As noted in the first part of this short article series (Feb. 1, 2021, see link below), the idea of reducing cost and decreasing the environmental impact of a manufacturing or process plant by focusing on management of parasitic frictional losses is a very compelling one. And our ability to do so is very real.

This concluding article (Part II) provides specifics on moving from theory to practice in our quest to improve profits and reduce the environmental footprints in today’s plants. (I’ve touched on a number of these details in past articles.) Given their roles and responsibilities, RAM professionals can be key players in this important type of “thinking locally, acting globally” initiative (Tarantola, 2013).

Click Here To Read Part I (Feb. 1, 2021) Of This Article

YOUR TOP TACTIC: MECHANICAL/TRIBOLOGICAL BEST PRACTICES

Several relatively simple, easy-to-implement, and proven measures are available for managing parasitic friction-induced energy losses in industrial plants and factories. As a bonus to equipment owners, reducing energy consumption, and associated greenhouse gases (GHGs) by proactively managing parasitic frictional losses also minimizes wear and tear on the machinery and typically reduces unscheduled downtime.

To achieve those objectives, steps must be taken to minimize vibration, ensure smooth transfer between driving and driven machine components, and protect the integrity of the lubricant film that’s responsible for reducing friction. In essence, we want machines that are smooth, quiet, cool, and clean. When they are shaky, noisy, hot, and dirty, energy is being wasted due to parasitic friction. For most machines, a few simple measures can greatly reduce parasitic friction in mechanical systems, including the following:

♦ Precision fastening of machines to their bases and foundations.

♦ Precision alignment of shaft-driven mechanical drives.

♦ Precision dynamic balance of mechanical rotating assemblies.

♦ Precision alignment and tensioning of belts for belt-driven equipment to reduce slip.

♦ Proper selection, application, and management of lubricants.

♦ Proper fastening of fluid transfer systems to minimize leakage of energized fluids.

♦ Minimizing turbulence in fluid transfer systems by:

-

- selecting proper pipe-diameter for a given fluid flow rate and viscosity

- minimizing piping length

- minimizing pipe turns, especially turns greater than 30 degrees

- optimizing valve selection and placement

- selecting materials with smooth internal surfaces.

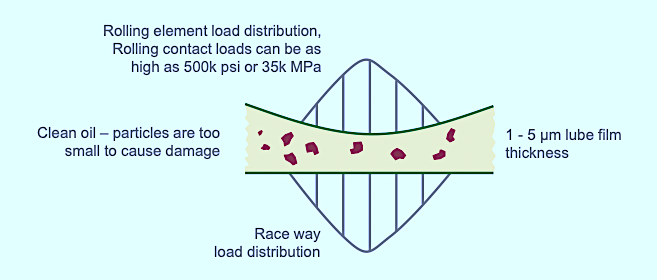

At a microscopic level, the transfer of energy in mechanical systems depends upon the separation of machine elements by a critical lubricant film that rarely exceeds 5 micrometers (µm), which is less than the diameter of a red blood cell (Fig. 1). The momentary loads on the critical lube film can reach 500,000 psi (35k MPa). Lubricating oil possesses a special property whereby its viscosity is elastic as a function of pressure. Under the load of operation, the increasing viscosity results in increasing film strength, one reason why oil is an excellent lubricant. However, the strength of this film has limits and can be compromised by lubricant contamination.

Fig. 1. A blood cell-sized lubricant film separates loaded machine surfaces,

which reduces friction, wear, and energy waste. (Source: Troyer, 2014-2020)

A machine, its base, and its foundation are generally intended to move as a single mass. Loose, missing and improperly tensioned fasteners create mechanical looseness, and wastes energy. Additionally, the different components of the machine, such as a motor, gearbox, and pump, must be precisely aligned to avoid wobbling.

