools. Note,...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Aug 8, 2020 | RAM Tools & Methods

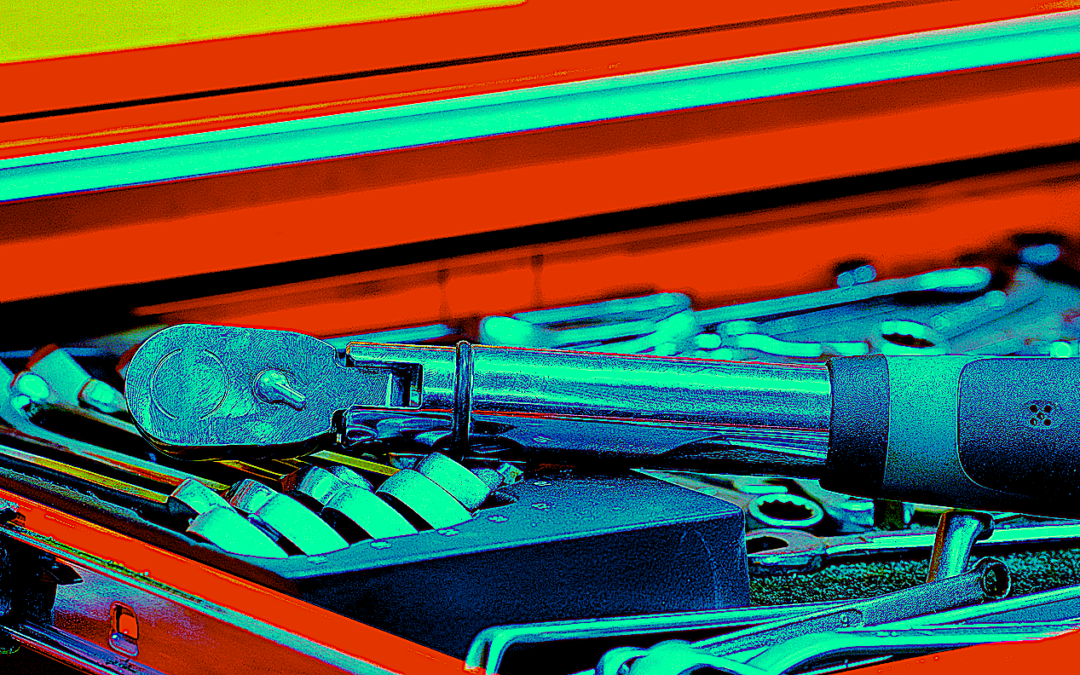

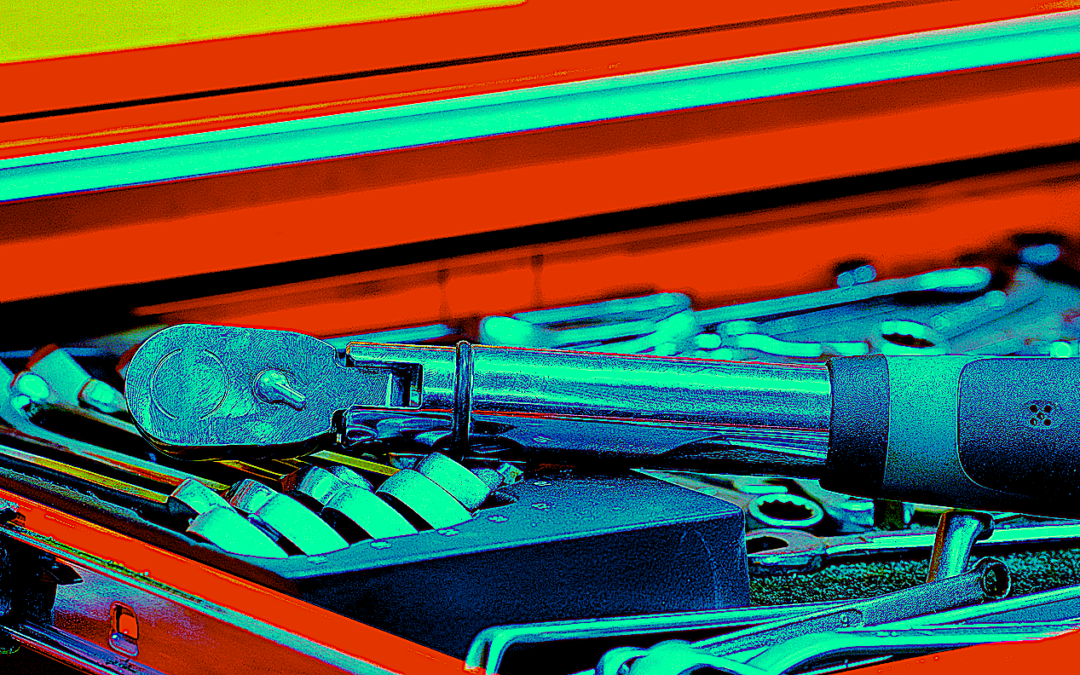

Have you ever spent time on the job looking for a specific tool you thought was in your toolbox? Have you ever cut yourself rummaging through a sea of tools trying to find a specific tool? Do you carry multiples of the same tool of differing quality that could cause...

by Tim Dunton, CMRP, CMRT | Aug 7, 2020 | Asset Management, RAM Tools & Methods

In the last week’s article (Aug. 3, 2020), we discussed how to develop the strategy for implementing precision maintenance in a plant. This included setting strategic, tactical, and application goals and metrics. These goals set out what we are going to try to...

by Tim Dunton, CMRP, CMRT | Aug 1, 2020 | Asset Management, RAM Tools & Methods

In last week’s article, we took a quick look a what precision maintenance is and the four main steps for implementing it. Those steps include: 1) Creating the Strategy, 2) Building a Plan, 3) Applying the Work, and 4) Capturing Results. Here, we focus on the first of...