by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 12, 2021 | Asset Management, Newsletter Column

When a new piece of equipment arrives at your plant, many crucial design decisions will already have been made to provide a machine that’s functional, safe, reliable, usable, manufacturable, and maintainable. Good design is no accident. It’s a result of an...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 5, 2021 | Newsletter Column, RAM's Human Factor

As a young design engineer, I worked under the tutelage of my mentor Tedeus (Ted) Monkiewicz. Within this arrangement, I often accompanied him on visits to customer operations that were experiencing machine warranty issues/problems. At each sites, I was not to speak,...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 28, 2021 | Asset Management, Lubrication Corner

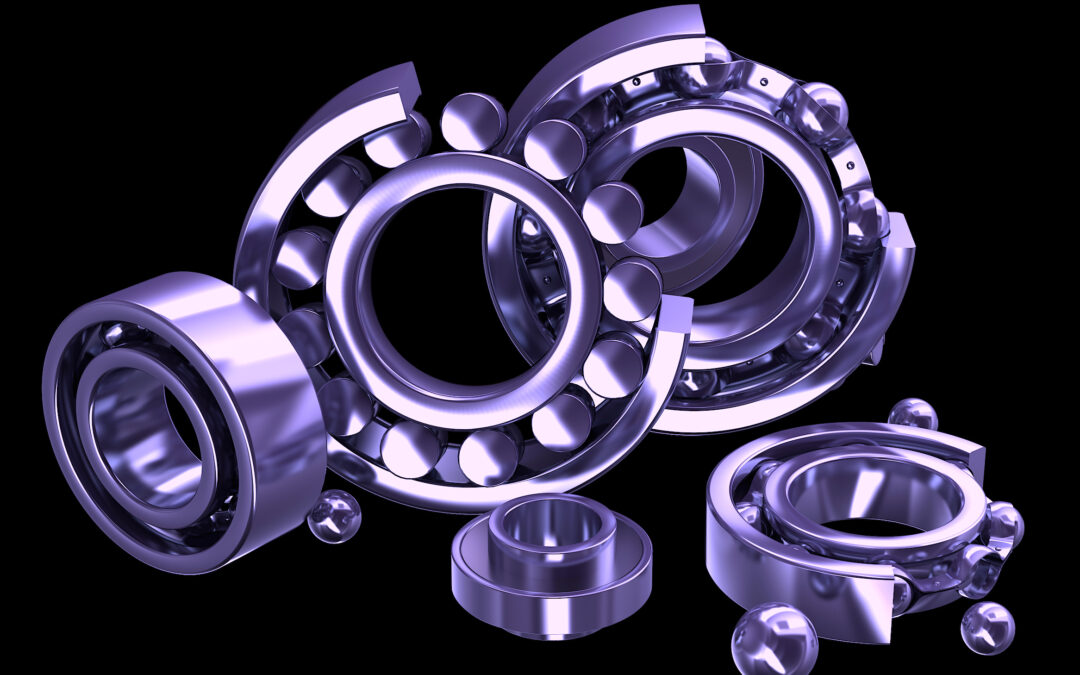

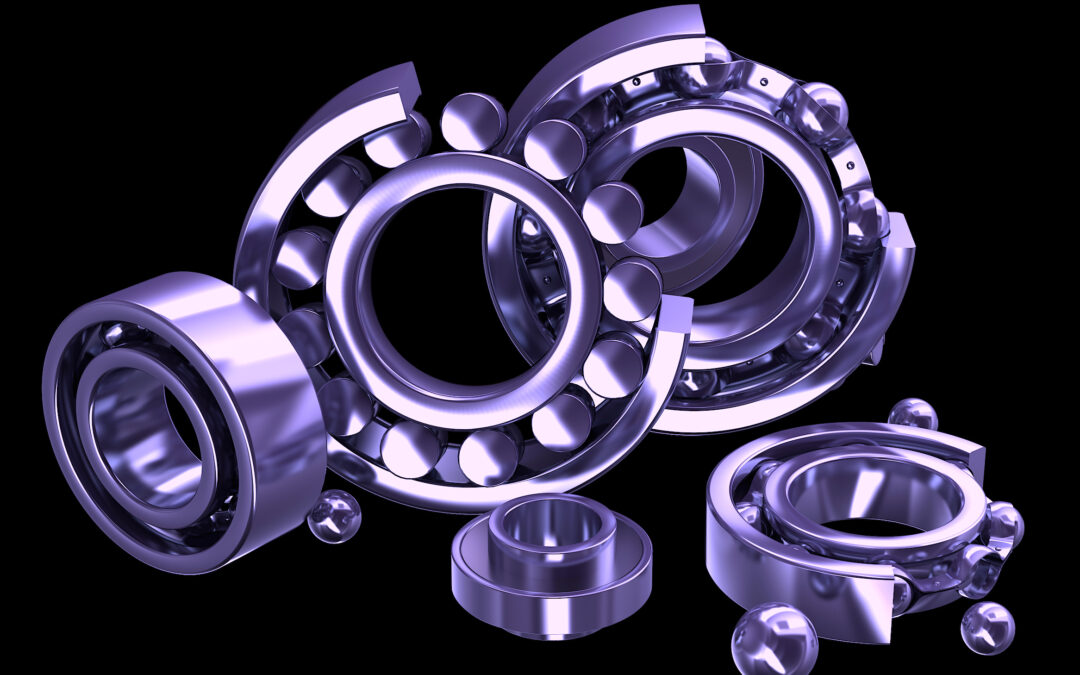

It’s very much a lubrication issue. When two metal surfaces are expected to interact, if they are not to weld to each other due to excess friction, they must be kept apart. That’s accomplished with a suitable film of lubricating oil. Some 50 years...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 21, 2021 | RAM's Human Factor

Ralph Waldo Emerson once wrote, “People only see what they are prepared to see.” That holds trues in the RAM arena. To be specific, when a problem is reported to the Maintenance department, it’s the job of the Planner to interpret the maintenance request...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 15, 2021 | Asset Management, The Sustainable Plant

Unless you’ve been hiding under a rock during the past few weeks, you probably are aware of the 2021 COP26 Climate Change Convention in Glasgow, Scotland, UK. Media sources are still being been bombarded with sound bites coming out of speeches at the event...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 7, 2021 | Newsletter Column, RAM Tools & Methods

To improve as individuals, teams, and Maintenance Departments, we first must look inward and examine ourselves through the eyes of others. Then, and only then, can true (and meaningful) change begin. Over the past 35 years, I have performed hundreds of...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 24, 2021 | Asset Management, Lubrication Corner

