In last week’s article for The RAM Review (August 14, 2020), we discussed some of the tools needed to implement precision maintenance. This week we focus on what is, perhaps, one of the most important tools. Documenting results and what was done on a job is crucial in sustaining a precision-maintenance effort.

The essayist George Santayana is often credited with the phrase, “Those who cannot remember the past are condemned to repeat it.” Documentation is the way we remember the past. With a large percentage of our skilled workforce retiring in the next decade or so, if plants don’t find a way to capture their vast reserves of institutional knowledge, it will be lost. Documentation is a big part of the solution.

There are several types of documentation required for precision maintenance. At the application level, we have technician field notes that cover the work that was done and the immediate improvements made. Tactical documentation tracks and communicates our progress at the tactical level. Finally we have strategic documentation that captures strategic performance and communicates progress toward strategic goals.

FIELD NOTES

By definition, field notes are what technicians use in the field to document individual jobs. The forms should include pre- and post-performance data to show improvement. Such data includes vibration, temperature, speed and energy consumption. By documenting performance this way, technicians can clearly see the effect that they and their work have had on machines, which is a big part of motivation. While some facilities let existing condition-monitoring teams collect performance data, that doesn’t produce the degree of motivation that comes from from mechanics taking the readings themselves.

Field notes should also detail the work that was done. This allows us to begin creating the aforementioned history. That doesn’t always get done. Completion notes and history in sites’ CMMS programs typically include a lot of “Job complete” or “Work order Complete” notices that give the date the job was complete and, maybe, some man-hours and parts used. But there’s often almost no real detail on what was done, what was found, and, possibly, how to make things better. Why is this?

MAKING PAPERWORK HARDER

Most of us, including many technicians, abhor paperwork and look upon it as time-consuming busy work. This is because paperwork presents us with little or no perceived value.

When designing forms and checklists we often deliberately focus on making the paperwork shorter and easier. The result is that we have a nice, concise checklist/procedure that is very easy to pencil whip, effectively removes thought from the process, and often completely de-motivates the technician, who may have been performing the task for 30 years and is quite insulted by now having to use a checklist. Although there are are basic psychological reasons for this behavior around the removal of autonomy, discussing them is beyond the scope of this article. There is, however, one simple change to the way a form is created that will improve motivation: Phrase the instruction in the form of a question.

Instead of a line item that says “Check the bearing fits” and a check box with a notes field try this: Ask, “What was the bearing fit?” Then provide a field to capture the fit data. This approach is much harder to pencil whip, and it forces the technician to think.

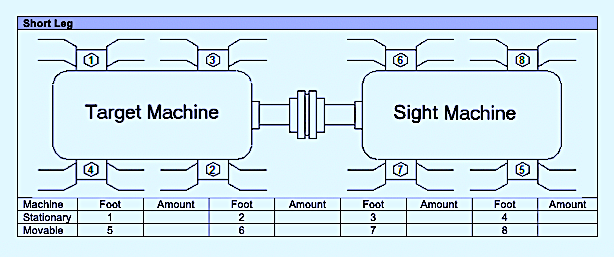

Another example we see is, “Was soft foot checked?” As we will find out in future articles, soft foot is one of the major causes of problems in machines and premature failures. Therefore, it should be thoroughly checked and corrected as part of the precision-alignment process. A complete record of the soft foot check and correction should be documented. The image below is an example of a soft-foot-related record form.

This type of form allows users to fully document the problem and plan to eliminate it going forward. The detail provided in this form, along with the rest of that data captured generates the vital history that can be used make future efforts more successful.

MAKE PAPERWORK EASIER

Of course, in today’s world the notion of making work harder is a non-starter. However, the way to ease the pain of paperwork is not to stop gathering the information.

Technology can be our friend here. There are apps and tablet-based systems that do more than capture, store, and manage all precision-maintenance data with ease: They will lead a technician sequentially through the job and even provide targeted help on specific tasks, if needed. Tactical and strategic metrics can also be automatically generated and tracked. This can save a significant amount of time and effort, resulting in better documentation and, in turn, an more sustainable program. Furthermore, all of this can be accomplished without sacrificing the quality of the information gathered.

FINAL THOUGHTS

Documentation is vital to the success of precision Maintenance. It sets expectations, captures results, and measures success. We have seen vibrant, valuable precision- maintenance programs wither and die in a very short period of time because they stopped documenting.

Next week we will move to a more technical subject: dealing with soft foot.TRR

ABOUT THE AUTHOR

Tim Dunton is the Director of Product Development and thought leader for Reliability Solutions, a UT-RMC training partner based in Northwest Florida. He has over 40 years of experience in vibration analysis and technical training related to the reliability of rotating machinery, including extensive work and qualifications in machinery troubleshooting, problem-solving, and condition-monitoring program design, implementation and operation. His background also includes significant experience in workforce development, curriculum development, instructional design, and Reliable Manufacturing. Dunton holds DTI Class 1 Certification, CMRP, and CMRT Certifications. Email: timdunton@reliabilitysolutions.net.

Tags: reliability, maintenance, availability, RAM, maintenance management, change management, workforce issues, skills development, training and qualification