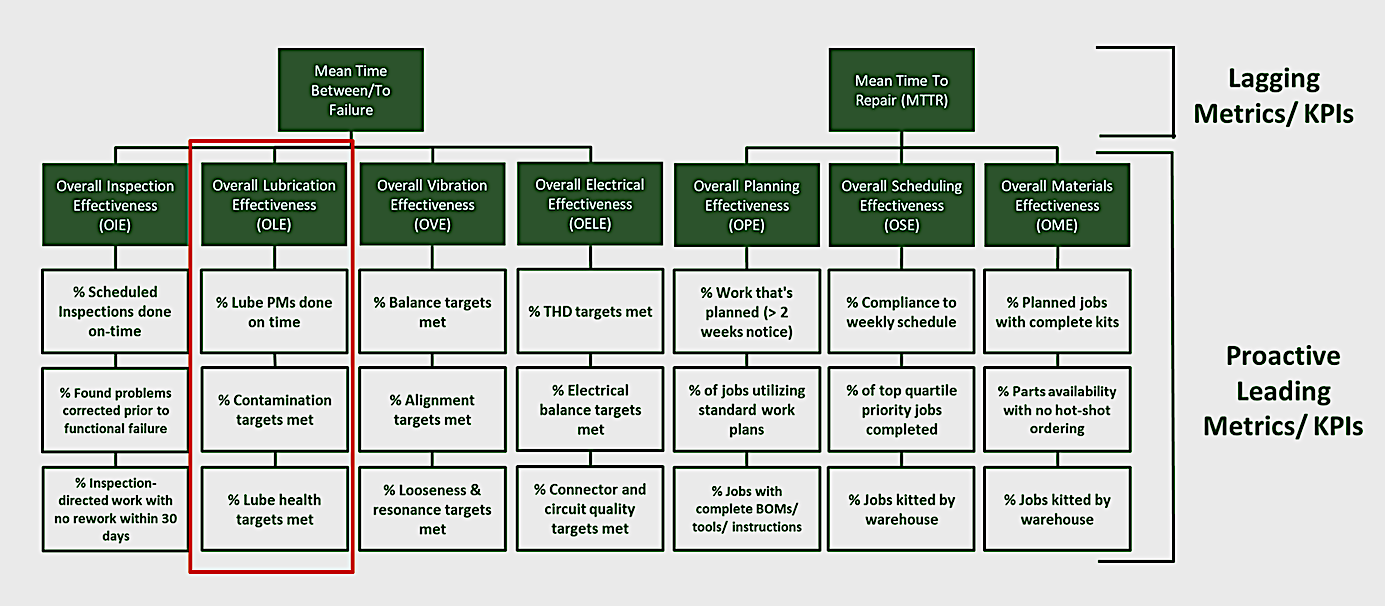

This week, I continue my multi-installment focus on leading metrics that help drive proactive behaviors with a discussion of Overall Lubrication Effectiveness (OLE). It builds upon my May 29, 2021, article for The RAM Review (see link below) on Overall Inspection Effectiveness (OIE).

Along with its companion leading metrics illustrated in Fig. 1, OLE is intended to drive proactive behaviors on the plant floor to ensure that the lubricant and lubrication process are effectively protecting machine components from the effects of abrasive, adhesive, fatigue, and erosive wear, and other performance-degrading mechanisms. Ultimately, by managing important root causes of failure, Overall Lubrication Effectiveness drives up Mean-Time-Between/To-Failure (MTBF/MTTF), which is our goal.

Fig. 1. Overall Lubrication Effectiveness (OLE) is a leading indicator

that drives proactive behaviors, which, in turn drive asset reliability.

WHAT OLE IS AND WHY IT’S IMPORTANT

The lubricant is the life blood of the machine. It provides a lubricant film that rarely exceeds five microns in thickness (about the diameter of a red blood cell) that is responsible for separating machine component surfaces and serves to reduce friction and wear. It’s also essential for controlling ingested contaminants and generated heat. In hydraulic systems, it’s the mechanism by which for and motion are transferred to accomplish work. Effective lubrication is crucial in managing the reliability of a site’s equipment assets.

