In Part 1 of this series on the second element of Overall Equipment Effectiveness (OEE), we discussed Yield/Speed as the ratio of the actual production rate divided by the Highest Sustained Rate (see ink below). We also raised another important issue about this metric: Unlike Availability and Quality (OEE’s other elements), Yield/Speed (when based on the conventional formula) can mathematically exceed 100% when a system’s Highest Sustained Production rate is exceeded. This situation creates a mathematical dilemma when calculating Overall Equipment Effectiveness.

Click Here To Read The Referenced Part 1

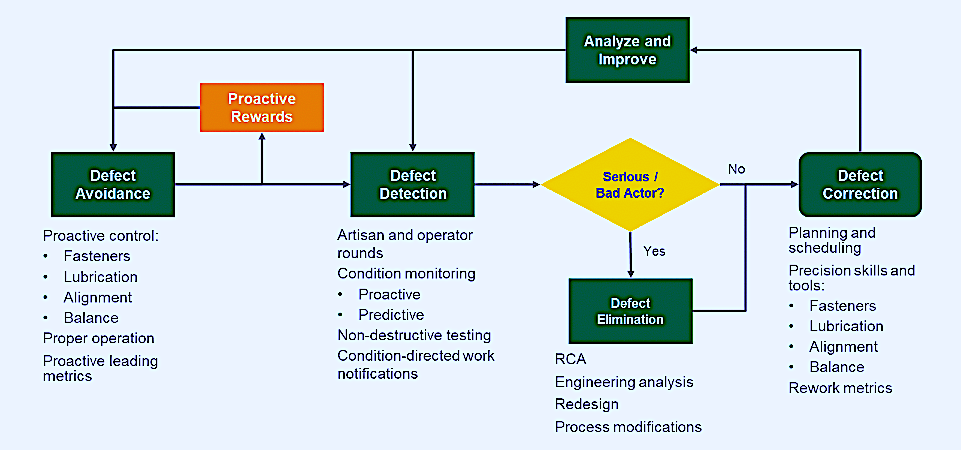

OEE is intended to have a maximum value of 100%, which represents perfection. In response, I’ve proposed a variation to the standard formula for determining Yield/Speed, whereby the absolute value of any deviation from the Highest Sustained Rate of production is subtracted from the Highest Sustained Rate, which is divided by the Highest Sustained Rate of production and multiplied by 100 to present Yield/Seed as a percentage.

My modification to the standard Yield/Speed formula is presented in Form 1. For example, if the Highest Sustained Rate is 1,000 units per hour, a production rate of either 800 or 1,200 would result in a Yield/Speed factor of 80%.

Form. 1. The Troyer workaround formula to eliminate the possibility

that the Yield/Speed metric can exceed 100%.

As with Availability, Yield/Speed losses can be equipment-induced, production/operations-induced, or market/marketing-induced. Moreover, like Availability, Here, we’re focusing on some common equipment-induced causes.

EQUIPEMNT-INDUCED OEE LOSSES

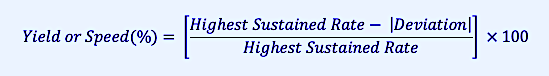

The primary causes for equipment-induced forced derating of a machine include insufficient/excessive or poorly executed preventive maintenance, wrong or insufficient machine inspection and monitoring, poor executed corrective maintenance actions, and MRO-supply-chain-quality problems or disruption (Fig. 1). Let’s explore each in more detail.

Fig. 1. Common equipment-induced causes for reduced Yield/Speed performance.

Preventive And Corrective Maintenance Problems. Preventive maintenance is essential for most assets to run trouble-free for the desired production time and at the desired production rate. If preventive maintenance practices are ineffective, it’s often necessary to slow the production rate to avoid catastrophic failure, which, in addition to production effects, could carry safety and/or environmental risks. For example, if the equipment is designed to operate at a sustained rate of 1,000 units per hour but, when we exceed 800 units per hour, it vibrates, excessively, exhibits erratic shaft orbits, overheats, leaks or reveals some other unacceptable operational irregularity, we’re faced with the choice of reduced yield or catastrophic failure. Preventive maintenance with a focus on mechanical and electrical Fasteners, Lubrication, Alignment of Balance (FLAB) will prevent these forced slowdowns and allow plants to run machines at their Highest Sustained Rate of production.

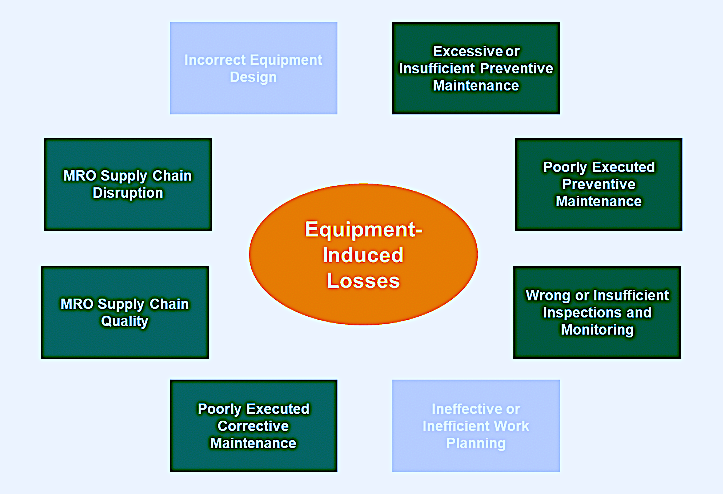

These same proactive- and precision-maintenance practices must be observed when executing corrective maintenance work. Proactive and precision maintenance is central to the Defect-Management Process (Fig. 2). This process includes methods to avoid and prevent defects, effectively detect defects, and correct defects. For serious or bad-actor defects, we employ event-based methods to analyze and eliminate defects. This process is addressed in detail in the article “A Closed-Loop System For Defect Management” (see link below).