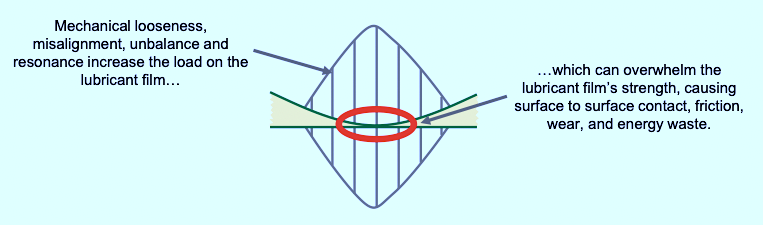

Likewise, rotating machine elements must be precisely balanced to assure that there is an even distribution of mass around the circumference of the rotating assembly. Looseness, misalignment, and unbalance all result in machine vibration that increases the loads on critical films. If the film strength provided by the lubricant is overwhelmed by vibration, surface to surface contact that leads to parasitic frictional energy losses and additional wear and tear on the machine (Fig. 2).

Fig. 2. Machine vibration creates frictional machine contacts

that lead to heat production and energy waste. (Source: Troyer, 2014-2020)

In many industries, pulleys and V-belts are employed to connect motor drives to fans, pumps, conveyors, crushers, and similar equipment. It is a common occurrence for the pulleys to be misaligned relative one another and for the belts to be improperly tensioned. Poor drive-belt management results in slippage and frictional energy losses. As an example, consider the details of a belt-slip study I conducted on eight conical crushers driven by 380-kW motors. Each operated at 80% of load, for 7,000 hours per year.

The drive systems of those conical crushers exhibited an average 15% belt-slip as opposed to a best-in class maximum of 2%. The frictional losses due to improper V-belt maintenance on these drives resulted in a loss of more than 2 million kWh per year (an equivalent of more than 2,500 mt of CO2-e annually). The findings of my study showed that elimination of those frictional losses would allow the plant to reduce operation from eight to seven crushers, with no loss of production.

In addition to managing sources of vibration that compromise the lubricant film, the lubricant film itself must be correctly selected to ensure that it possesses the correct physical, chemical and performance properties; be maintained in good condition; and be supplied in proper quantity.

Viscosity of the lubricating base oil is the most important lubricant-selection decision, because viscosity is what creates the hydrodynamic or elasto-hydrodynamic separation of the machine’s contacting surfaces. If the viscosity is too low, the lubricant will lack the film strength that is necessary to separate machine surfaces, leading to surface-to-surface contact-related frictional energy losses. However, if the viscosity is excessive, frictional fluid churning will produce energy waste. Additionally, the lubricant must be formulated with correct additives, especially friction-modifying additives that prevent metal-to-metal adhesion, in the event of incidental surface-to-surface contact (Fitch & Troyer, 2010).

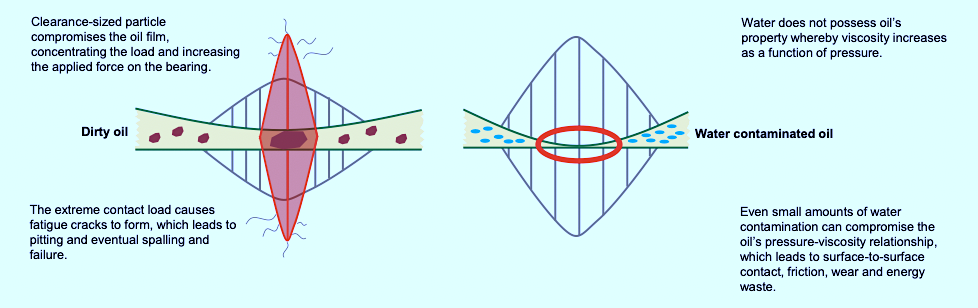

Another important aspect of lubricant health is contamination control. The most common contaminants are dirt particles and water, but engines also suffer from soot, antifreeze, and fuel dilution contaminants. Particle contaminants that are suspended in the oil can create millions of frictional microcontacts. Particles in the 5 to15 µm size range are particularly deleterious, because they are high in numbers, do not settle out of the lubricant easily, and are perfectly sized to bridge the lubricant film. This phenomenon creates significant stress concentration between the mating surfaces of mechanical systems. Recall that typical contact loads between contacting surfaces can reach 500,000 psi (35k MPa). If a particle concentrates that force to one-tenth of the surface area, the force is increased to 5 million psi (350k MPa). This produces a great deal of friction. Individually, these frictional microcontacts do not consume a great deal of energy, but collectively the losses become significant (Fig. 3).