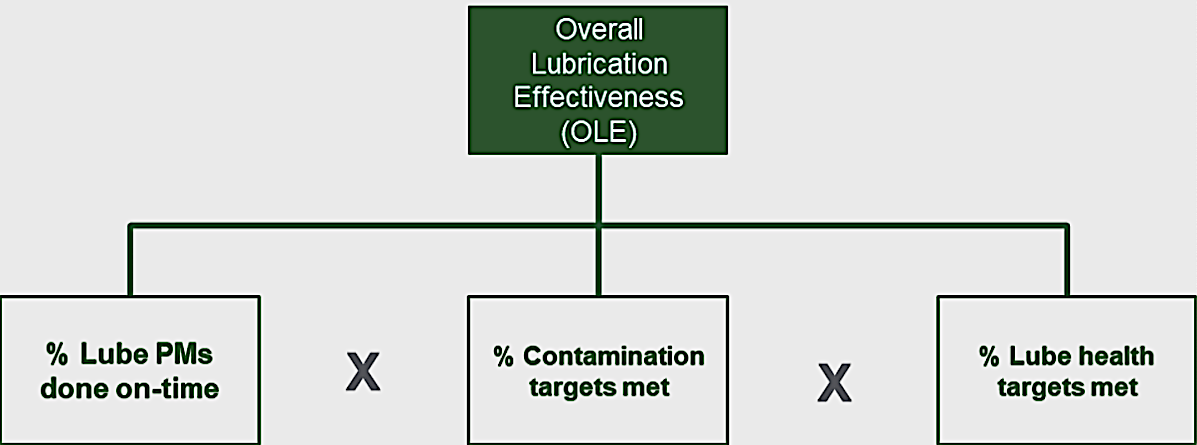

OLE is calculated by multiplying the following three factors (Fig. 2):

1. Percentage of lubrication PMs that are done on time.

2. Percentage of contamination targets met.

3. Percentage of lubricant and lubrication health targets met.

Fig. 2. The simple formula for OLE, which is the product of multiplying

the ‘behavioral inventories’ for the three input factors.

As we do with Overall Inspection Effectiveness, think of each of the three OLE components/metrics as an inventory process. We’re simply adding up the complying events and dividing by the total.

1. Lubrication PMs Completed on Time

Lubrication PMs include greasing bearings; performing time- or condition-based oil changes, changing filters and performing periodic decontamination, checking lube levels, and topping up as appropriate; monitoring lubricant temperature, pressure, and pressure-differential across filters; taking representative samples for oil analysis; inspecting lubricant-film quality for greased bearings using surface-borne ultrasonic analysis, and a host of other tasks.

Lubrication PMs are time-sensitive: They must be done on time. The Lubrication PMs completed on-time metric is binary, and quite simple to calculate. It’s the number of lubrication PMs scheduled for a given week and completed in that same week, divided by the total number of lubrication PMs scheduled for the week. If a PM is scheduled for a certain week, but we elect to push it into the next week, it’s not compliant. And if this week’s PM is completed nextweek, it doesn’t count as a PM completed next week (it’s removed from the equation). This may seem like a harsh interpretation of PM compliance, but precision maintenance demands rigour in completing time-sensitive tasks.

2. Contamination Targets Met

Contamination in the form of particulate, water, glycol/anti-freeze, soot, fuel, air, and excessive heat are the scourge of lubricated and hydraulic systems. The percentage of contamination targets met, like the percentage of lube PMs done on-time, is binary and simple to calculate. Based upon the most recent oil-analysis report, we inventory the number of machines that have no alarm condition for particle contamination (e.g., ISO 4406 cleanliness code), water contamination, glycol/antifreeze, soot (engines), or fuel dilution (engines) and divide that by the current number of machines included in the oil-analysis initiative.

