by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Aug 8, 2020 | RAM Tools & Methods

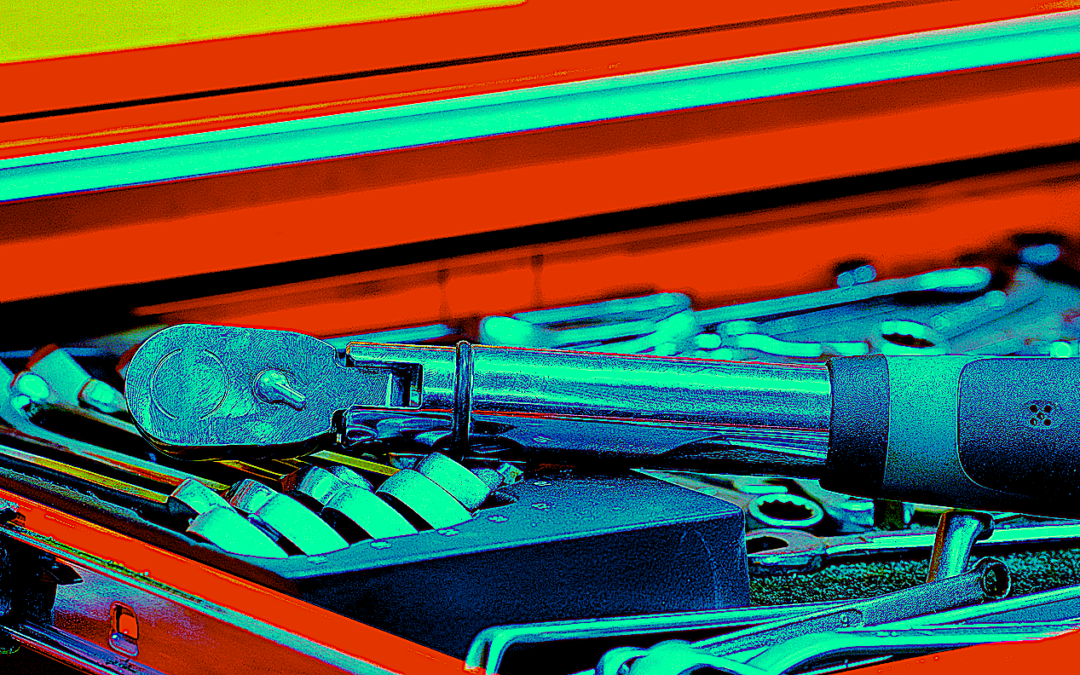

Have you ever spent time on the job looking for a specific tool you thought was in your toolbox? Have you ever cut yourself rummaging through a sea of tools trying to find a specific tool? Do you carry multiples of the same tool of differing quality that could cause...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 30, 2020 | RAM Tools & Methods

