by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 10, 2020 | Lubrication Corner

In 1966, at the height of the “swinging sixties” movement, the world of lubrication, friction, and wear finally received worldwide recognition as a scientific entity responsible for continued machine health and asset longevity. In retrospect, such recognition...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 3, 2020 | Lubrication Corner, RAM Tools & Methods

In the maintenance world, tools are indispensible in that they allow a maintainer to perform and complete work in a safe, consistent, and efficient manner (see article “Using the Right Tool for the Job”). When we think of tools, most will immediately picture a...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | May 22, 2020 | Asset Management, Lubrication Corner

Throughout their working life, lubricants are subjected to a variety of negative influences that can include load induced shear stress, thermal degradation, water contamination, aeration, wear metal catalyzing, and contamination from dirt, chemicals, and mixing with...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 14, 2020 | Lubrication Corner, Maintenance Management

There are few definitive studies on rolling-element bearing reliability /life that are based on industry uses and working conditions. There are, however, many claims that indicate the vast majority of such bearings never achieve their engineered-life rating (some...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 25, 2019 | Lubrication Corner, The Sustainable Plant

The search for the right environmentally friendly lubricant (EFL) is an ongoing pursuit in many plants. The results of such quests can differ greatly, depending on an organization’s understanding of the type of product it is actually seeking and how it is to be used....

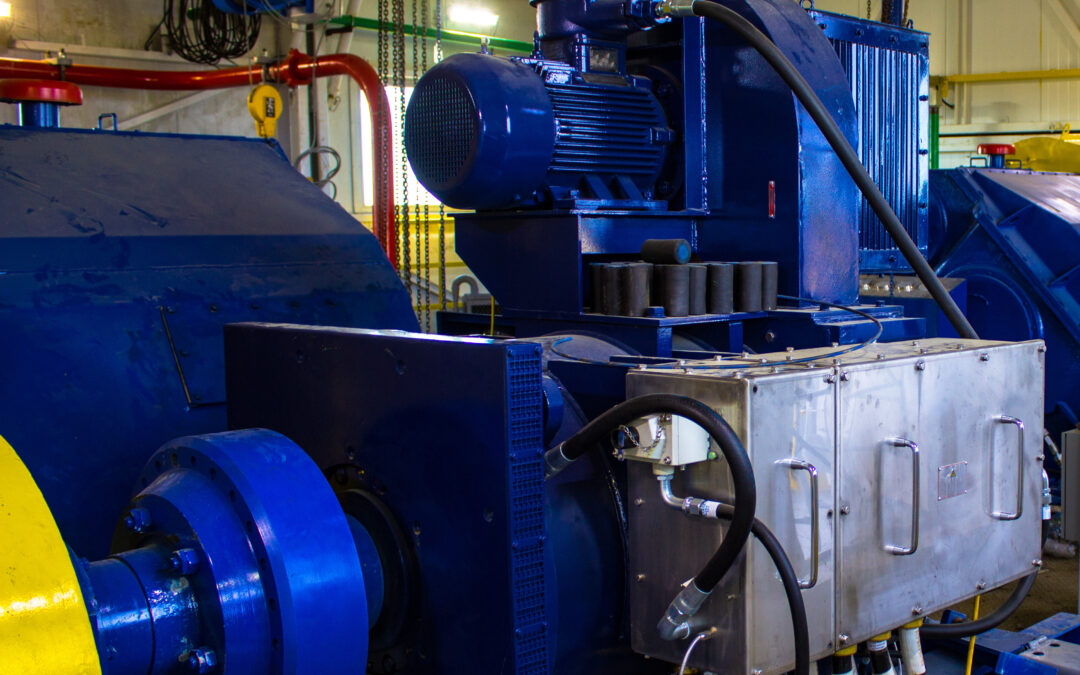

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 11, 2019 | Lubrication Corner, RAM Tools & Methods

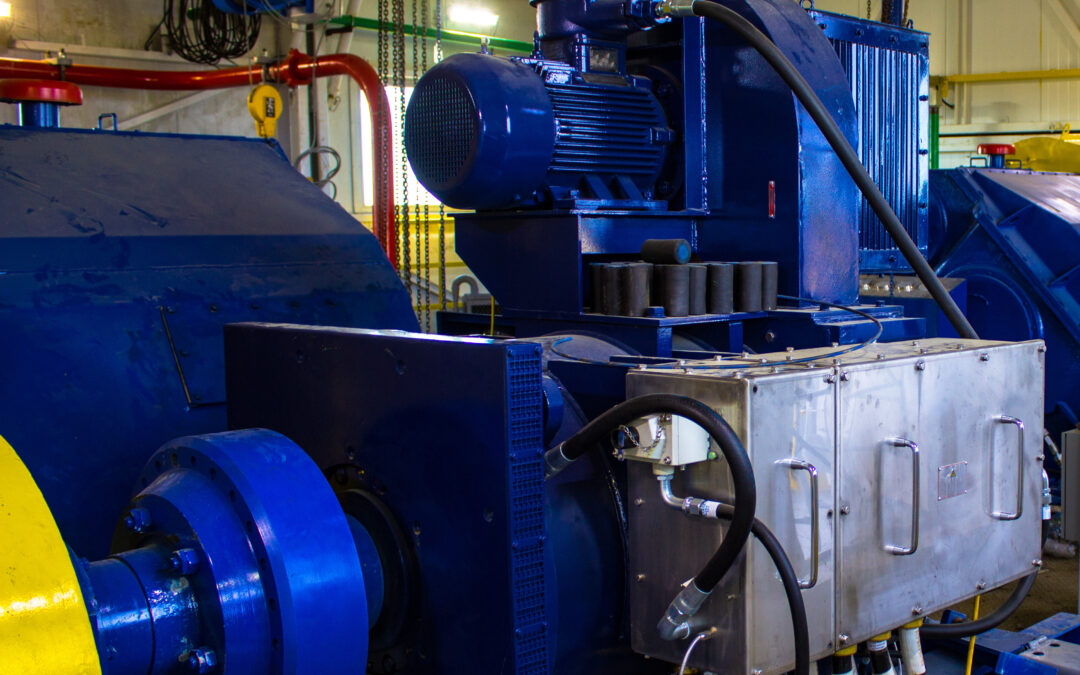

When it comes to harsh working environments, the resource sector reflects some of the most brutal. In light of such conditions and the typically remote locations of these operations, equipment reliability is paramount. Although this article focuses on the resource...

by Jane Alexander, Managing Editor | Oct 3, 2019 | Asset Management, Lubrication Corner

Have you checked to make sure that your plant’s equipment is breathing properly? According to Trent Phillips, CRL, CMRP, you should. The Global Reliability Manager at Novelis (Atlanta), Phillips discussed the issue of poor equipment breathing in a recent blog post...