by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Mar 6, 2021 | Lubrication Corner, Safety Matters, Workforce Issues

Safety in the workplace is paramount. Few people would disagree with this statement, especially working professionals in the maintenance and lubrication fields, who, for the most part, are well trained in this area. When it comes to the handling and transfer of...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 27, 2021 | Asset Management, Lubrication Corner

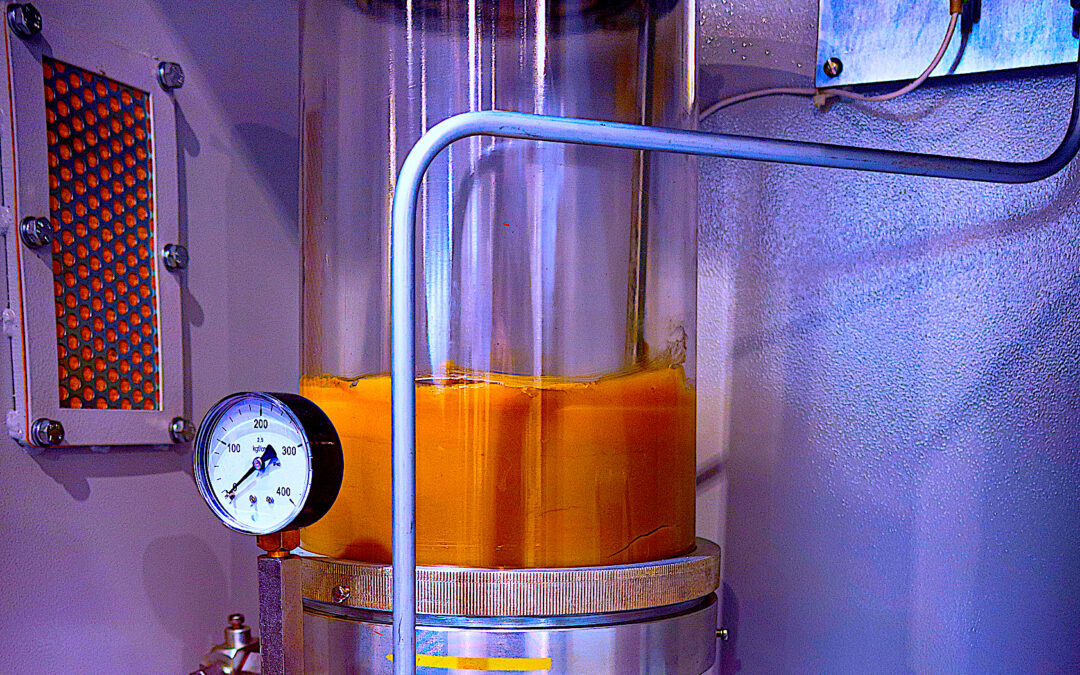

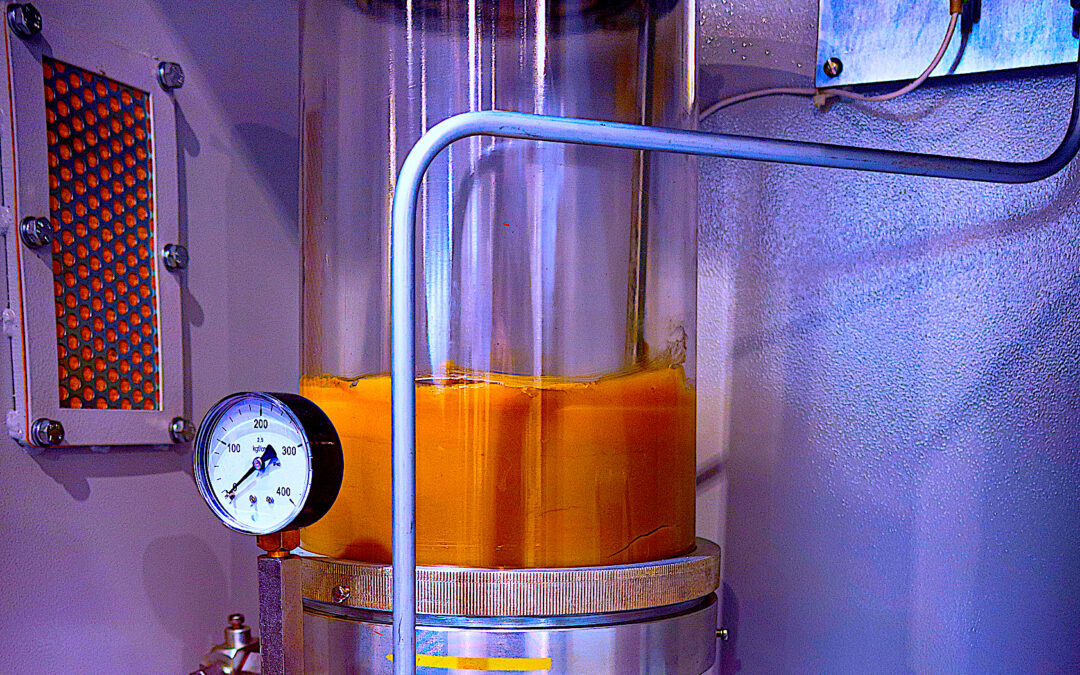

When was the last time you performed an interior physical inspection of your oil-system reservoirs? Is performing a reservoir cleanliness check (interior and exterior) part of a regular preventive maintenance (PM) checklist for all hydraulic,...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 13, 2021 | Asset Management, Lubrication Corner

Over the past year, one effect of COVID-19 has been to turn us into a population of stockpilers and hoarders of consumable products. As a result, many are now more aware of a consumable item’s “best before date,” found on most product packaging and labeling materials....

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 6, 2021 | Lubrication Corner, RAM Tools & Methods

