by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Oct 17, 2020 | Asset Management, RAM Tools & Methods

The concept of stress vs. strength “interference” is important in the field of reliability engineering. This concept is so simple that one could almost call it naïve. However, minimizing interference between stress and strength in the plant often results in a clash...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 17, 2020 | Motors & Drives, RAM Tools & Methods

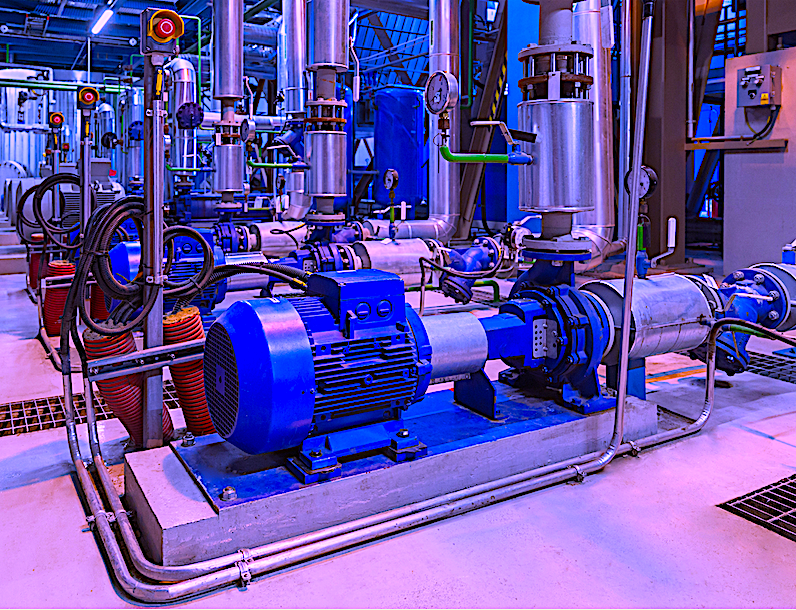

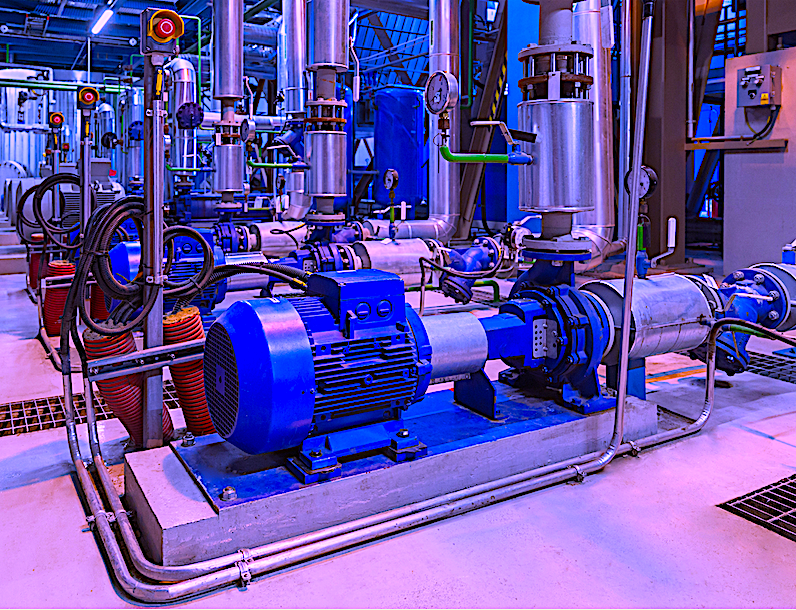

In the most basic of terms, an electric motor is a simple device that converts electrical energy into rotary motion that when transmitted to a driven load will perform mechanical work. If applied correctly, the motor will run effortlessly. If set up correctly, the...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Oct 3, 2020 | Plant Operations, RAM Tools & Methods, RAM's Human Factor, Workforce Issues

I have written extensively in The RAM Review about the importance of precision-work instructions to ensure high-quality maintenance work. Such instructions are particularly valuable for bringing in a successful shutdown, turnaround, or outage (STO) event. The...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Oct 3, 2020 | RAM Tools & Methods, The Sustainable Plant

We work in a sea of ever-churning reliability acronyms, buzz words, and descriptive labels with multiple meanings. It’s not easy to effectively communicate with our peers or, worse yet, with top management when we use uncommon terms with assumed meanings. Such...

by Heinz Bloch, P.E., Editor | Sep 26, 2020 | Plant Operations, RAM Tools & Methods, The Bloch Files

We’re using this space to wrap up our short series on the importance of machinery-quality assessments (MQAs) that began on Sept. 4, 2020 (see list of previous articles below). The overall message: MQAs can be an important tool for those seeking to zero in on...

by Heinz Bloch, P.E., Editor | Sep 17, 2020 | Plant Operations, RAM Tools & Methods, The Bloch Files

This technical note on seal-flush plans is part of my series on machinery-quality assessments (MQAs) for The RAM Review. It’s a follow-up to the most recent article in that series, “An MQA Approach to Seals and Flush Plans” (Sept. 12, 2020)....

by Tim Dunton, CMRP, CMRT | Sep 16, 2020 | Asset Management, RAM Tools & Methods

In a recent article (Aug. 28, 2020), we focused on the importance of correcting soft foot on the machines in our plants and facilities. Here, we focus on the proper ways to check for and eliminate it. As we discussed previously, soft foot is the condition that exists...

by Heinz Bloch, P.E., Editor | Sep 12, 2020 | Plant Operations, RAM Tools & Methods, The Bloch Files

This article is based on a real-world situation related to to my recent article (Sept. 4, 2020) on the value of machinery-quality assessments (MQAs) in selecting best-available technologies for plant applications. Here, I discuss how a former manager’s feedback...

by Heinz Bloch, P.E., Editor | Sep 4, 2020 | Plant Operations, RAM Tools & Methods, The Bloch Files

A reliability professional’s workday is almost entirely proactive. Such individuals are quasi “Fire Preventers;” they are not “Fire Fighters.” They use much of their available time to obtain answers to three questions: 1. Is an upgrade possible or do we...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Sep 4, 2020 | Planning & Scheduling, RAM Tools & Methods

W. Edwards Deming once stated, “In God we trust, all others must bring data!” For some, data is a four-letter word, and the value of collecting and recording it and the evidence associated with an asset failure event is often poorly understood. Old-school thinking...