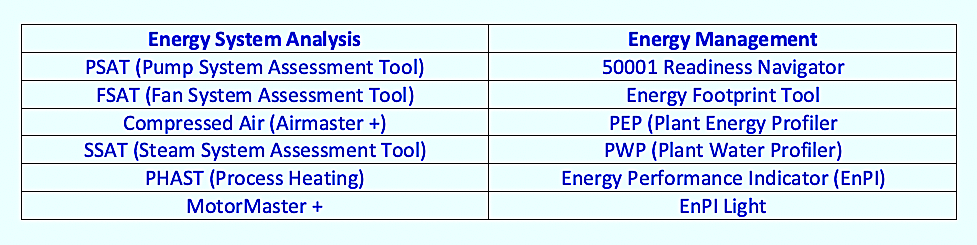

When determining the approach for assessing a facility, there are several decisions to make, including selection of independent software tools and guides. The U.S. Department.of Energy (USDOE, energy.gov) has developed a number of taxpayer-supported tools that review energy from a maintenance perspective. They incorporate excellent joint government, university, professional and trade association, national lab, and user guides to support improvements. For smaller companies that lack the resources to implement programs in-house, USDOE’s Industrial Assessment Centers (IAC) which are university programs, can provide walk-through opportunity assessments. Here’s a brief rundown of some of these offerings.

SOFTWARE TOOLS

USDOE offers free software-assessment tools that can be used to model, identify, and calculate payback analysis for different energy scenarios. These opportunities include:

The energy-system-analysis tools and some of the energy-management tools were combined into the MEASUR software tool suite, which also includes additional features. The MEASUR tool contains more than 40 calculators and system-modeling capabilities to analyze major energy systems, such as pumps, fans, compressed air, steam, and process heat. It also combines the findings and recommendations instead of individual models. Capabilities includes:

-

-

-

- creating assessments for major plant-support systems

- comparing multiple energy-saving projects in a single analysis

- prioritizing energy-improvement projects with quick, simple savings analyses

- general system diagrams for presenting system opportunities to decision-makers.

- displaying, printing, and exporting of information and graphics for presentations.

-

-

To access these tools, click here: https://betterbuildingssolutioncenter.energy.gov/better-plants/software-tools. More tools, for a variety of applications, are available on this website.

(NOTE: USDOE changes its website constantly, if the link does not work, search for the tools with your favorite search engine and select the .gov sites.)

GUIDEBOOKS

In addition to software tools, USDOE provides guidebooks and case studies to support energy efficiency, including recommendations on energy and physical-asset management combined. These resources are periodically updated to meet changes in the business environment and technologies.

To access these guidebooks, click here: Information Resources | Department of Energy.

INDUSTRIAL ASSESSMENT CENTERS (IACs)

Small and medium-sized manufacturers (SIC Codes 20-39) may be eligible for no-cost energy assessments by various university-based Industrial Assessment Centers. Among their many benefits, these opportunity assessments provided crucial hands-on experience to instructor-led student teams. The resulting reports, identify specific opportunities at each site, but only the specifics of those findings are added to the IAC database, not the specifics of the assessed location. An IAC specialist will assist smaller manufacturers in identifying where to focus their efforts, thus improving the payback of any programs that are implemented.

To qualify for an IAC assessment, the site must:

-

-

-

- be located within 150 miles of a participating university

- have gross annual sales below $100 million

- have fewer than 500 employees

- have annual energy bills of more than $100,000, but less than $2.5 million

- can have no professional in-house staff to perform assessments.

-

-

For more details and to find IAC locations, click here: Industrial Assessment Centers (IACs) | Department of Energy.

CONCLUSION

USDOE’s offers taxpayer-supported technologies, information, and resources to model, guide, and provide direct assessments for companies of all sizes. This article identifies several that are available at no cost to commercial and industrial facilities. Similar resources are also available in other areas of opportunity for businesses. We’ll cover some of them in upcoming articles.TRR

Click The Following Links To Read The Previous Three Parts Of This Reliability & Maintenance Opportunities Series

“Compressed Air System Efficiency” (Part 1)

“The Benefits From A Holistic Approach” (Part 3)

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, energy efficiency, energy management, pumps, electric motors, fans, compressed air, steam systems, water treatment, process heat, USDOE, plant audits, energy assessments, Industrial Assessment Centers, IACs