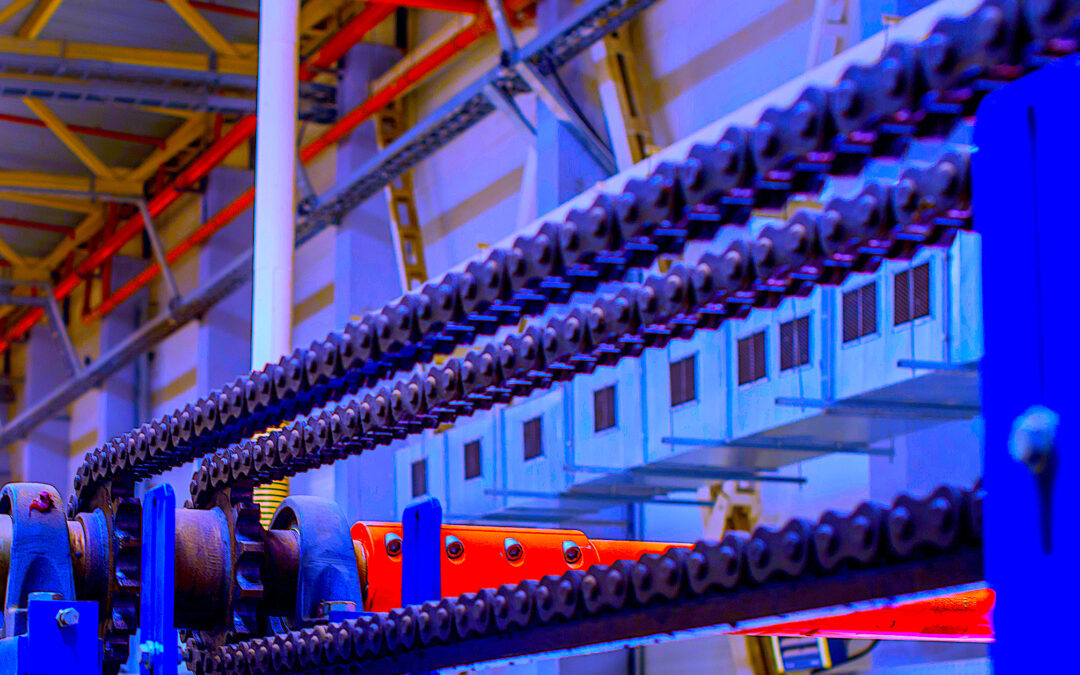

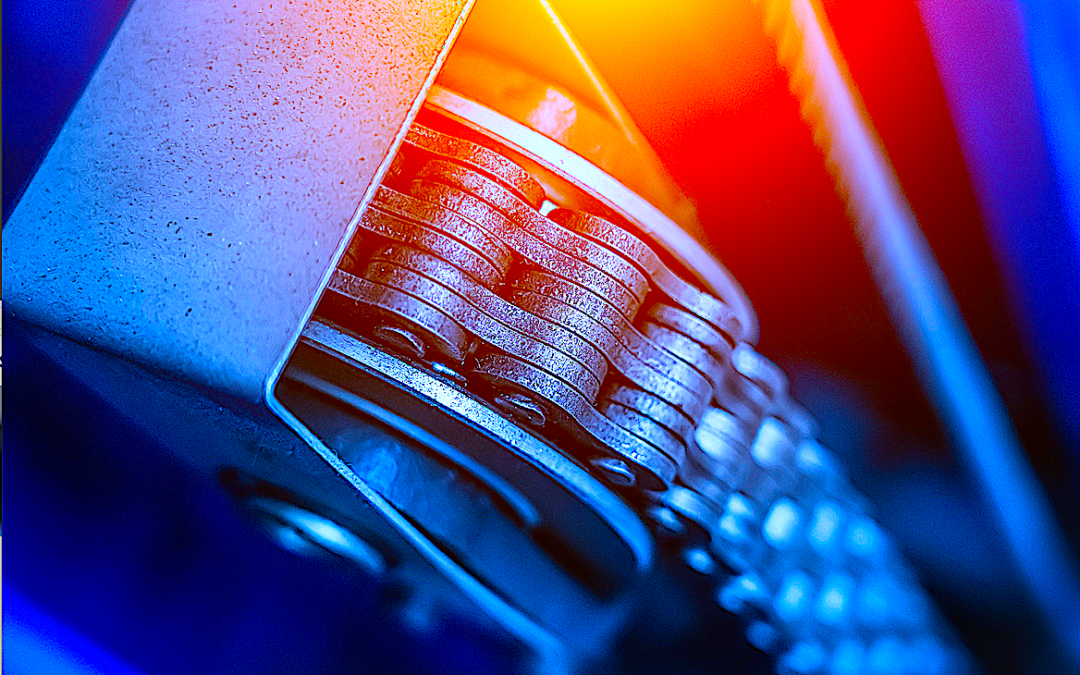

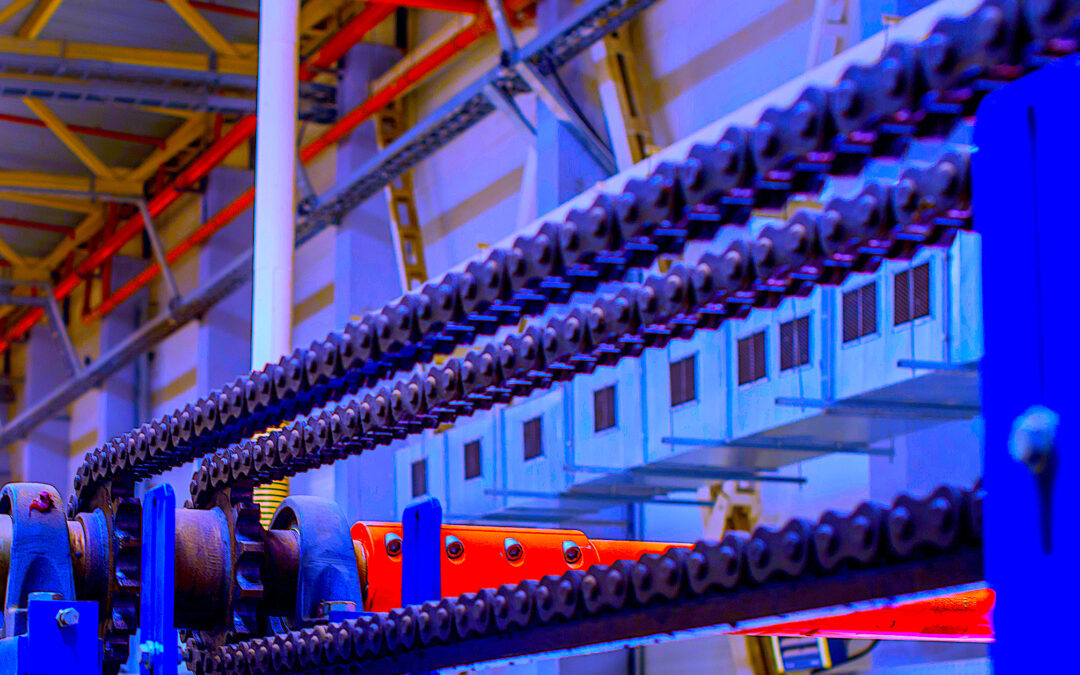

It is very easy to overlook the specialized needs of automated lubrication systems. In most asset-management-system and preventive-maintenance (PM) implementations, automated, centralized lubrication systems are often treated as integral components belonging to...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 16, 2021 | Lubrication Corner, Maintenance Management

