Data-Driven Decision Making In Asset Management: An Interview With Dr. Ajith Parlikad Of IoM Cambridge

A plant’s transition to capturing the right equipment-data and creating the right data models may take time, effort, and investment, but it’s well worth it. In this interview,, a noted UK-based expert puts the task into perspective.

Supply-Chain Shortages? Thoughts On Filling The Pipeline

Equipment and process reliability and availability depend on a reliable supply chain, which isn’t a given today. Understanding the root causes of various shortages can help our industries recover.

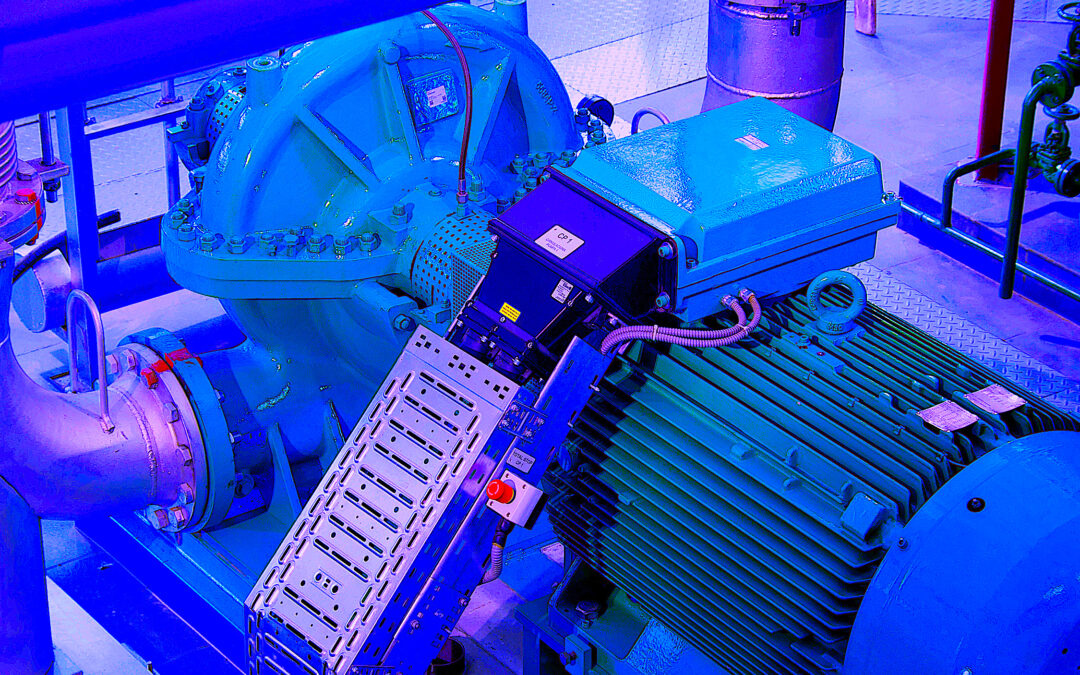

Smart Safety Devices For Smart Manufacturers

Rockwell Automation has introduced a pair of new solutions for enhancing safety and productivity in plants.

In Perspective: USDOE’s Study Of Electric Motor Systems, 2021 Edition (Part I)

USDOE has begun rolling out its new “U.S. Industrial and Commercial Motor System Market Assessment Report.” It’s very different from the first (1996) edition. This article begins explaining how and why.

Do Lubricants Have A Shelf Life?

Industrial lubricants rarely come with a specified “best before date.” This fact, though, shouldn’t stop sites from implementing strategies to keep these products going strong and delivering as designed.