Fig. 3. Particle and water contamination increase friction in mechanical systems. (Source Troyer, 2014-2020)

The presence of water contamination in the lubricant is similarly problematic. Water does not possess the same property of oil whereby its viscosity increases as a function of pressure. Likewise, when water has contaminated a lubricant, it compromises the oil’s pressure-viscosity relationship. This produces surface-to-surface contact, friction, energy waste and machine wear (Fitch & Troyer, 2020).

Proper sizing and design of fluid-transfer pipes and hoses are another opportunity to significantly reduce frictional energy losses. As a rule, it is desirable to minimize turbulent flow in piping and hosing systems. This is achieved by assuring that the inner diameter is adequate to comfortably accommodate the fluid-flow rate without producing excessive turbulence. For example, water flowing through a six-inch-inner-diameter pipe for 1,000 liner feet, at 600 gallons per minute requires nearly four times as much energy as the same flow through an eight-inch-diameter pipe and more than 12 times the energy required if the pipe has a ten-inch-inner-diameter. It is also advisable to minimize sharp turns in piping, particularly turns greater than 90 degrees, because they produce energy-consuming turbulence as well (U.S. Dept. of Energy, 2005).

While mechanical systems offer the greatest opportunity, improvements in the energy efficiency of electrical systems, especially related to electrical-current-induced heating (I2R losses), should not be overlooked (Penrose, 2014). These opportunities include:

♦ Selecting high efficiency motors. The IEC 60034-2-1 2014 Standard defines the classes for the energy efficiency of electric motors (the prime movers for most industrial facilities). Energy-efficiency categories include: IE1 – standard efficiency; IE2 – high efficiency; IE3 – premium efficiency; and IE4 – super-premium efficiency. A 75-kW IE1-rated 4-pole electric motor has a 92.7% efficiency. By comparison, the same frame-size motor that carries an IE4 rating is 96% efficient. Selecting IE4-rated electric motors significantly reduces a plant’s energy footprint.

♦ Designing and sizing electrical circuits to minimize electrical heating. When undersized, electrical circuits produce resistive heating due to I2R losses due to electrical eddy currents. Properly sizing circuits and selecting low impedance conductors reduces electrical heating losses. Additionally, minimizing the distance between stepdown transformers and the point of electrical energy use reduces resistive heating losses (Penrose, 2014).

♦ Utilizing variable frequency drives (note: AC to DC conversion and DC to AC inversion losses must be considered). The efficiency of many industrial processes is improved when the speed can be varied. Variable frequency drives enable this by converting 60 Hz AC electricity into DC electricity and then inverting the DC electricity into a modified square-wave at the desired frequency. For example, a motor that runs 1800 rpm at 60 Hz turns 900 rpm if the frequency of the power is modified to 30 Hz. The ability to control speed through frequency can have a big impact on energy consumption. The conversion and inversion processes do result in some heat generation and associated energy loss. This must be evaluated relative to the energy savings associated with variable speed control.

♦ Minimizing voltage and current harmonic distortion. Harmonic distortion refers to distortion of the base power sinewave. In North American, our AC electric power is delivered at a frequency of 60 Hz. Harmonics represent voltage at harmonics, or multiples of the base frequency such as 120 Hz, 180 Hz, etc. These voltages distort the 60 Hz voltage and force machines to compensate with current. Increasing current produces electrical heating and energy efficiency losses (Penrose, 2014).

♦ Maintaining electrical balance in three-phase electric motors (phase to phase). Most industrial electric motors receive AC electricity in three phases separated by 120 degrees around the circumference of the motor’s stator. This enables the motor to smoothly convert electrical energy into mechanical energy. These three phases must be balanced in terms of voltage, current, resistance and inductive performance. A phase-to-phase voltage imbalance creates an increase in the required current passing through the lagging phases. Increased current results in increased heat. For example, a 3.29% voltage imbalance produces a 20% increase in the temperature of the electric motor because of electrical heating.