A manufacturing client recently asked me a seemingly difficult question: Does a simple, universal, inexpensive, easy-to-implement maintenance strategy that’s capable of substantially increasing machine reliability and availability actually exist? My answer...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 19, 2020 | Asset Management, Lubrication Corner

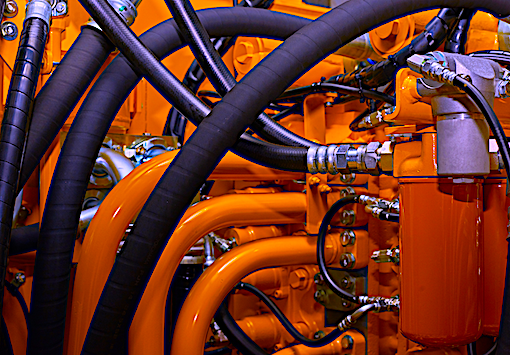

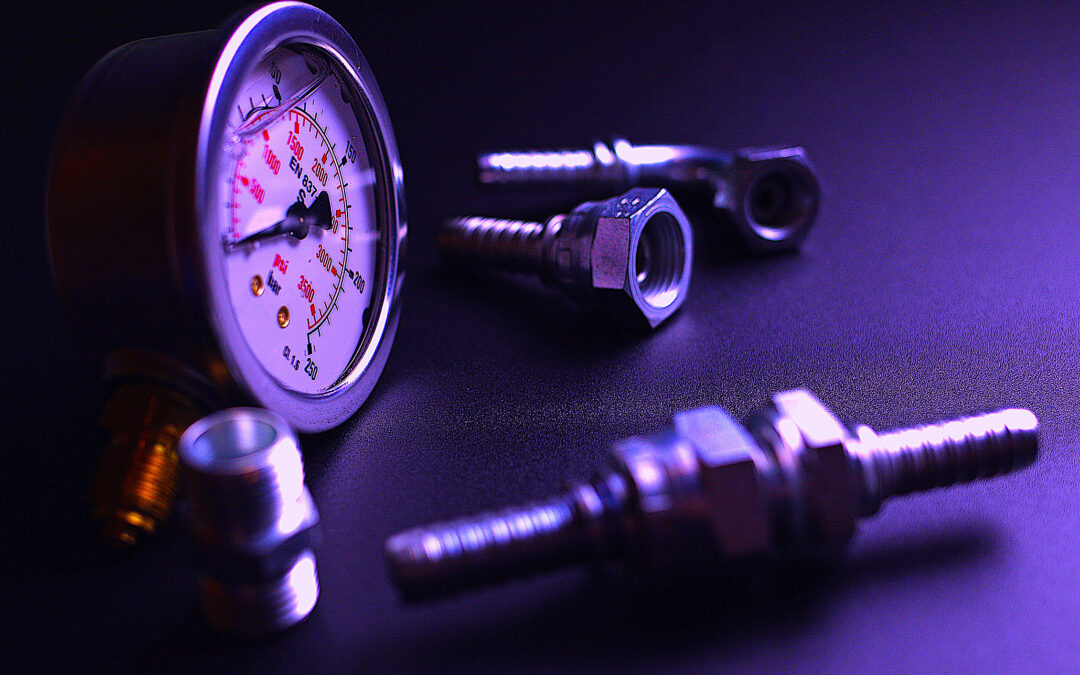

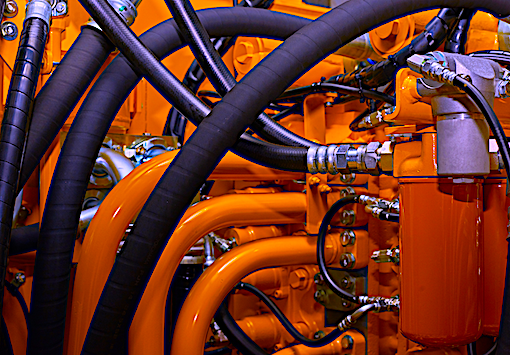

In my Dec. 12, 2020, article, “ Improve Hydraulic System Reliability For Just Pennies A Day” (see link below), I used the term “creep to failure.” It describes mechanical systems that continue to work, albeit inefficiently, for long periods of time,...