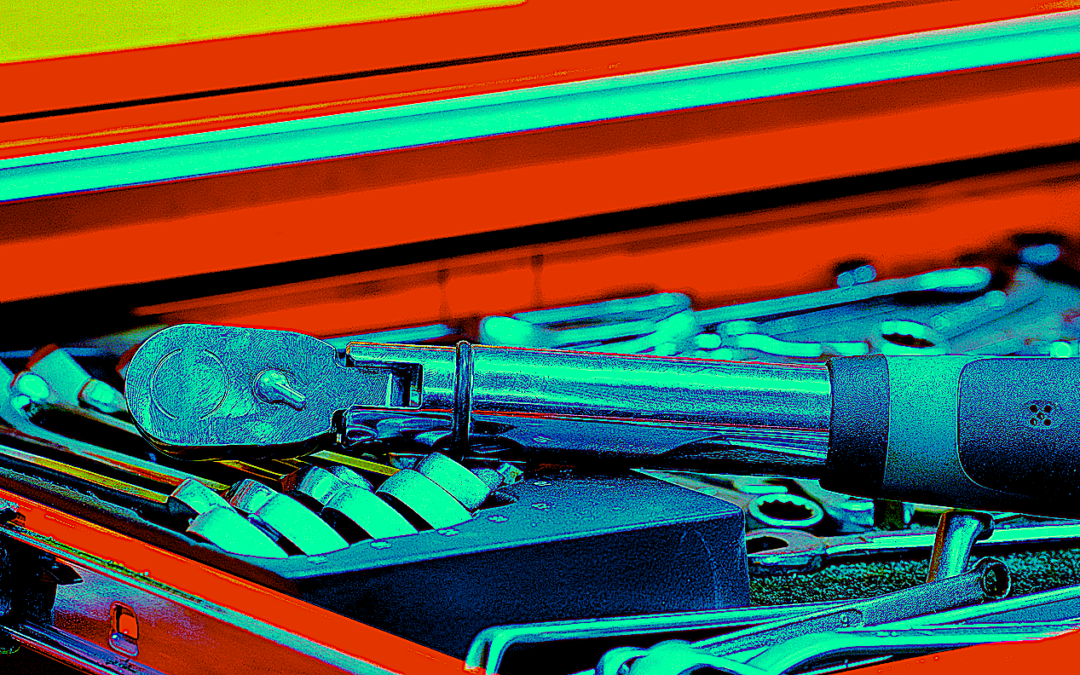

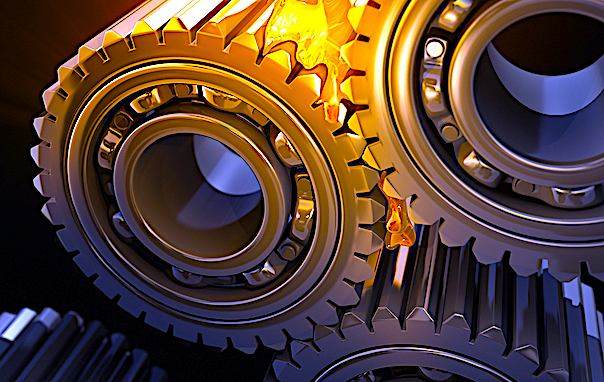

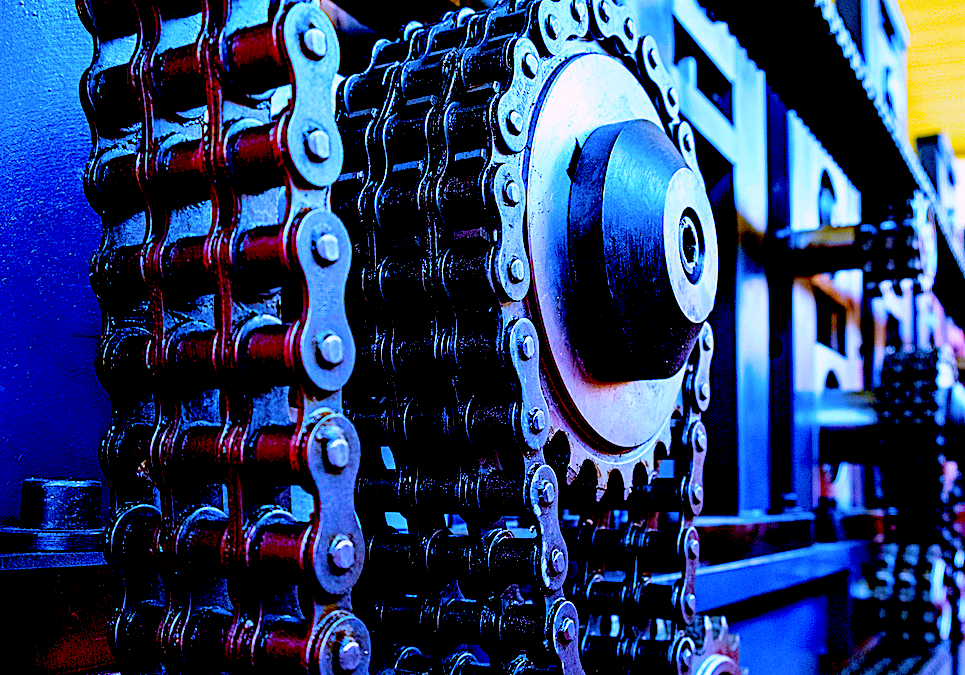

When maintained correctly, a set of roller-chain sprockets will outlive several chain replacements. Unfortunately, many maintenance departments operate under a policy that requires sprockets to be replaced every time the chain is replaced. While this is not...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 17, 2020 | RAM Tools & Methods

A maintainer’s personal spare time has always been a precious commodity. Most often, that time is divided into family responsibilities and homework assignments. And, if we’re re lucky, it’s balanced out with a bit relaxation time for pursuit of hobbies,...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 10, 2020 | Lubrication Corner

In 1966, at the height of the “swinging sixties” movement, the world of lubrication, friction, and wear finally received worldwide recognition as a scientific entity responsible for continued machine health and asset longevity. In retrospect, such recognition...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 3, 2020 | Lubrication Corner, RAM Tools & Methods

In the maintenance world, tools are indispensible in that they allow a maintainer to perform and complete work in a safe, consistent, and efficient manner (see article “Using the Right Tool for the Job”). When we think of tools, most will immediately picture a...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jun 28, 2020 | Newsletter Column, Plant Operations

For most businesses, the first and second quarters of 2020 will go down in the record books as their worst ever. With many non-essential-deemed manufacturing operations having to lay off or furlough much of their workforces and slow down or mothball their plants, the...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jun 19, 2020 | Maintenance Management, RAM Tools & Methods

Every good tradesperson knows that use of incorrect and inferior quality tools can result in inferior work. That said, no definitive study has been performed on resulting costs (the direct costs incurred through broken tools and broken fasteners, and indirect costs...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jun 5, 2020 | Planning & Scheduling, RAM Tools & Methods

Einstein once said there are three rules of work: “Out of clutter find simplicity. From discord find harmony. In the middle of difficulty lies opportunity.” Those rules seem quite applicable in today’s RAM arena. Work is an honorable pursuit...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | May 22, 2020 | Asset Management, Lubrication Corner

Throughout their working life, lubricants are subjected to a variety of negative influences that can include load induced shear stress, thermal degradation, water contamination, aeration, wear metal catalyzing, and contamination from dirt, chemicals, and mixing with...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | May 17, 2020 | Asset Management, Newsletter Column

It’s hard to dispute the level of adversity experienced by people and businesses during the extraordinary COVID-19 “lockdown” period. The good news, at least in the RAM arena, is that adversity also breeds opportunity. Thus, many maintenance departments...