by Bob Williamson, CMRP, CPMM, MIAM, Editor | Mar 7, 2021 | Asset Management, RAM's Human Factor

Making equipment reliable is more than an engineering project. More than precision maintenance. More than good data. And much more than many organizations consider at the onset. Reliability improvement requires many factors, elements, actions, and individual skill...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Feb 28, 2021 | Newsletter Column, RAM Tools & Methods

Mean time to repair/restore (MTTR) is the maintenance metric that summarizes the historical time taken to make necessary repairs and adjustments to return equipment to its desired operational state. In other words, “Fix it fast, fix it right.” When I ponder the...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Feb 20, 2021 | Asset Management, Electrical Reliability

Here’s a bit of history to ponder, or for RAM pros of a certain vintage, to vividly recall. “Drive 80 mph and freeze a Yankee,” was a popular bumper sticker in Texas during the 1973 – 1974 energy crisis. I lived in Northern Michigan at the time and...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Feb 14, 2021 | Newsletter Column, Plant Operations

Have you noticed shortages of food products, lumber, concrete, parts, supplies, and power tools, among other things? Many people are puzzled by shortages of what used to be common items in the marketplace. There are other shortages as well. COVID-19 and a volatile...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 31, 2021 | Maintenance Management, Newsletter Column

“Why do we need to fill out these work orders anyway? They’re just trying to micro-manage us. I’m not going to do it. Let’s just do things like we’ve always done.” Sound familiar? Maintenance work orders are often seen as an extra burden to maintainers, as well as to...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 24, 2021 | Plant Operations, Workforce Issues

These three words, “Made in China,” don’t have to foreshadow the downsizing or closing of plants, as they did in the past, but rather the reshoring of critical manufacturing. In fact, “Made in China” must be embraced as a wake-up call to our industries, our...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 17, 2021 | RAM Tools & Methods, Workforce Issues

What do COVID-19 recovery, robots, integrated automation systems, the Industrial Internet of Things (IIoT), RCM, re-shoring of jobs, and hiring talent have in common? Yes, they’re here, now, and they challenge many traditional ways of managing a business. But there’s...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 9, 2021 | Maintenance Management, RAM Tools & Methods

“Procedure-based maintenance” will be invaluable in this era of growing skills shortages and the need for greater machine reliability. Machine complexity, coupled with the impact of the skills crisis and business needs for improved performance, has created a situation...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jan 2, 2021 | Maintenance Management, RAM Tools & Methods

Many of the tens of thousands of preventive maintenance (PM) and repair work instructions I’ve reviewed over the decades have been sorely lacking in details. That means they’ve left a lot to the mechanics’ discretion. At the same time, many production...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Dec 20, 2020 | Maintenance Management, Newsletter Column