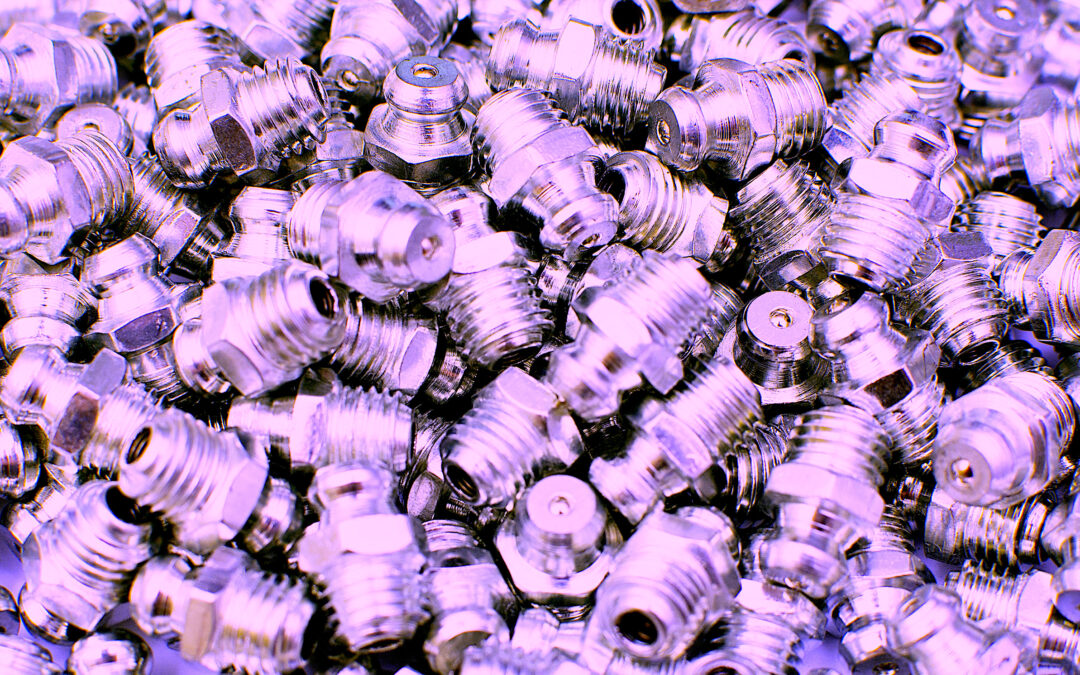

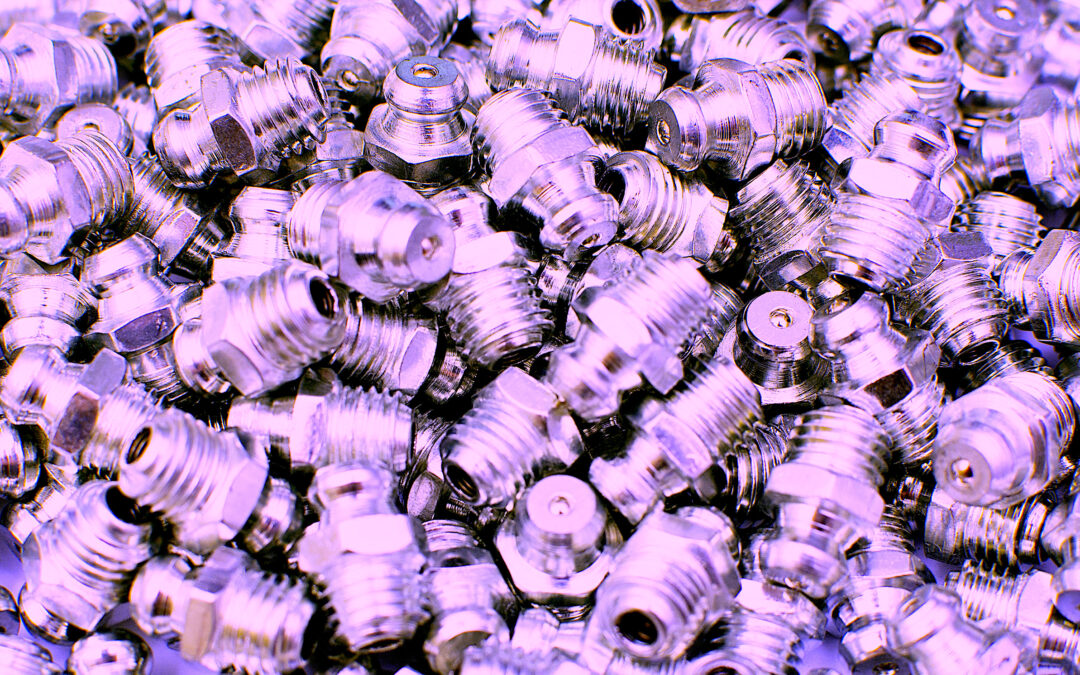

The lowliest and most ubiquitous device in the world of lubrication recently celebrated its centennial anniversary. Designed as a simple, yet efficient mechanical gateway device, the grease nipple has only one job: to connect to a manual grease-delivery gun and...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 17, 2021 | Asset Management, Workforce Issues

Today’s maintenance departments cannot, and do not, function autonomously. To be successful they must first recognize that success is based upon a series of integral partner relationships, set up and managed to provide mutual benefit for all partners. For many...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 10, 2021 | Newsletter Column, Planning & Scheduling

As we age, we soon recognize that “time” is the most precious resource we have. This finite resource is also the first currency by which all maintenance activity is controlled, managed, and measured to ensure that the client will receive first-time quality work, on...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Sep 27, 2021 | Asset Management, Planning & Scheduling

In the world of maintenance, we check and measure many things. We do so primarily to recognize and evaluate changes in the desired state of an item or system that’s being monitored and maintained by a preventive-maintenance (PM) program. Ideally, the PM...