Click Here For The Referenced Closed-Loop Defect-Management Article

Fig. 2. Defect-Management Process, including avoidance, detection, and correction as routine elements

and elimination as an exception/event-based element.

I’ve authored numerous articles on proactive and precision maintenance for The RAM Review. A summary of what I call Optimum Reference States (ORS) for Precision Maintenance that should be applied to both preventive and corrective maintenance. can be found in the linked article below. (Related articles may be accessed through the “Cut the FLAB” tab in the “Featured Categories” list on the right side of TheRAMReview.com website.)

Click Here To Read The Author’s Optimum Reference States (ORS) Article

Wrong Or Ineffective Inspections And Monitoring. In most modern industrial facilities, inspections and monitoring drive decisions on preventive and corrective maintenance. Many end-users have found that conventional time/cycles/distance-based methods for determining when to execute preventive maintenance or system rebuilds involve too much guesswork and, in some cases, adversely affect operational reliability. Bottom line: We must select the right inspections, execute them at the right interval, apply the right target or alarm criteria, utilize the right methods and tools, and execute with the right attitude. These are the “Rights” of inspections and monitoring. If these Rights aren’t observed, we fail to schedule the appropriate maintenance actions to prevent the machines from vibrating excessively, overheating, and/or exhibiting other signs of instability that force us to reduce the Yield/Speed to prevent catastrophic damage.

MRO Supply Chain Problems. In addition to effective inspections and monitoring and properly executed preventive and corrective maintenance, equipment performance depends upon a reliable maintenance, repair, operations (MRO) supply chain. We must have the right parts, stored in the right conditions, delivered at the right time, and installed using the right tools and methods and with the right attitude. These are the “Rights” of MRO-supply-chain management. If these Rights aren’t observed, all elements of OEE, Availability, Yield/Speed, and or Quality could suffer. To be specific regarding Yield/Speed, I’ve seen instances where personnel were forced to employ a “substitute” part that would work. In turn, though, the production rate had to be reduced to avoid excessive vibration, overheating, or some other unacceptable operating condition.

In some instances, correct parts are available, but the quality of the supplier is suspect. Procurement teams are directed to reduce the acquisition cost of parts and materials (and often rewarded for it). This frequently results in the sourcing of items from aftermarket suppliers that may not offer the same quality as original equipment manufacturers (OEMs). It’s an admirable objective to save money. If, however, this savings comes at the price of quality and forces us to reduce the production rate to avoid asset destabilization, procuring from the cheaper source is generally a poor economic decision.

Poor MRO-parts quality can also cause us to derate production to avoid unstable operations. Sometimes the parts were good when purchased but were stored incorrectly. When exposed to excessive contamination (dirt, moisture, etc.), sunlight and extreme temperatures (high or low), vibration, and the like, stored parts can become rusty/corroded, and subject to fretting wear, etc. Chemicals, including rubber products, degrade as a function of time, temperature, and exposure to other chemical products and ultraviolet light, among other things. When faulty products and/or parts are installed during maintenance, machines can become unstable at the Highest Sustained Rate of production and must be derated to avoid catastrophic failure.

CONCLUSIONS

Yield/Speed, the second element of Overall Equipment Effectiveness (OEE) is, in my opinion, the trickiest of the three OEE elements because it’s possible to exceed 100% Yield/Speed when employing the traditional calculation method. Using my proposed method, which subtracts the absolute value of any deviation from the Highest Sustained Rate of production to calculate Yield/Speed, solves this problem.

Yield/Speed slowdowns can be due to equipment-, production/operations-, or market/marketing-induced causes. Causes for Yield/Speed losses must be carefully categorized and tracked so they can be analyzed and managed. In this article, we’ve addressed applicable equipment-induced causes, including maintenance, inspections and MRO parts availability and quality. Next week, we’ll address production/operations-induced causes for poor Yield/Speed and OEE performance.TRR

REFERENCES

Troyer, Drew (2008-2021). Plant Reliability in Dollars & $ense Training Course Book

ABOUT THE AUTHOR

Drew Troyer has over 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 300 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. A Certified Reliability Engineer (CRE) and a Certified Maintenance & Reliability Professional (CMRP), he holds B.S. and M.B.A. degrees. Drew, who also earned a Master’s degree in Environmental Sustainability from Harvard University, is very passionate about sustainable manufacturing. Contact him at 512-800-6031, or email dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, metrics, key performance indicators, KPIs, Yield/Speed, OEE