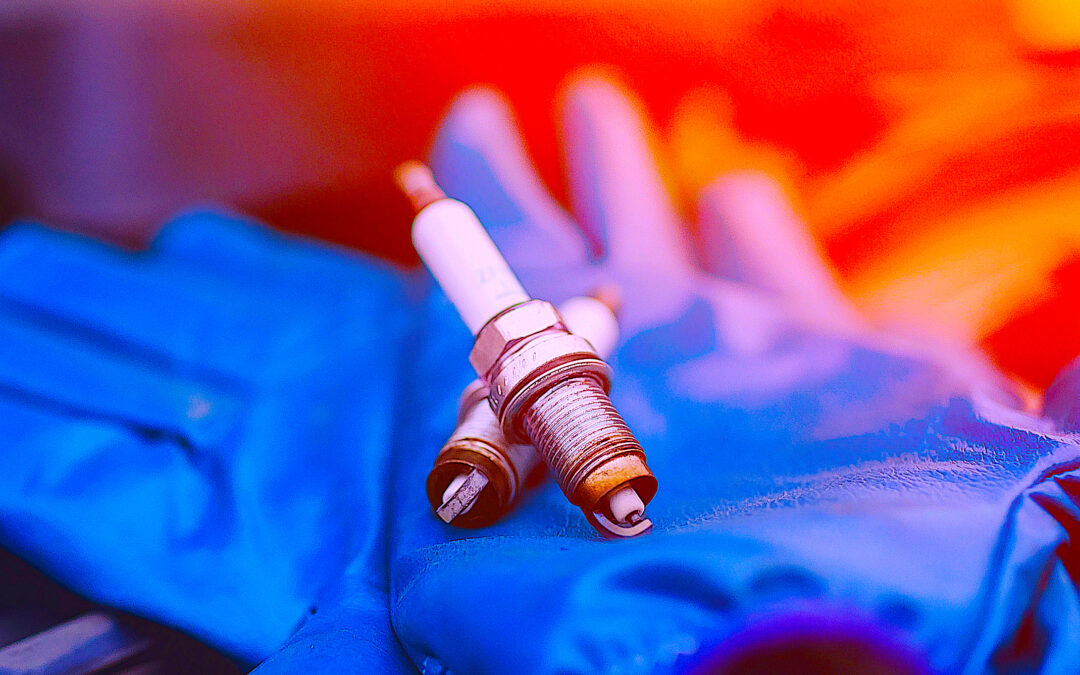

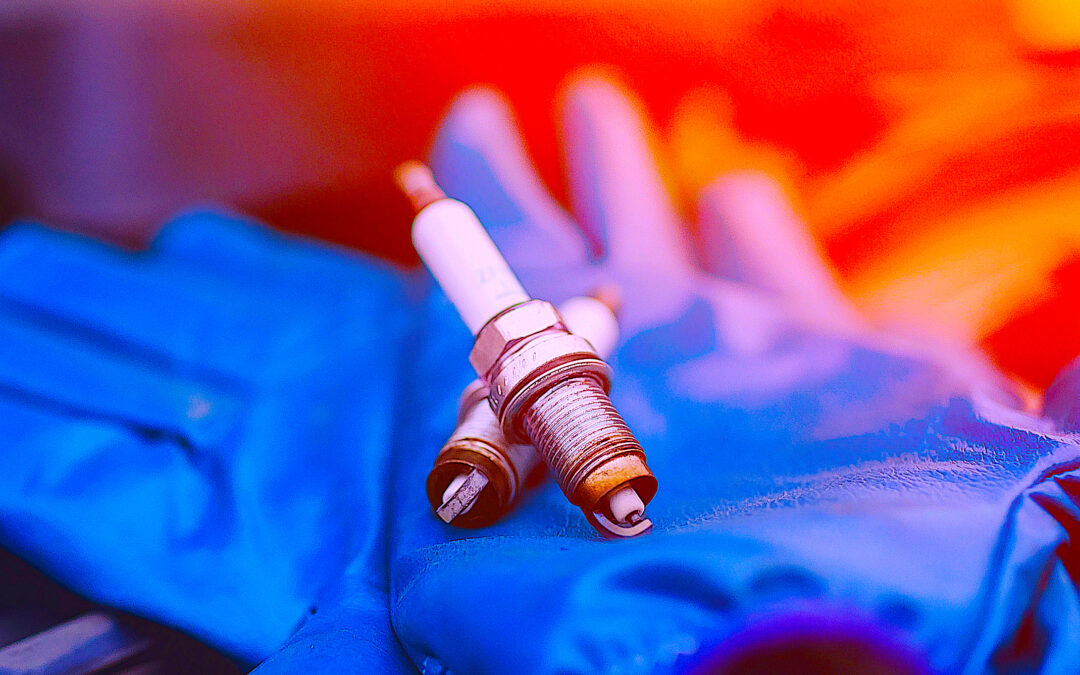

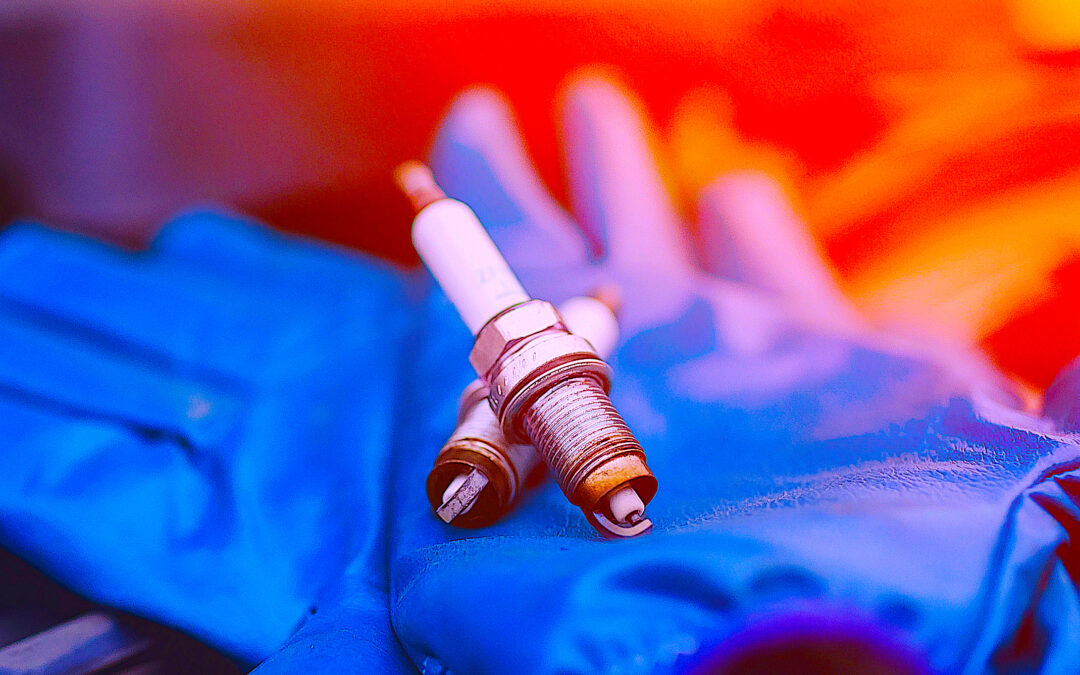

Reliable equipment depends on an alignment of the right things: The right application, operating conditions, duty cycle, operation, maintenance, replacement parts, input/output, performance data, and people following detailed work instructions. This column begins a...