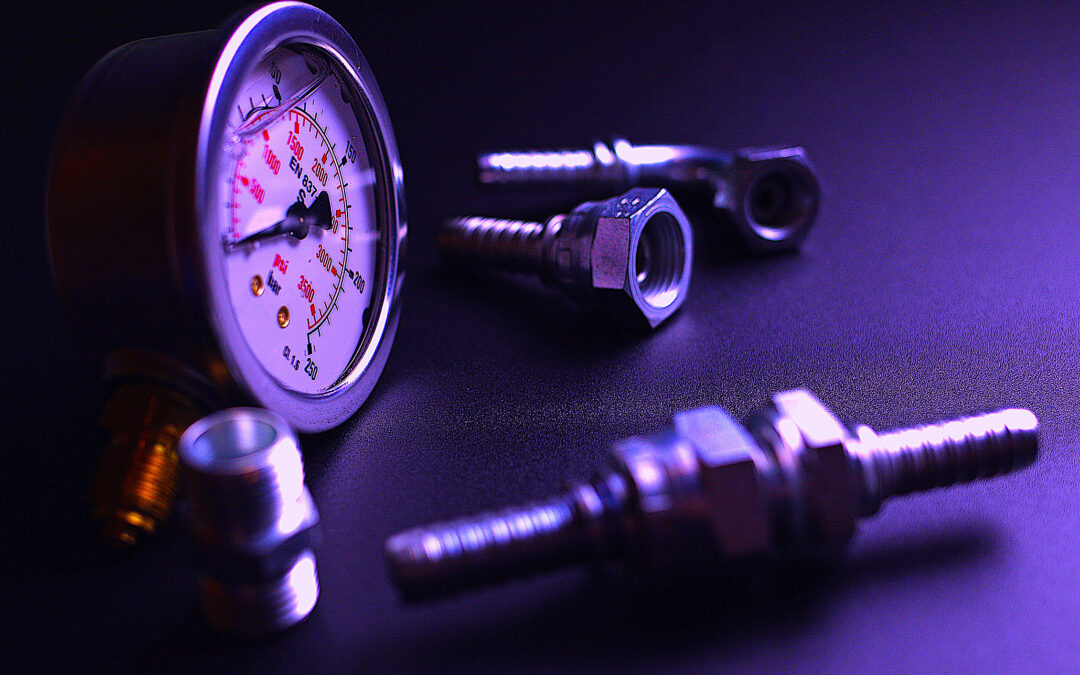

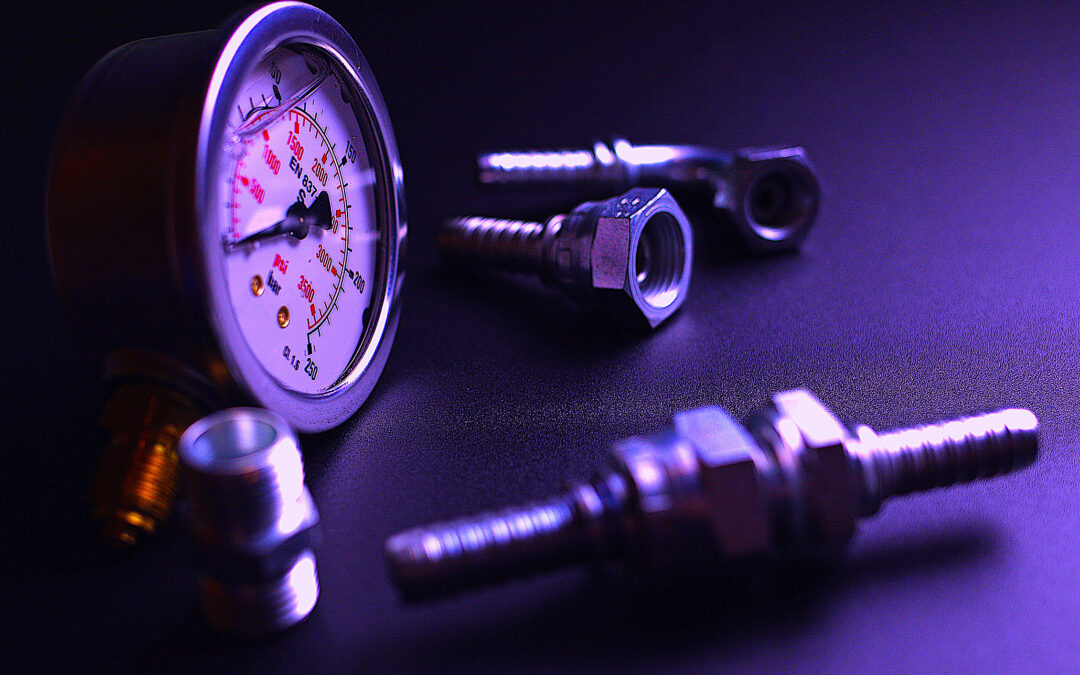

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 12, 2020 | Lubrication Corner, Maintenance Management

Despite their complexity, hydraulic systems are forgiving in nature. In most cases, they can perform well for a long time before any major or catastrophic failure occurs. Unfortunately, this “creep to failure” quality can promote apathy in production and maintenance...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Nov 21, 2020 | Asset Management, Lubrication Corner, The Sustainable Plant

The potential to reduce the environmental impacts of industrial operations with better management of parasitic frictional losses is well-documented. The science and technology associated with surfaces in relative motion, including friction, wear, and lubrication is...