Excessive heat and air are often-overlooked contaminants in lubricated and hydraulic systems. Heat accelerates that rate at which lubricants oxidize, seals and elastomers, thermally degrade and a host of other chemical processes. As a rule of thumb, a 10 C (18 F) increase in temperature doubles the rate of most chemical reactions. Compliance on lubricant temperature in the metric is simply the number of machines that are at or below their target temperature divided by the total number of machines for which temperature is being monitored. The monitoring can be accomplished with in-line/on-line sensors or gauges or with walkaround devices such as a non-contact pyrometer. The temperature component includes both oil and grease lubricated machines. For grease-lubricated machines, a fair rule of thumb is that the temperature of the grease is about 10 C (18 F) higher than the housing temperature. For walk-around temperature measurements, be sure to take your readings from the same place each time.

Air in a lubricant can be a very dangerous contaminant (particularly in hydraulic systems). The presence of entrained air increases the rate of oxidation. In hydraulic systems, it can cause spongy response and vapor lock, and lead to adiabatic compression-induced thermal failure of the product. Checking for air contamination is a visual inspection. Look for excessive opacity (cloudiness), which can signal a high degree of mechanical agitation or a failure of the oil to release its air (possibly due to a reduction in surface tension). Also, look for excessive foaming, particularly in hydraulic systems and gearboxes. Foam compromises a lubricant’s heat dissipation properties and, in extreme cases, can exit the sump or reservoir to create slip-fall and fire hazards.

3. Lubricant and Lubrication Health Targets Met

To effectively function as a lubricant or hydraulic fluid, the product must be present in sufficient quantity and be healthy with respect to its physical, chemical and performance properties. For all lubricated machines, the number that have the correct amount of oil based upon site-glass, bullseye, or dipstick inspection is divided by the total number of oil-lubricated machines. For those oil-lubricated machines, we divide the number with no alarm for oxidation, additive depletion, thermal degradation, or cross-mixing with the wrong oil (cross-mixing could just as easily be included in contamination control). I would also add transformer oil to this group. This oil serves as a dielectric medium (insulator) in transformers. As it degrades, however, a transformer oil’s dielectric strength diminishes and potentially flammable volatile organic compounds (VOCs), such as acetylene can be formed. Therefore, transformer oils should be added to the inventory of practices equation.

For grease-lubricated systems, we rely primarily on surface-borne ultrasonic analysis tools. In properly lubricated bearings, a heterodyned signal of ultrasonic acoustic emissions at about 30 kHz produces a swishing sound of white noise and a decibel (dB) reading that’s normal for the application (baseline-dependent). If the ultrasonic noise level increases beyond a specified limit, the dB reading increases. If the lubricant is further compromised, one will hear the cracking sound of asperity contacts, because the rolling elements are contacting the raceways.

To determine if lubricant and lubrication health targets are being met, simply divide the number of bearings that are compliant on the dB reading and not exhibiting any cracking sounds associated with surface-to-surface contact by the total number of grease-lubricated bearings being monitored. If you want to refine this number, you may subtract the bearings that are defective per vibration analysis, because we’re primarily focused on the proactive aspects of machine health.

BTW: If you really want to get sophisticated with the health of grease-lubricated machines, check into some of the innovative grease-analysis techniques pioneered by Rich Wurzbach and team at MRG Laboratories (www.mrgcorp.com).

IN CONCLUSION

It’s difficult to conceive of world-class asset-reliability management without a solid foundation of great lubrication practices. OLE focuses upon driving the fundamental behaviors necessary to achieve lubrication excellence. Get your lubricants and hydraulic fluids working for you, and not against you, ASAP. And say “Olé” to Overall Lubrication Effectiveness.

Next week, we’ll tackle Overall Vibration Effectiveness (OVE).TRR

ABOUT THE AUTHOR

Drew Troyer has over 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 300 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees. Drew, who also earned a Master’s degree in Environmental Sustainability from Harvard University, is very passionate about sustainable manufacturing. Contact him at 512-800-6031, or email dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, metrics, key performance indicators, KPIs, lubrication, lubricants