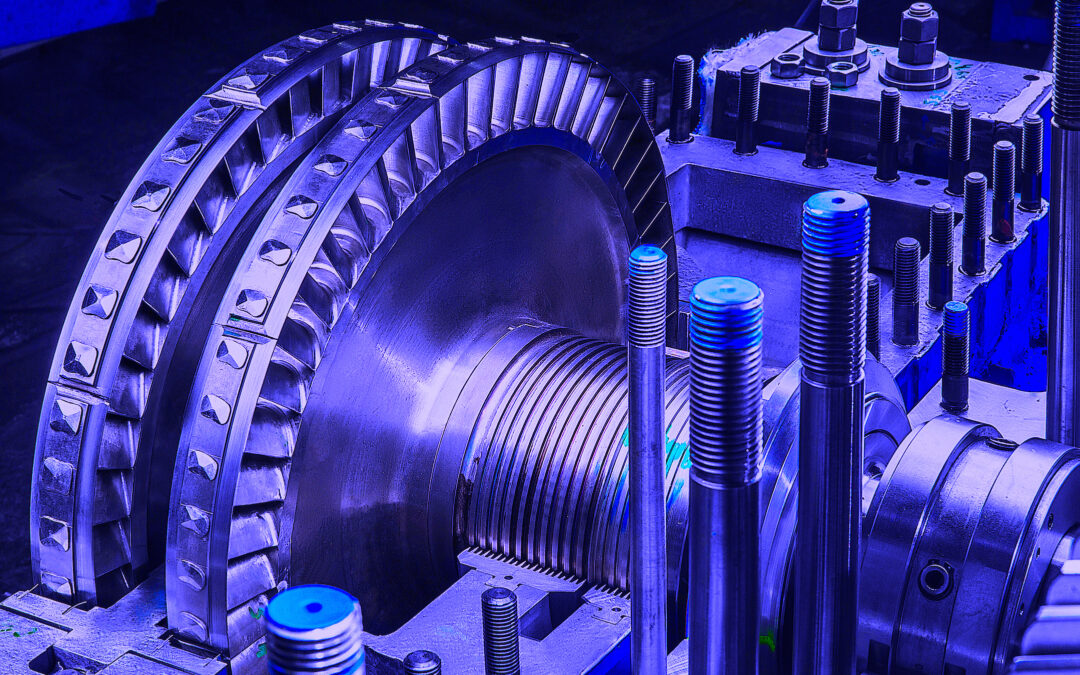

Consider Your Overspeed-Protection Options

Checking and possibly re-calibrating mechanical overspeed-trip devices on small turbines is an important, but often neglected annual PM task in plants. Well-engineered, reliable, electronic OSP systems spell relief.

Condition-Based Maintenance For Your Robots

ABB’s newly launched service offering is said to improve management of sites’ fleet and individual robots.

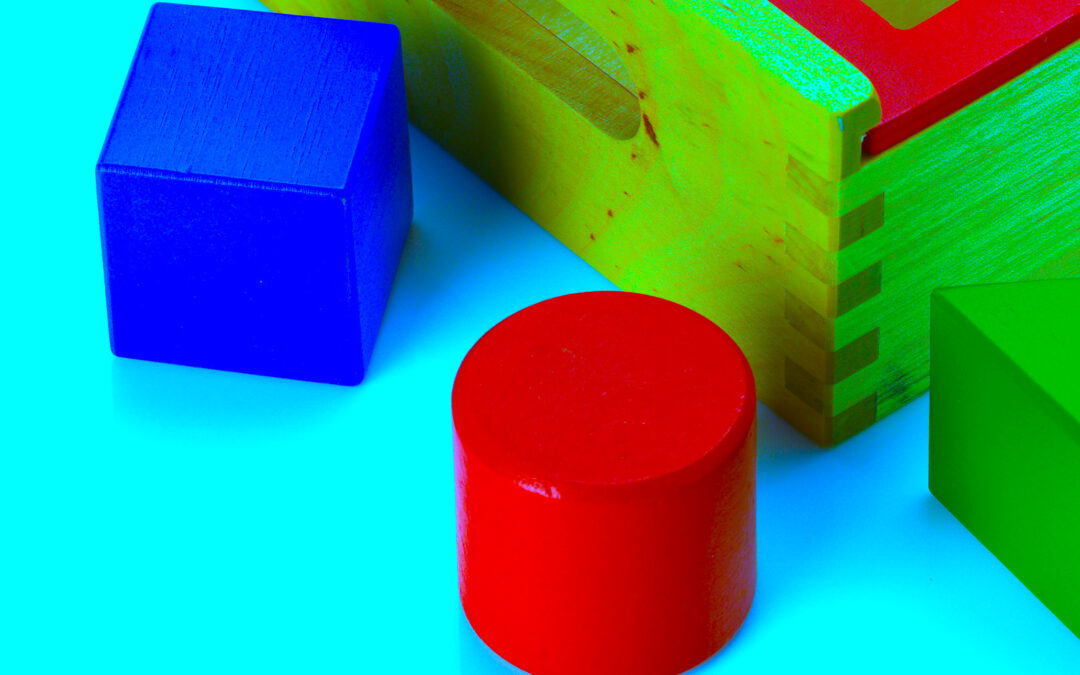

A Lesson From Shapes, Holes, And Experience

People and equipment don’t always operate as intended and, as a result, trouble can ensue. The author uses what’s been characterized as an “impossible to watch” video plus a personal experience to make his point.

Reducing Industrial Climate Impacts: Manage Parasitic Frictional Losses (Part II)

Solving the world’s energy and related climate-change challenges isn’t a quick fix. But ensuring adherence to mechanical and tribological best practices throughout industry is a big step in the right direction.

Frequency Of Infrared Inspections For Electrical Equipment

Historically, accepted industry practice has recommended annual infrared inspections of electrical equipment. Various site-specific conditions, though, could mean more frequent inspections are in order.