BOTTOM LINE

To be clear, solving the world’s energy and related climate-change challenges isn’t a quick fix. But, as I’ve said and written many times before, energy management in the manufacturing and process industries offers an excellent opportunity to create a big impact without requiring significant lifestyle changes for the population at large.

By implementing recognized and proven best practices for energy management in our industry sectors (and with no loss of production throughput), total energy consumption in the United States can be reduced by more than 6%. With some investment in practical, achievable energy-efficiency technologies, this percentage can potentially be increased to over 15%.

Managing parasitic frictional losses is a great starting point. It reduces a site’s energy bill, reduces wear and tear on its machines, and, very important, reduces the plant’s GHG impact. That’s an all-around win.TRR

REFERENCES USED IN PREPARATION OF PARTS I & II

Fitch, J. and Troyer, D. (2010). Oil Analysis Basics. Noria Publishing, Tulsa, Oklahoma USA. ISBN 0-9675964-1-7.

IEC 60034-2-1 (2014. Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicle. International Electrotechnical Commission. Geneva, Switzerland.

Jost, H.P., (1966). “Lubrication (Tribology) – A report on the present position and industry’s needs.” Dept. of Education and Science. London, UK: H. M. Stationery Office.

Jost, H. P. & Schoefield, J. (1981). “Energy Saving through Tribology: A Techno-Economic Review.” Proceedings – Institution of Mechanical Engineers, 195(1), 151-173.

Penrose, H. (2014). Electrical Motor Diagnostics, 2nd Edition. Success by Design Publishers. ASIN B00RW3A1AM.

Tarantola, D. (2013). “Thinking Locally, Acting Globally?” American Journal of Public Health (1971), 103(11), 1926.

Troyer, D. (2014-2020). Focus on FLAB with Proactive and Precision Maintenance – Coursebook. Sigma-Reliability Solutions/T.A. Cook Consultants.

Troyer, D. (2020). “Look to Tribology to Reduce Climate Change Impact.” The RAM Review. 21 November. https://theramreview.com/look-to-tribology-to-reduce-climate-change-impact/. Accessed 11 December 2020.

U.S. Energy Information Administration (2019). U.S. energy facts explained. https://www.eia.gov/energyexplained/us-energy-facts/. Accessed 07 Dec. 2020.

U.S. Energy Information Administration (2020). U.S. Energy-Related Carbon Dioxide Emissions, 2019.

U.S. Energy-Related Carbon Dioxide Emissions, 2019 (eia.gov).

U.S. Dept. of Energy (2005). Energy Tips – Pumping Systems: Reduce Pumping Costs through Optimum Pipe Sizing. Pumping Systems Tip Sheet #9, October. Reduce Pumping Costs through Optimum Pipe Sizing: Industrial Technologies Program (ITP) Energy Tips – Pumping Systems Tip Sheet #9 (Fact Sheet). Accessed 11 Dec. 2020.

U.S. Dept. of Energy (2007). Mining Industry Energy Bandwidth Study. Industrial Technologies Program. https://www.energy.gov/sites/prod/files/2013/11/f4/mining_bandwidth.pdf. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017a). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Advanced High Strength Steels (AHSS) Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-advanced-high-strength-steel-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017b). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Aluminum Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-aluminum-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017c). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Cement Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-cement-manufacturing. Accessed 05 December 2020.

U.S. Dept. of Energy. (2015a). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Chemical Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-chemical-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017d). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Food and Beverage Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-food-and-beverage-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017e). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Glass Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-glass-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2015b). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Petroleum Refining. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-petroleum-refining. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017f). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Plastics and Rubber Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-plastics-and-rubber-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2015c). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Pulp and Paper Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-pulp-and-paper-manufacturing. Accessed 05 Dec. 2020.

ABOUT THE AUTHOR

Drew Troyer has 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 250 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees, and is Master’s degree candidate in Environmental Sustainability at Harvard University. Contact him directly at 512-800-6031 or dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, climate change, energy efficiency, tribology, mechanical systems, precision maintenance, vibration, fasteners, lubrication, alignment, balancing, FLAB