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 20, 2020 | Lubrication Corner, RAM Tools & Methods

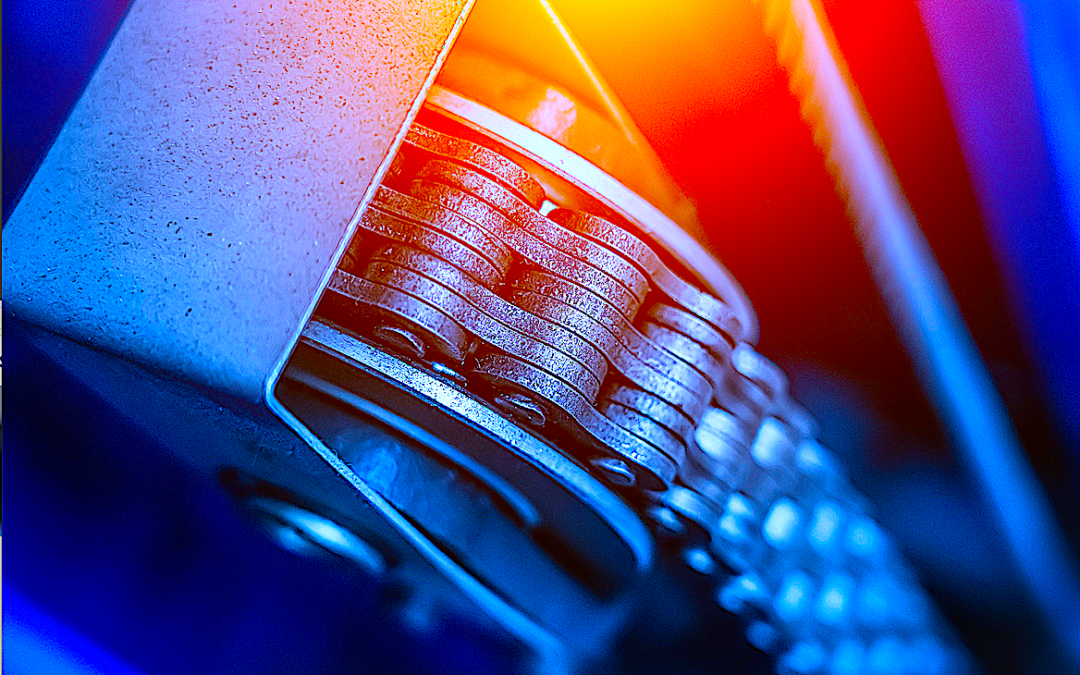

All bearings are destined to eventually fail. While ineffective lubrication practices are, arguably, the greatest contributing factor in such failures, the root cause(s) are rarely investigated due to production and maintenance turnaround demands. It’s...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 31, 2020 | Lubrication Corner, Planning & Scheduling

Talking about the weather is a national pastime. It would appear we are obsessed with it. Yet, many maintenance organizations are often poorly positioned to deal with the problems that weather changes pose for their facilities and machinery, especially when cold...